Emax: Afsløring af den reelle styrke af et lithiumdisilikatmateriale som LiSi Press

Denne lithium disilicate material, Emax, isn’t just another glass-ceramic; it was a revolution in a small ingot. It blended strength and beauty in a way I had never seen before.

In this post, we’ll explore what makes this material, Emax, so special. We will look at its amazing Bøjningsstyrke and how it gets that strength from its tiny crystal structure. If you are a dentist, a lab technician, or even a patient curious about the krone in your mouth, this article is for you. I’ll break down the science into simple terms and share what I know about this game-changing material, including other great products like LiSi Press.

Indholdsfortegnelse

What Is Lithium Disilicate, Anyway?

Let’s start with the basics. What is Litiumdisilikat? At its heart, it’s a type of glass-ceramic. Think of it as a special kind of glass filled with a huge number of tiny, needle-shaped crystals. The specific chemical formula is Li2Si2O5. This is important because it’s the key to its strength. These keramik are part of a family of Dentalmaterialer that have transformed how we restore teeth. The company Ivoclar Vivadent was a true pioneer in this field, and they really set the standard for what these materials could do.

Før Litiumdisilikat, vores all-ceramic options were mostly weaker porcelæn. They looked nice but could chip easily. This new lithium disilicate glass ceramic promised both beauty and power. It has excellent Biokompatibilitet, which means it’s safe and gets along well with the tissues in your mouth. This makes it a top choice in genoprettende tandpleje. Den Litiumdisilikat itself is very stable.

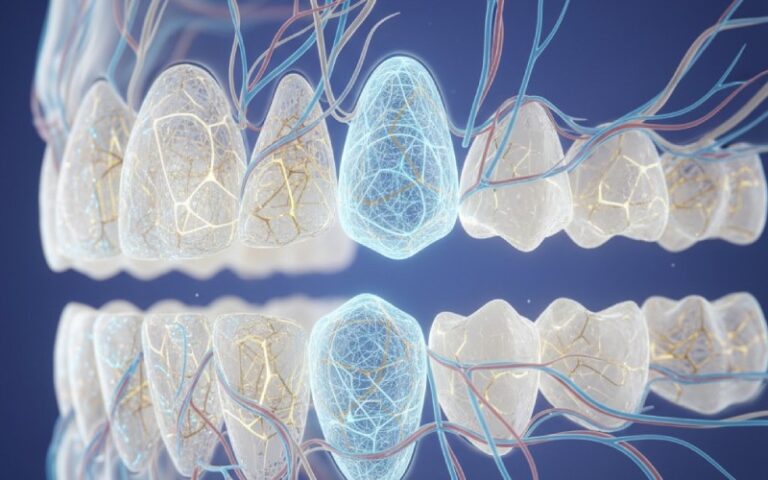

Disse keramiske materialer are made through a controlled process of heating. This process creates a dense network of Li2Si2O5 crystals inside a glassy matrix. This structure is what stops cracks from spreading. So, when you choose a Litiumdisilikat krone, you’re getting a material that is designed from the molecule up to be tough and long-lasting. It’s one of the most trusted materials available for dental restorations i dag. Lithium disilicate is also known for its great bond to tandstruktur.

Why Is Emax So Popular in Modern Dentistry?

So why did Emax become the celebrity of the Tandpleje world? For example, a patient with a cracked front tooth needs a perfect, æstetisk result. A traditional porcelæn facetter feels risky. A stronger material like zirkonia wouldn’t have the same Gennemsigtighed. When choosing to use an Emax restaurering, the result is incredible. You can’t tell which tooth is the krone and which were natural.

The popularity of Emax comes from this amazing balance. It has the high Bøjningsstyrke needed for a bageste tooth but also the beautiful esthetics needed for an anterior facetter. This versatility is a huge advantage. You can use this single lithium disilicate material for a wide range of jobs, from a full krone to a thin facetter or even an inlay. This makes life easier for both the dentist and the Dentallaboratorium. The material gives us confidence that the restaurering will look good and last for a very long time.

It’s one of the most commonly used all-ceramic materials for a reason. Emax allows for minimally invasive restorations. This means we can save more of the natural tandstruktur, which is always the goal. The material can be made very thin, as little as 1.0 mm for en krone, yet still be incredibly strong. This combination of features makes Emax a go-to choice for so many situations in Tandpleje. It truly delivers on its promise of a strong and beautiful smile.

How Strong Is Lithium Disilicate? Let’s Talk Flexural Strength.

When we talk about strength in Tandpleje, one of the most important numbers is Bøjningsstyrke. What does that mean in simple terms? Imagine trying to bend a small beam of the material. The Bøjningsstyrke is the amount of force, or pressure, it can take before it snaps. We measure this force in megapascals, or MPa. A higher MPa number means a stronger material. This is a critical property for any restaurering that has to withstand chewing forces.

So, how does Litiumdisilikat stack up? The Bøjningsstyrke af Litiumdisilikat keramik is very impressive. Most Emax products have a Bøjningsstyrke of around 400 to 500 MPa. To put that in perspective, older Dentalkeramik might have a Bøjningsstyrke of only 100-150 MPa. Det betyder, at Litiumdisilikat is three to five times stronger. This high strength is why we can use it for a bageste molar krone and trust it not to break under pressure.

Denne high flexural strength is a direct result of its internal structure. The dense, interlocking crystal network I mentioned earlier acts like rebar in concrete. It stops tiny cracks from growing and causing a fracture. This gives Emax og andre Litiumdisilikat keramik the power to last for years, even in the tough environment of the mouth. The impressive Bøjningsstyrke is a key reason why Litiumdisilikat has earned its place as a top-tier all-ceramic material. The modulus is also well-balanced.

What Are the Key Mechanical Properties of Lithium Disilicate?

Mens Bøjningsstyrke gets a lot of attention, it’s not the whole story. To truly understand a material, we need to look at all the mechanical properties of lithium disilicate. One of these is Brudsejhed. Think of Brudsejhed as a material’s resistance to an existing crack spreading. Litiumdisilikat has excellent Brudsejhed due to its high crystal content. This makes the restaurering more forgiving if a small flaw develops.

Another key property is the modulus of elasticity. The modulus is basically a measure of stiffness. A material with a very high modulus is very rigid, while one with a low modulus is more flexible. The modulus af Litiumdisilikat is similar to that of natural tooth dentin. This is a huge advantage. It means that when you bite down, the Emax krone flexes in a way that is very similar to a real tooth. This reduces stress on the underlying tandstruktur and the cement holding the krone på plads.

Disse good mechanical properties combine to give Litiumdisilikat Restaureringer their fantastic holdbarhed. Den properties of lithium disilicate glass-ceramics also include good thermal expansion characteristics and Farvestabilitet. Det betyder, at restaurering won’t expand or contract too much with hot and cold foods, and it won’t change color over time. It’s this complete package of Bøjningsstyrke, modulus, and toughness that makes Litiumdisilikat so reliable.

Can It Really Look Like a Real Tooth? (A Look at Translucency and Esthetics)

Strength is great, but in Tandpleje, looks matter just as much, especially for an anterior tooth. This is where Litiumdisilikat truly shines. The secret is a property called Gennemsigtighed. Gennemsigtighed is the ability of a material to let some light pass through it, just like natural enamel.

Emax og andre Litiumdisilikat products come in various levels of Gennemsigtighed and opacity. For example, Ivoclar Vivadent makes ingots labeled HT (High Translucency) and LT (Low Translucency). An HT ingot is great for an inlay eller en facetter where you want the natural color of the tooth to show through. An LT ingot is better for a krone where you need to block out a dark underlying tooth. This control over optical properties allows a skilled technician to create a restaurering with amazing, life-like esthetics.

Den æstetisk quality is not just about Gennemsigtighed. It’s also about how the material reflects light and the fine details that can be added. The surface of a Litiumdisilikat krone can be stained and glazed to perfectly mimic the subtle textures and colors of a real tooth. This level of artistry, combined with the material’s inherent æstetisk potential, is why Litiumdisilikat is the gold standard for beautiful tandrestaureringer. The final crystalline structure is key to these esthetics.

How Do You Make an Emax Restoration? (Press vs. Mill)

So how do we turn a piece of Litiumdisilikat into a perfectly fitting facetter eller krone? There are two main ways to fabrikere an Emax restaurering: pressing and milling. Both methods are used all the time, and each has its own advantages. The choice often depends on the type of restaurering and the equipment in the Dentallaboratorium.

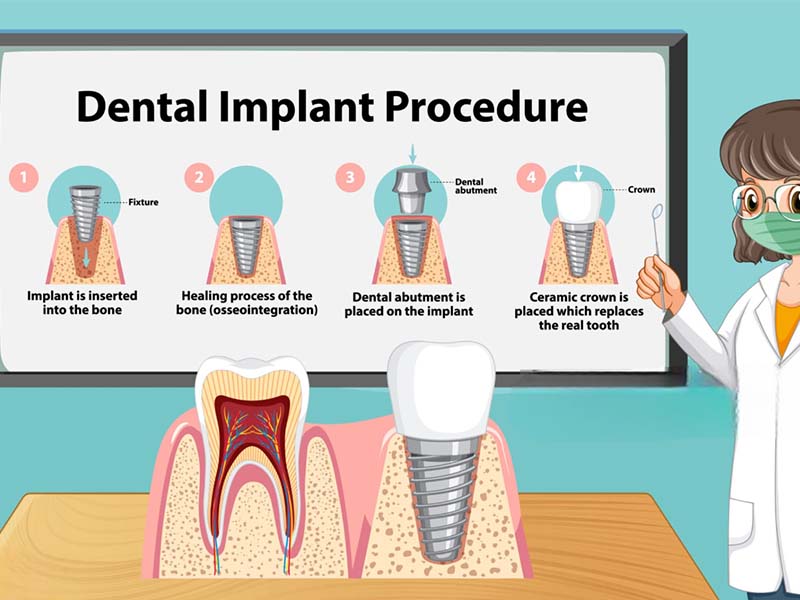

The first method is the pressing technique, which uses products like IPS e.max Press. This is a bit like the classic “lost wax” technique. First, a wax model of the krone is made. This wax model is then surrounded by an investment material. After the wax is burned away, a small Litiumdisilikat ingot is heated until it becomes like thick honey. This molten glass-ceramic is then pressed into the mold. It’s a very precise way to fabrikere a restaurering and is excellent for getting a perfect fit.

The second method is milling, which uses a CAD/CAM maskine. This is a high-tech approach. The tooth is scanned, either in the mouth (intraoral scanner) or from a model. A computer then designs the restaureringog en maskine carves the krone eller facetter out of a solid block of Litiumdisilikat materiale, such as an IPS e.max CAD block. This method is very fast and allows for same-day Tandpleje in some cases. You can Mølle a beautiful all-ceramic krone in under an hour.

What’s the Real Difference Between IPS e.max Press and CAD?

At first glance, IPS e.max Press og IPS e.max CAD might seem like just two different ways to make the same thing. But there are some key differences in the materials themselves. The main difference is the state of the Litiumdisilikat when you start. The IPS e.max Press ingot is a fully crystallized lithium disilicate glass ceramic (Li2Si2O5). It already has its final, high Bøjningsstyrke.

Den IPS e.max CAD block, on the other hand, is delivered in a partially crystallized state. It is a softer, bluish material made of lithium metasilicate crystals (Li2SiO3). This material has a much lower Bøjningsstyrke, around 130 MPa, which makes it easy for the maskine til Mølle quickly and without wearing out the tools. After the restaurering is milled, it must go into a special oven for a firing cycle. This is the final crystallization step. During this firing, the lithium metasilicate (Li2SiO3) transforms into the much stronger Litiumdisilikat (Li2Si2O5), and the krone turns into the correct tooth color.

So, which one is better? It depends. IPS e.max Press is often said to have a slightly higher Bøjningsstyrke (around 470 MPa vs. 400 MPa for CAD) and is preferred for more complex cases or a three-unit bridge. IPS e.max CAD offers incredible speed and convenience. Both methods, when done correctly, produce a fantastic and strong all-ceramic restaurering. Den fabrication method is just a different path to the same excellent result.

Are There Other Options Besides Emax? What About LiSi Press?

Mens Ivoclar Vivadent and its Emax brand are the big names in Litiumdisilikat, they are not the only players in the game. Competition is a great thing in Dentalmaterialer, and other companies have developed their own excellent lithium disilicate glass ceramics. One of the most well-known alternatives is GC’s LiSi Press. This is another pressable Litiumdisilikat that competes directly with IPS e.max Press.

LiSi Press boasts similar properties, including high Bøjningsstyrke and beautiful esthetics. Some technicians love the way the LiSi Press ingot flows and the vitality they can get in their all-ceramic restorations. It uses a similar pressing technique and is designed to create a strong, monolitisk restaurering or be layered with porcelæn for custom characterization. The existence of products like LiSi Press pushes all manufacturers to keep innovating and improving their Dentalkeramik.

Whether a lab chooses Emax eller LiSi Press often comes down to personal preference, experience, and relationships with the manufacturers. The important thing is that we have choices for high-strength keramiske materialer that allow us to provide the best possible care for our patients. This is a great time for periodontics and restorative work.

What’s the Secret on the Inside? (A Peek at the Microstructure)

I’ve mentioned the crystal structure a few times, but let’s take a closer look. The real secret to the Bøjningsstyrke af Litiumdisilikat is its microstructure. Imagine a pile of needles thrown on a table. Now imagine filling all the space between those needles with glue. That’s a simple way to picture the microstructure in lithium disilicate glass. The “needles” are tiny, elongated crystals of Litiumdisilikat (Li2Si2O5). The “glue” is the glassy matrix that holds them all together.

This interlocking crystalline structure is incredibly effective at stopping cracks. When a force is applied to the krone, a tiny crack might start in the glass matrix. But as soon as it hits one of the many Li2Si2O5 crystal needles, it has to change direction. It gets deflected and blunted. To break the material, a crack would have to find a path through this dense, tangled forest of crystals. This gives the material its amazing Brudsejhed og Bøjningsstyrke. The study of the crystallization and microstructure in lithium is fascinating.

The chemical process is also key. The heat treatment on crystallization is precisely controlled. Some research, like a vitro study on the effect of P2O5, shows how tiny additions of other chemicals can influence crystal growth. The p2o5 on the crystallization can affect the size and density of the crystals. All this science, from p2o5 and heat treatment to the final treatment on crystallization and microstructure, is done to create the ideal monolitisk structure. It’s a world away from a weaker lithium silicate som li2sio3.

Is Lithium Disilicate the Right Choice for Everything?

It is not the perfect solution for every single situation. The biggest consideration is for long-span bridges, especially in the bageste area of the mouth where biting forces are highest. While an Emax krone is great for a single bageste tooth, a bridge that replaces two or more teeth requires even more Bøjningsstyrke. Den connector areas of a bridge are where stress is concentrated.

For a long bageste bridge, a stronger material like monolitisk zirkonia is often a better choice. Zirkonia can have a Bøjningsstyrke of over 1000 MPa, more than double that of Litiumdisilikat. However, zirkonia typically has lower Gennemsigtighed, so it can be a trade-off between ultimate strength and the best esthetics. So, where is Litiumdisilikat the hero? It’s perfect for almost any single-tooth restaurering. This includes anterior og bageste crowns, veneers, inlays, and onlays.

You can also fabrikere a short, three-unit bridge with Litiumdisilikat if it’s in the anterior region (front of the mouth). The decision always comes down to the specific clinical situation. We have to consider the patient’s bite (occlusal forces), the location in the mouth (anterior vs. bageste), and the desired æstetisk outcome. But for the vast majority of all-ceramic single-unit tandrestaureringer, Litiumdisilikat materiale is a fantastic, reliable, and beautiful choice.

Ting at huske på

- Strong and Beautiful:

Litiumdisilikat(Emax,LiSi Press) offers a great mix ofBøjningsstyrke(400-500MPa) and life-likeesthetics. - Crystal Power: Its strength comes from a dense structure of interlocking

Li2Si2O5crystalneedles in a glassmatrix. - Versatile Use: It’s great for a single

krone,facetter,inlayogonlaysin both theanteriorogbagesteparts of the mouth. - Two Ways to Make: Kan være

fabricated usingapressing technique(IPS e.max Press) or milled with a CAD/CAMmaskine(IPS e.max CAD). - Not for Everything: For long bridges in the back of the mouth, a stronger material like

zirkoniais often a better choice.