Maîtriser la zircone multicouche : secrets d’un frittage parfait et d’un bord incisal parfait

Multilayer zirconia, a material that promises both strength and beauty. But there’s a catch. Getting that beautiful, natural-looking incisal edge is an art, and the sinter process is the science behind it. In this article, I’m going to pull back the curtain. I will show you how to master this amazing multilayered material. You will learn how to make a restoration that both you and your patients will love.

Table des matières

What Exactly Is Multilayer Zirconia and Why Should I Care?

In my early days, zirconia was a strong, white block. We called it “monolithic zirconia.” It was great for back teeth because it had high flexural strength, but it looked too plain for front teeth. It didn’t have the natural look of a real tooth. Multilayer zirconia is the solution to that problem. Think of it like a stack of see-through layers. The bottom layer, near the gum line (the cervical area), is stronger and less see-through. This gives the restoration a solid base.

As you move up toward the biting edge (the incisal edge), the layers get more and more see-through. This mimics a real tooth, which has different levels of translucency. This amazing zirconia material lets us create a restoration that is strong enough to last but also beautiful enough for a front smile. For anyone in dentistry, from the technician to the clinician, this material is a game-changer. It makes our work better and our patients happier.

These advanced dental materials combine the best of both worlds. We no longer have to build up layers of weak porcelain on a strong substructure. Instead, we can mill a single block of multi-layered material. This simplifies the fabrication process a lot. The result is a tough, beautiful restoration that looks just right in the patient’s mouth.

How Does the Fabrication Process Work in Modern Dentistry?

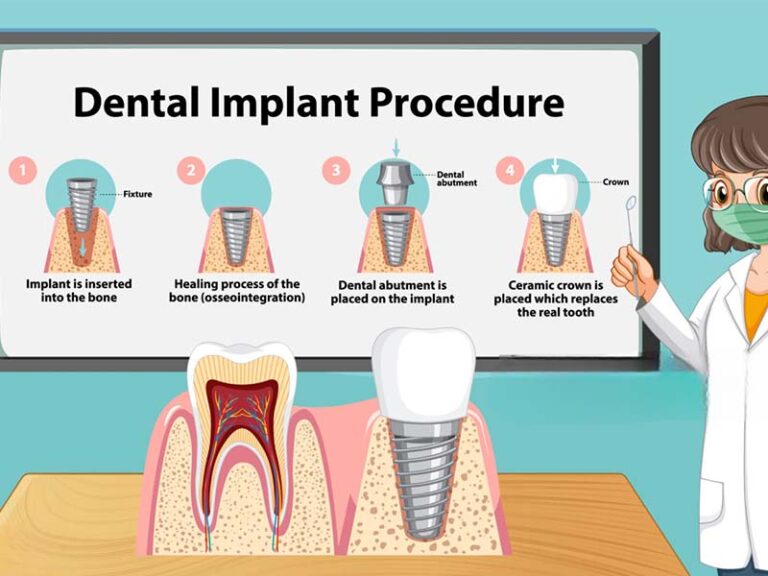

The fabrication of a multilayer zirconia crown is a high-tech process. It all starts with a digital scan of the patient’s mouth. We use this scan to design the restoration on a computer using CAD software. This is where the magic begins. The technician can see exactly how the final tooth will look before we even start. It allows for a very precise fit and shape.

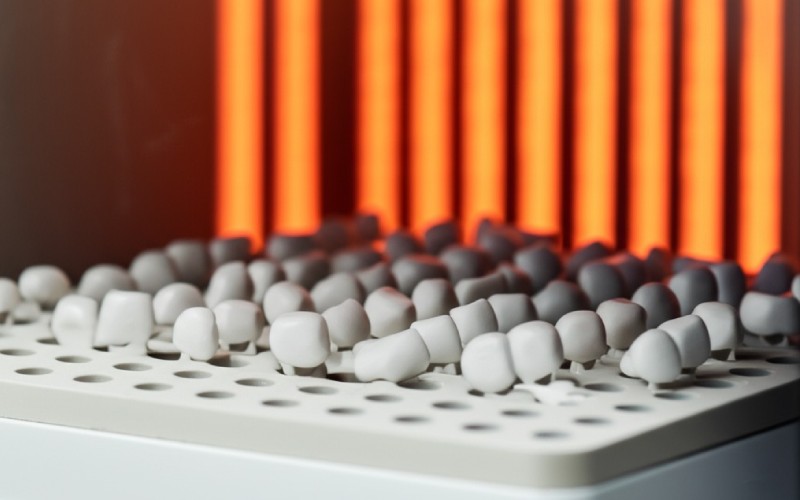

Once the design is perfect, we send it to a milling machine. The machine takes a small block of multilayer zirconia material, like Katana Zirconia or IPS e.max ZirCAD, and carves the crown. This block already has the different layers of color and translucency built into it. The machine carefully follows the digital design to fabricate the tooth shape. The crown at this stage is soft and chalky, and about 20% larger than the final size.

This “green state” zirconia is easy to adjust. I often do some light shaping here to perfect the anatomy before the most important step: the sinter cycle. This process of using CAD/CAM to mill a restoration has made dental restorations more accurate and consistent than ever before. It’s a huge leap forward in dentistry.

What Happens During the Sinter Cycle?

The sinter process is where the real transformation happens. After we mill the crown, we place it in a special high-temperature oven. The oven slowly heats up to a very high temperature, often over 1500 °C. This intense heat causes the zirconia particles to fuse together and shrink. This is called sintering, and it’s what gives the zirconia its incredible strength and final color.

A proper sinter cycle is critical. If you heat it too fast or cool it too quickly, you can create stress in the material, which might lead to cracks later. I’ve learned that patience here pays off. Following the manufacturer’s instructions for the specific zirconia material you are using is a must. The sinter cycle not only shrinks the restoration to its final size but also develops its final mechanical properties, like its flexural strength and hardness.

During the sinter process, the microstructure of the zirconia changes. The small particles bond to form a dense, hard ceramic. This process also brings out the beautiful, layered colors and the translucency of the incisal edge. When it comes out of the oven, the chalky white shape has become a hard, tooth-colored restoration ready for final touches. The success of the entire fabrication depends on getting this step right.

Why Is the Incisal Edge So Important for a Natural Look?

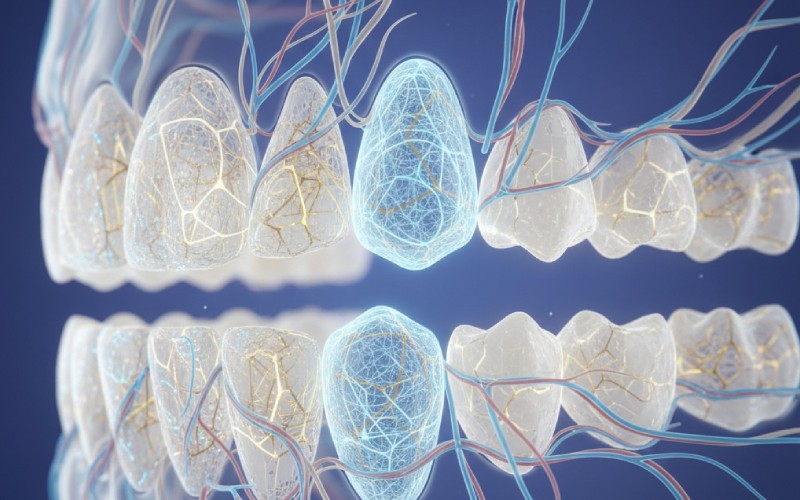

The incisal edge is the part of the tooth that does the cutting. It’s also the part people see most on the front teeth. In a natural tooth, the incisal edge is the most see-through part. It doesn’t have the dense dentin core behind it, so light passes through it. To make an artificial restoration look real, we have to copy this effect. This is where the incisal translucency of multilayer zirconia is so important.

When I create an anterior restoration, I spend most of my time on the incisal third. The goal is to create a seamless transition from the more opaque body of the tooth to the glassy, translucent incisal edge. If the incisal edge is too white or opaque, the tooth looks fake. If it’s too grey or see-through, it can look dark or dead. Getting that perfect balance is key for a lifelike appearance.

The character of the incisal edge also includes subtle things like mamelons, which are a few small bumps on the edge of new front teeth. We can add these effects to the incisal area to make the restoration look even more natural. The final look of the incisal edge has a significant impact on whether the patient feels the tooth is “theirs.” The optical properties must be perfect.

Can You Really Get Strength and Beauty from One Zirconia Restoration?

Yes, you absolutely can. This was the biggest challenge in dentistry for years. Early zirconia ceramics, like some 3Y-TZP materials, were very strong, with a flexural strength over 1200 MPa. But they were not very see-through. To make them look good, we had to layer them with weaker porcelain, which could chip. Monolithic zirconia solved the chipping problem but didn’t look great at first.

The breakthrough came with new types of zirconia material. These materials, often called translucent zirconia, have a different crystal structure. They have more of what we call the cubic phase. This change in the microstructure allows more light to pass through, increasing translucency. The trade-off is a slight decrease in strength. For example, a highly translucent zirconia might have a flexural strength of 700-800 MPa.

But here’s the good news: 800 MPa is still incredibly strong! It’s more than strong enough for almost any single crown in the mouth, including front teeth. Multilayer zirconia gives us the best of both worlds. It places the stronger, less translucent layers in the body of the tooth and the more beautiful, see-through layers at the incisal edge. This gives us both strength and fracture toughness and a beautiful final restoration. A study in 2022 showed these materials perform very well.

What Role Does Yttria Content Play in the Final Fabrication?

The “secret ingredient” in modern zirconia is an element called yttria. The amount of yttria added to the zirconia (ZrO₂) changes its properties. We often see materials labeled as 3Y-TZP, 4Y-TZP, or 5Y-TZP. The number refers to the percentage of yttria (as 5 mol% yttria, for example). This is very important for the clinician and technician to understand.

3Y-TZP is the classic, high-strength zirconia. It has about 3% yttria. It has a mostly tetragonal crystal structure, which makes it very resistant to cracks. This is the material with the super high flexural strength, often over 1200 MPa. It’s perfect for bridges and dents postérieures but is the least translucent.

As we add more yttria, we get to 4Y-TZP and 5Y-TZP. Kuraray’s Katana line is a famous example. These materials have more of the cubic phase in their microstructure. More cubic phase means more translucency. 5Y-TZP is the most translucent of all, making it amazing for front teeth where looks are most important. Its flexural strength is lower, maybe around 750 MPa, but that is still much stronger than other ceramic materials. 4Y-TZP is a great all-around material, offering a good balance of strength and beauty. It’s an intermediate option.

How Do You Characterize the Incisal Edge for a Lifelike Result?

This is where art meets science. Even with the best multilayer zirconia, the final touch of characterization makes all the difference. After the restoration comes out of the sinter oven, I examine the incisal edge. The built-in layers provide a great starting point, but I often add more detail by hand. This is a step where a good technician really shines.

I use special ceramic stains to add subtle effects. A tiny touch of blue or violet stain along the incisal edge can increase the illusion of translucency. A little bit of white can mimic natural color variations. The goal is to break up the uniform color and create a more natural, varied appearance. I might also add some texture to the surface to control how light reflects off of it, which affects the perceived roughness.

Sometimes, a technique called a “micro-cutback” is used. This involves removing a tiny bit of the zirconia at the incisal edge and filling it with a special translucent porcelain. This gives the ultimate lifelike effect. However, with today’s excellent multilayered zirconia, this is needed less often. Careful staining and glazing are usually enough to create a stunning and durable incisal edge on the restoration. This final characterization is key to a happy patient.

What Does the Microstructure (SEM) Tell Us About Our Work?

A scanning electron microscope, or SEM, lets us see the microstructure of the zirconia up close, at thousands of times magnification. Looking at SEM images teaches us a lot about our materials and processes. For example, a 2022 study used SEM to analyze the topographic surface of different zirconia types.

When we look at a well-sintered piece of zirconia under an SEM, we see a dense, tightly packed structure of grains with very few pores. This dense microstructure is what gives the material its high flexural strength. If the sinter cycle was too short or not hot enough, an SEM image might show more pores and a less dense structure. This would tell us the mechanical properties are not as good as they should be.

SEM images also show us the different grain sizes between 3Y-TZP and 5Y-TZP materials. The higher yttria materials often have a larger grain size and a mix of crystal shapes. This is what changes the optical properties and increases translucency. Looking at these SEM pictures, like the ones in Figure 3 of many research papers, helps me understand exactly why one zirconia material behaves differently from another. It confirms that our daily work in the laboratory is based on solid science.

How Does Aging Affect These Zirconia Restorations in the Oral Environment?

One of the biggest concerns with any dental material is how it will last over time. The mouth is a tough place. It’s warm, wet, and deals with a lot of force. For early zirconia, there was a concern about something called low-temperature degradation or “aging.” This is a process where water can slowly cause a monoclinic transformation in the zirconia’s crystal structure, which could weaken it.

Luckily, modern zirconia materials have been improved to resist this. Many studies, including some from 2022, have performed artificial aging on materials like 4Y-TZP and 5Y-TZP to simulate years of use in the oral environment. These studies use tests that expose the zirconia restorations to steam and pressure. The results are very encouraging. They show that the newer zirconia types have excellent aging resistance.

The addition of more yttria in 4Y and 5Y materials helps to stabilize the cubic phase, making them much less prone to this degradation. In a recent vitro investigation, the amount of monoclinic transformation after aging was very low. The mechanical properties remained high. This means we can be confident that a well-made multilayer zirconia restoration will stay strong and stable in the patient’s mouth for many, many years. 5Y-TZP was less prone to this issue.

What Are My Top Tips for Flawless Zirconia Fabrication in the Laboratory?

If you work in a laboratory or as a clinician overseeing these cases, here are my best tips for success. First, always know your material. A 4Y-TZP does not sinter the same way as a 5Y-TZP. Read the instructions from the maker (like Kuraray or Ivoclar Vivadent GmbH) and follow them exactly.

Second, pay attention to the pre-sintered state. This is your best chance to perfect the shape and texture. Handle the green-state zirconia gently. Don’t touch it with oily fingers. Make sure your milling burs are sharp to avoid creating micro-cracks. A little bit of care here prevents big problems later. This step is a key part of the fabrication.

Finally, master the art of the incisal edge. Use the multilayer zirconia to your advantage. Position the restoration in the block so the transition from the cervical to the incisal area looks natural. After the sinter cycle, use stains and glazes to enhance the translucency and add character. Don’t be afraid to add a hint of blue or amber to the incisal edge to make it pop. A great restoration is a team effort between the clinician and the technician.

To Sum It All Up, Here’s What to Remember:

- Choose the Right Material: Use high-strength zirconia (like 3Y-TZP) for bridges and high-translucency zirconia (like 5Y-TZP) for front teeth where looks matter most. MT Multi-layered blocks are often a great choice.

- Trust the Process: The CAD/CAM fabrication process is very accurate. Follow a precise sinter cycle according to the manufacturer’s guide to ensure good mechanical properties.

- The Incisal Edge is Key: The incisal one-third of the tooth is critical for a natural look. Use the built-in layers and enhance them with stains to create realistic translucency.

- Strength and Beauty Are Possible: Modern multilayer zirconia provides excellent flexural strength (over 700 MPa) and amazing looks in one material.

- Aging is Not a Major Concern: Newer zirconia materials with more yttria show excellent resistance to degradation in the oral environment.