Istar: The Premier Arch Dental Lab

As Istar Dental Lab, a top provider of dental laboratory services and one of the five best dental labs in the world, we are here to support dentists, dental clinics, hospitals, and other labs with the best products and services for the dental arch.

01.

Comprehensive Services

More than just fabrication, our services encompass the entire digital workflow: from precise digital modeling and design, through advanced manufacturing processes and meticulous material selection, to comprehensive technical support. We are committed to delivering customized, precise, and esthetically superior solutions to meet the diverse needs of our global clientele.

02.

Cost Control & Competitive Pricing

Compared to traditional techniques, our digital methods reduce material waste by 30-60%. Over time, these digital processes also lower labor costs by 20-40% and material costs by 10-30%. This efficiency allows us to offer you high-quality products at a more competitive price.

03.

Enhanced Efficiency and Convenience

Our digital methods are exceptionally precise, resulting in a better fit and fewer chairside adjustments. Our advanced production processes have dramatically reduced turnaround times for restorations from weeks to as little as 48-72 hours in many cases.

Your Trusted Partner for Arch Dental Lab

With over 10 years of experience, Istar Dental Lab is a leading arch dental lab in China.

At Istar Dental Lab, we use the latest digital methods, including advanced CAD/CAM systems, new 3D printing technology, and AI to help with design. This makes sure our work is accurate, fast, and gives patients great results. We are serious about quality control, follow all international rules, and are always innovating. This keeps us at the top of our field.

We believe in good communication with our dental lab partners. We are more than just a lab; we are your partner. We are run by a team of experts, from the Dentist and Oral Surgeon advisors to our skilled technicians. Our work is precise, from the articulated casts to the final occlusion check.

Let’s work together. You can trust our dental laboratory technology. Let our work speak for itself. You will see the benefit in your happy patients.

10+ years of manufacturing experience

10000 square meters of modern dental lab

300 technicians with various advanced machines

Latest Full Arch Cases From ASD Dental Lab

Istar Dental Lab offers a complete set of products and services for the dental arch, all carefully designed to meet the needs of our partners around the world. We offer fixed, removable, orthodontic, and implant prosthetics, and each one is backed by our modern digital design, manufacturing, and tech support.

The Technology Behind Your Smile Design

At Istar Dental Lab, our focus on technology is key to providing great dental arch solutions. We use the newest tools in digital dentistry to change how we make things, improving our accuracy, speed, and efficiency.

Our digital dentistry services include:

- CAD/CAM dentistry: Using CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) and 3D printing is at the heart of what we do. We use top CAD software that allows for advanced scanning and design. This lets us:

- Digital impressions: Send us files from your intraoral scanner. We make perfect dental models from them.

- 3D printing in dentistry: We use different 3D printing technologies for specific jobs:

- SLA (Stereolithography) and DLP (Digital Light Processing): Best for models, surgical guides, splints, and temporary restorations because they are very accurate, smooth, and fast for making many at once.

- Material Jetting: Used for making realistic, multi-material, full-color models for planning and showing to patients.

- Dental milling: High-precision milling machines are used to make restorations from blocks of zirconia, lithium disilicate, PEEK, and metal. This process ensures a great fit and accurate shape.

Materials Science in Dental Arch Applications

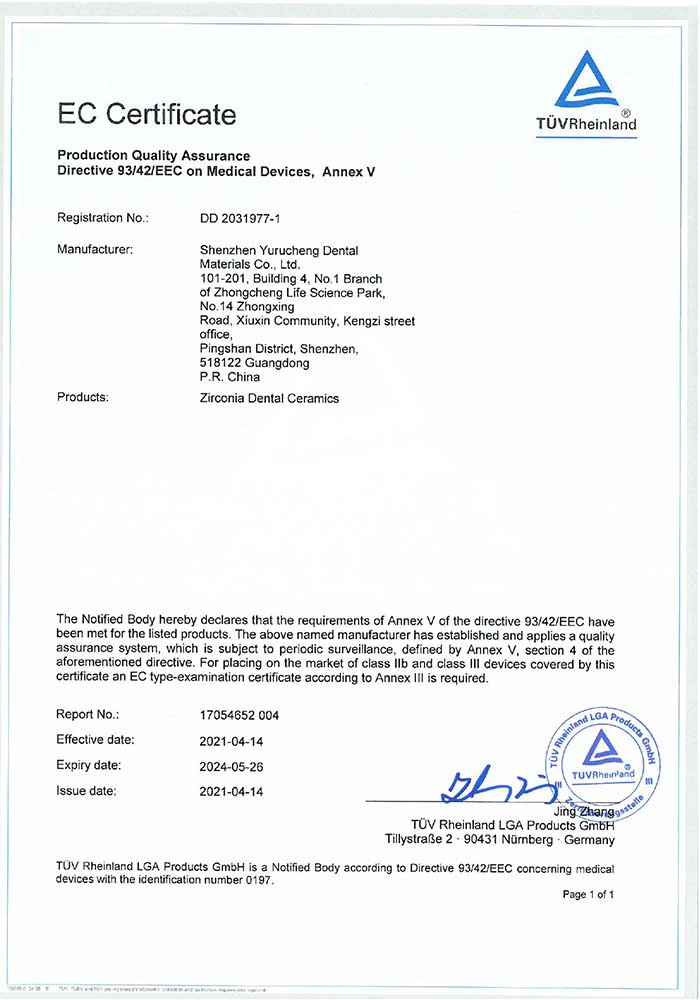

Zirconia (including Y-TZP, 3Y, 4Y, and 5Y types) is a key material for our fixed products.

- Mechanical Strength: Monolithic zirconia (3Y-TZP) is exceptionally strong, making it perfect for back teeth that take a lot of pressure and for long bridges.

- Esthetics: 5Y-PSZ zirconia is nearly as translucent as lithium disilicate, making it a good choice for teeth in the smile zone.

- Clinical Indications: Recommended for full-arch sets of teeth, multi-unit bridges, and implant-supported frames because it’s very strong and gentle on opposing teeth (when polished).

- Multi-layered and Gradient Materials: We use multi-layered zirconia that has gradual changes in color and translucency to look like a natural tooth, which means less need for staining.

- Processing: It is usually milled and then heated at very high temperatures (1450–1550°C). The final properties depend on a very precise heating process.

- Clinical Performance: Studies show a 5-year success rate of over 95% for monolithic zirconia crowns and bridges, with very little chipping or breaking.

- Bonding: It needs to be air-blasted and used with special resin cements for the best bond.

E.max (Lithium disilicate) is a top choice for restorations that need to look amazing.

- Mechanical Strength: It is strong enough for single crowns and short bridges in both the front and back of the mouth.

- Esthetics: It’s still the gold standard for looks, letting light pass through beautifully and matching tooth shades very well, especially for front teeth.

- Clinical Indications: Best for single crowns, veneers, and short front bridges.

- Processing: It is milled in a “blue” state and then heated to about 850°C. This firing gives it its final strength and look.

- Clinical Performance: Crowns have a 5-year success rate of over 94% with excellent-looking results.

- Bonding: It can be etched and treated to create a strong bond, which allows for smaller tooth preparations.

PEEK is an advanced polymer that is becoming popular for its special qualities.

- Applications: It’s being used more for implant-supported frames and removable denture bases.

- Properties: It’s strong, light, and has an elasticity closer to bone than metal, which feels more natural.

- Biocompatibility: It is very safe and causes almost no irritation.

- Esthetics: It is tooth-colored and can be layered with other materials to look even better.

- Wear: It wears down less than PMMA and is gentler on opposing teeth than metal.

- Processing: It is usually made by milling it with CAD/CAM.

PMMA is still a useful and affordable material.

- Applications: It’s the standard for temporary crowns, bridges, and denture teeth. New methods now allow it to be 3D printed for final denture bases.

- Properties: It’s easy to work with, low-cost, and looks good.

Processing: It can be made with traditional methods or 3D printed, which allows for a completely digital denture process.

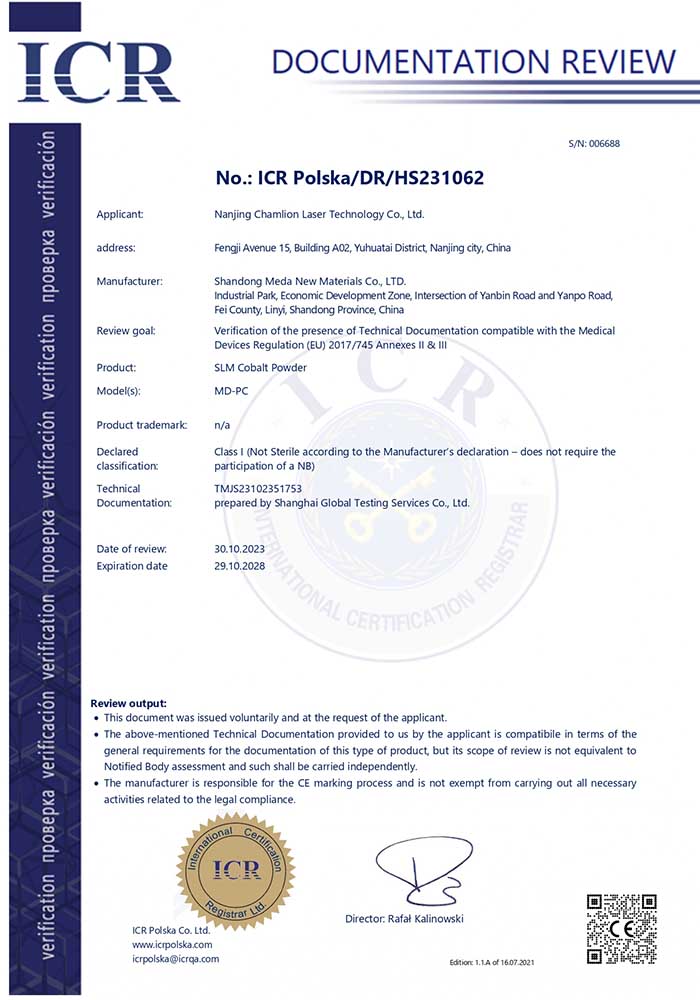

We use different metal alloys for their strength, long life, and specific uses.

- Cobalt-Chrome (CoCr) Alloys: The main material for removable partial denture (RPD) frames and some fixed restoration frames.

- Properties: Very strong and does not corrode easily.

- Processing: More and more, it’s made using 3D printing (additive manufacturing or AM), specifically selective laser melting (SLM). This allows for very accurate, lightweight, and complex frames that fit better.

- Titanium and Titanium Alloys (Ti-6Al-4V): The top choice for dental implant posts and abutments.

- Properties: Excellent safety for the body, great osseointegration, and strong.

- Processing: SLM and electron beam melting (EBM) are used for custom titanium implant parts, allowing for complex shapes that help bone grow into them.

- Biocompatibility: Titanium is the gold standard. CoCr alloys are usually safe, though they can release ions.

Esthetics: They are not tooth-colored and need a porcelain layer in areas where looks matter.

Emerging Materials and Innovations

Istar Dental Lab is always checking and using new materials and techniques:

- Hybrid Ceramics and Zirconia-Reinforced Lithium Silicate: These offer a middle ground between traditional ceramics with easier processing.

- Advanced Composite Resins: These are being developed as better alternatives to PMMA for denture bases and temporary restorations.

- Surface Modification: We look into surface treatments for PEEK to help it bond better, and for metals to help them integrate with tissue.

- Additive Manufacturing of Ceramics: Research into 3D printing zirconia and other ceramics looks very promising for custom full-arch frames. It could change how things are done in 3–5 years by lowering costs and allowing for more customization.

Our complete understanding and use of these materials, along with our advanced manufacturing skills, allow Istar Dental Lab to provide dental arch solutions that are at the leading edge of dental technology and patient care.

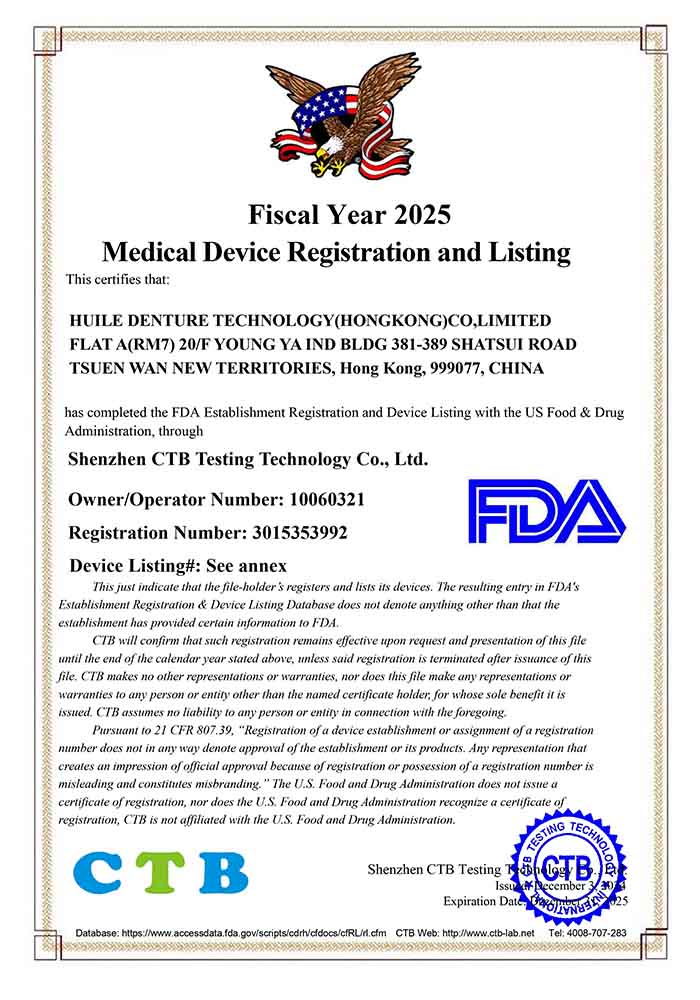

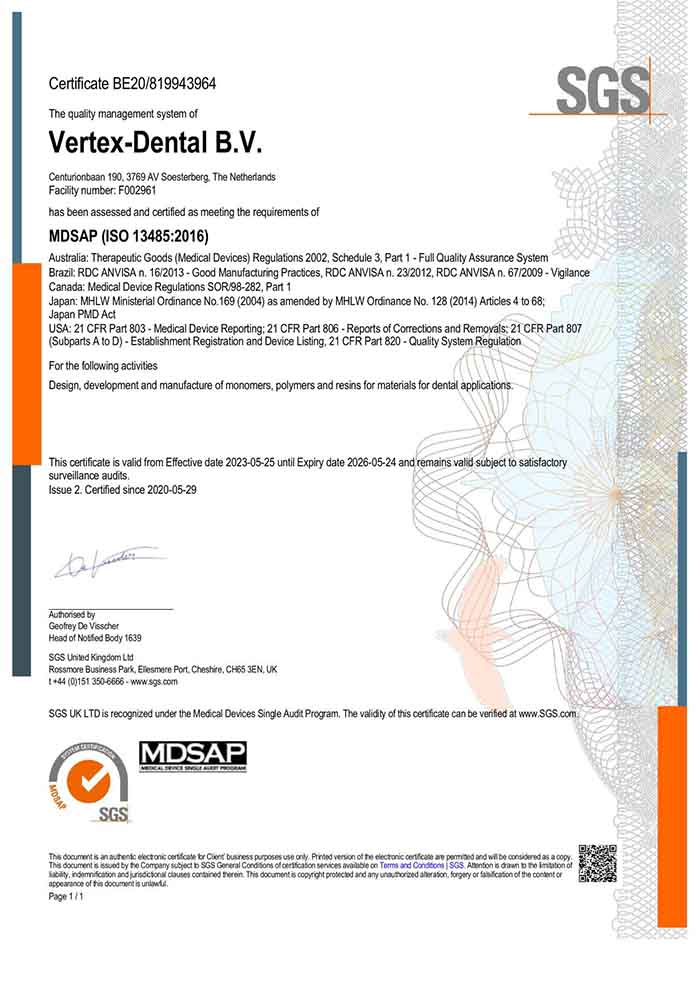

Certificates Istar Have Obtained

We’re a top-5 Arch dental laboratory in China, CE & FDA & ISO certified, NADL member. 10 years of quality restorations, implants, and dentures. Your trusted dentistry partner.

What Our Doctor’s Say

"Istar Dental Lab has been an invaluable partner in our dental practice. Their full arch restorations are of exceptional quality, and the seamless workflow makes collaboration effortless. Our patients are thrilled with their new set of teeth!"

"Working with Istar Dental Lab has elevated our restorative dentistry services. Their expertise in full-arch dental implants gives us peace of mind knowing that our patients receive the best care possible."

"The craftsmanship and attention to detail from Istar Dental Lab are outstanding. The implant-supported prostheses fit and comfortable, providing our patients with the confident smile they've always wanted."

"Istar Dental Lab's advanced dental technology and zirconia crowns have transformed our patients' smiles. The aesthetics and durability are unmatched."

"We highly recommend Istar Dental Lab for their reliable turnaround times and excellent customer service. They help us every step of the way to find the right solutions for our patients."

Experience faster turnaround times with our cutting-edge technology

Latest from Blog

Explore dentistry trends, dental lab insights, digital dentistry updates, and tips for dentists on implants, crowns, restorations, and dental technology.

How Do Dentists Help the Community? Beyond the Chair and Into Everyday Life

When most people think about dentists, they picture a bright light, a reclining chair, and someone asking questions while…

How Do You Get Rid of Numbness From the Dentist? A Real-World Guide

Walking out of the dental office with half your face asleep is… not the vibe. You’re drooling a little,…

How Do I Choose a Dentist?

Choosing a dentist isn’t like choosing a new café. You’re literally handing someone sharp instruments, your health, your money,…