Emax

As one of the top five dental labs in China, Istar Dental Lab is focused on making top-quality dental restorations for dentists, clinics, hospitals, and other labs around the world. We are experts at using advanced ceramic materials, especially our special Emax solutions, to make restorations that look great, are very strong, and last a long time.

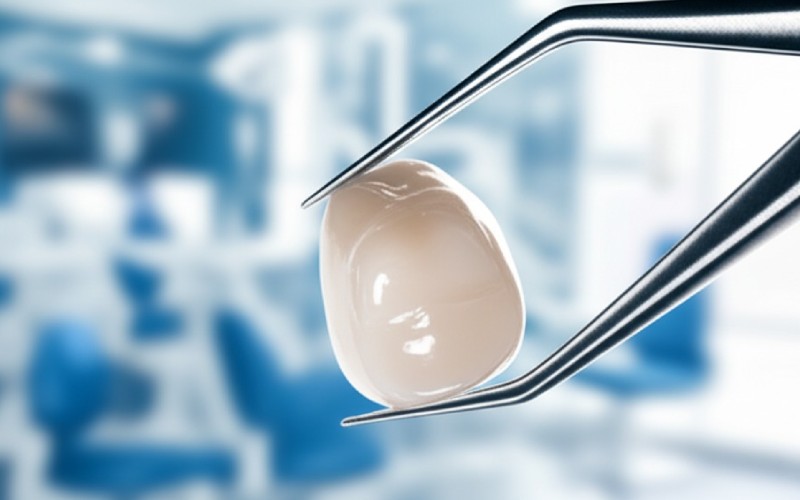

Istar Dental Lab Emax Solutions

Welcome to our Emax dental lab. We help dentists create beautiful and strong smiles for every patient. Our team of skilled dental technician professionals is here to be your trusted partner. We are a top digital dental laboratory for any dental clinic, dentist’s office, or hospital.

Why Choose Our Emax Dental Service?

When you work with our Emax dental lab, you get the best of cosmetic dentistry. We use our skills to make sure every tooth is perfect. We know you want what is best for your patients.

- Looks Real: Emax teeth look just like real teeth. They have great translucency and a life-like quality. This means they let light pass through them, just like a natural tooth. It is easy to get a perfect match with our shade matching help.

- Very Strong: These teeth are tough. They have high strength and are resistant to fractures. This is good for bruxism patients who grind their teeth. They also resist wear and chipping.

- Safe for Patients: Emax is a metal-free choice. This means it has high biocompatibility. It is safe for the body and will not cause dark lines on the gums like old Gestion des finances publiques les couronnes.

- Saves Tooth Structure: We support minimally invasive dentistry. Making an Emax tooth often means you do not have to remove as much of the healthy tooth. This is part of conservative dentistry.

Our High-Quality Emax Dental Work and Services

Notre Emax dental lab makes many kinds of all-ceramic restorations. We offer full dental lab services and can help with any case. We follow all dental industry standards and regulations.

Types of Emax Dental Prosthetics We Make:

- Emax Crowns: We make strong full contour crowns. These can be monolithic restorations or beautiful layered ceramics.

- Emax Veneers: Thin shells that cover the front of teeth. We also make occlusal veneers.

- Emax Bridges: To replace missing teeth.

- Emax Inlays: To fill cavities inside the tooth cusps.

- Emax Onlays: To fill cavities that go over the tooth cusps. These are also called partial crowns.

- Emax Implant Crowns: We make dental implant crowns that fit on a dental implant. These can be screw-retained crowns that attach to an abutment or a hybrid abutment crown.

Our lab’s procedures focus on quality control. You will always get custom dental restorations with a precise fit.

Our Modern Digital Workflow

We use the latest dental technology to give you the best results. Our process is built on digital dentistry and CAD/CAM technology.

- Scan: Our work starts by getting a very accurate digital picture, either from your intraoral scans or by us scanning the physical molds you send. We then load this digital scan into our special 64. ) logiciel, comme software, where we carefully design the new tooth.

- Conception : The design file is then sent smoothly to our CAM computer, which plans the exact path for the milling machine. After that, the tooth is automatically milled or pressed. Then, it’s heated in a special oven (sintering or crystallization) and finally, carefully stained, glazed, and polished to make it look and work perfectly.

- Create: Nous utilisons les meilleurs 64. ) logiciel, comme software known for being flexible, open to different systems, and having large tooth libraries. These programs have helpful tools like AI that finds the tooth’s edge and advanced bite-adjustment tools. For our Emax 64. ) logiciel, comme restorations, we use very precise 5-axis milling machines. These machines are needed to create the fine details and exact fit for Emax. Key features include:

- Minimum Tool Diameter: 0.6 mm, needed for capturing small details and exact edges.

- Repeatability: An excellent ±5 μm, making sure every restoration is consistently accurate.

- Spindle Speed: From 60,000–100,000 rpm, set for fast and exact milling of our ceramic blocks.

- Wet Milling: We only use wet milling to prevent tiny cracks and protect the material during milling.

- Staining and Glazing: We get a beautiful, natural look through our careful staining and glazing process. We use special ceramic stains and glazes and apply them carefully to get a natural color match. We use layering techniques, with stains inside for a deep look and on the outside for surface details. The oven temperatures (730–770°C for 10–15 minutes) are precisely controlled. This makes the color layers strong and long-lasting without making the tooth look dull.

- Quality Control Checkpoints: We check for quality at every step of our process:

- Pre-design: Checking the scan for accuracy, gaps, or errors.

- Post-design: Carefully checking the edges, digitally checking the fit, and checking the bite.

- Post-milling/pressing: Looking for any chips, checking the fit on the model, and measuring thickness (minimum 1.0 mm for molars, 0.8 mm for anteriors).

- Post-crystallization/sintering: Complete color and shade check, checking the surface for problems, and looking for tiny cracks with a microscope.

- Final Inspection: Trying the fit on the model, complete paperwork, and tracking for each part, especially for cases with multiple teeth.

Our goal for the gap at the edge is always under 50 μm for a good clinical result, and we aim for less than 30 μm. We aim for a color match with a difference (ΔE) of less than 2.0, which the human eye can’t see.

A Look at Dental Restoration Materials

It is important to use the right materials for the right job. Here is a table to help you see the differences. This shows a simple classification of dental ceramics.

| Fonctionnalité | IPS e.max (Lithium Disilicate) | Zirconia (Zirconium Oxide) | PFM (porcelaine fondue sur métal) |

|---|---|---|---|

| Main Use | Dents antérieures et postérieures | Back teeth, bridges | Couronnes et bridges |

| Les regards | Excellent, very lifelike | Good, but can be less clear | Good, but has a metal base |

| La force | Haute résistance | Very high strength | Haute résistance |

| Comment c'est fait | Milled or pressed | Broyé | Metal base with porcelain on top |

| Stabilité des couleurs | Excellent | Excellent | Good, but metal can show over time |

| Other Ceramics | A type of high-strength ceramic | Similar to alumina ceramics | Uses feldspathic porcelain |

| Previous Version | An update to IPS Empress | A popular all-ceramic choice | A traditional choice |

| Related Materials | Works with lithium silicate | A type of monolithic ceramic | Layers porcelain on metal |

Partner With Us Today

Partner with Istar Dental Lab for an easy, high-quality process to get great Emax restorations with a fast 3-7 day in-lab turnaround. Our simple process is made to work smoothly with your practice.

Our partnership starts with a meeting to learn about your needs and set up your secure account on our digital portal. We can handle any case you send, however you send it:

- Digital & Traditional Cases: Send digital files from all major intraoral scanners (STL, PLY) directly through our portal, or send traditional PVS impressions. We will immediately scan them with high-resolution scanners for the best accuracy.

- Working Together on Design and Creation: Our expert 64. ) logiciel, comme team carefully designs each new tooth for you to check and approve with a 3D model. After you approve it, we start making it using our modern equipment. It goes through many quality checks for a perfect fit, function, and look before we safely ship it to you.

Partner with Istar for an easy mix of technology, skill, and speed.