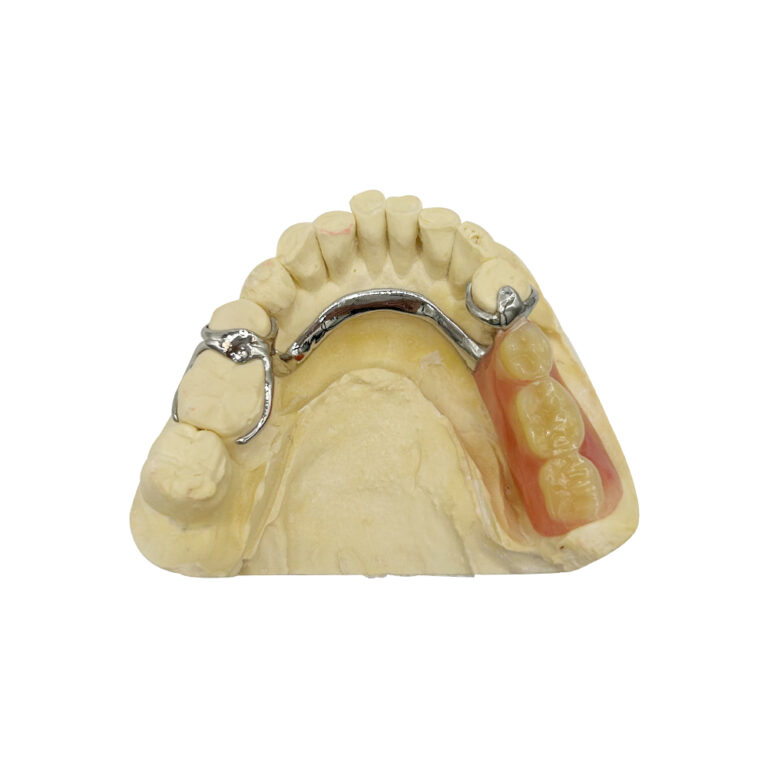

Chromium Cobalt Partial Denture, Cobalt Chrome(CoCr) Dental Plate

Chromium Cobalt Partial Dentures and Cobalt Chrome (CoCr) Dental Plates

What is a Chromium Cobalt Denture?

A Chromium Cobalt Denture is a kind of removable partial denture. It uses a strong but light cobalt-chromium metal frame. This frame holds fake teeth to fill in the gaps where you have missing teeth. The chrome cobalt partial denture is known for being very strong, comfortable, and easy to wear every day.

As Istar Dental Lab, one of the top five leading dental labs in China, we are dedicated to giving our valued partners—dentists, dental clinics, hospitals, and other dental labs around the world—the most modern and trustworthy dental replacement solutions. We are skilled in all types of dental work, especially with materials that work great and make patients happy. Among these, Cobalt-Chrome (CoCr) alloys are a key material for making removable partial dentures (RPDs) and other dental plates. They have a long history of improvement and set the standard for modern tooth replacement.

Key Features

How it Feels and Works (Mechanical, Physical, and Chemical Properties)

CoCr alloys are mostly made of cobalt (Co) and chromium (Cr). The amount of chromium is usually between 25% and 30%.

When these elements work together, they create a material with great features:

- High Strength and Stiffness: CoCr alloys are very strong and stiff. This stiffness is very important for RPD frameworks, so the frame doesn’t bend when you bite down. This is key for keeping the denture stable and protecting the teeth that hold it in place. This feature was a big reason why people first started using CoCr instead of gold, which is more flexible.

- Resists Breaking Down: CoCr is excellent at handling being used over and over again without breaking. This helps partial dentures last for a long time. This is especially important in the mouth, where dentures are always being used for chewing.

- Resists Rust and Stains: The chromium in the alloy is the main reason why CoCr doesn’t rust or break down. Chromium mixes with oxygen in the mouth to form a thin, stable, protective layer of chromium oxide ($Cr_2O_3$) on the surface. This layer acts like a shield, stopping rust and the release of metal bits. This feature was key to the long-term success of CoCr RPD frameworks and makes them different from other basic metals.

- Hardness: CoCr alloys are much harder than gold alloys. This helps them resist wear and keep their shape over time. However, this hardness means you need special tools and skills to finish and polish them.

- Lightweight: As mentioned, CoCr alloys are much lighter than gold, which makes them more comfortable for patients.

How it Interacts with Your Body (Biological Interactions and Biocompatibility)

How a material gets along with the human body is a very important thing to think about. CoCr alloys have proven to be very safe for the body, making them a secure and dependable choice for dental products.

- Protective Oxide Layer: The stable chromium oxide layer not only provides rust resistance but also stops metal bits from getting into your mouth and body. This low release of metal bits is a main reason why it gets along so well with mouth tissues.

- Low Allergy Risk: While all metals can release bits and possibly cause allergies, CoCr is generally less likely to cause allergic reactions compared to other metals, especially nickel-chromium (NiCr) alloys. Nickel is known to cause allergies, so the fact that CoCr has little to no nickel makes it a better choice for sensitive patients. Official groups, like those that follow ISO 22674 standards, always check and create rules for dental metals like CoCr to make sure they are safe and work well.

- Good Tissue Reaction: Studies and long-term use have shown good reactions from mouth tissues to CoCr frameworks, with very little swelling or bad reactions in the nearby gums and mouth lining.

How is a Chrome Cobalt Partial Denture Made?

Making CoCr dental plates has changed a lot, moving from old-fashioned methods that took a lot of work to very accurate digital methods. At Istar Dental Lab, we are experts at both, giving our partners choices and the quality that comes from our ability to do it all.

Old-Fashioned Casting Methods

The lost-wax casting process is a classic way to make CoCr frames that is still used today because it’s reliable and doesn’t cost too much. This method has several detailed steps:

- Making a Wax Shape: A wax model of the RPD frame is carefully shaped by hand on a special model. This takes a lot of skill and knowledge about mouth shapes.

- Covering the Wax: Channels are attached to the wax shape, and the whole thing is covered in a special heat-proof material, usually phosphate-bonded investments. This material is needed because CoCr alloys melt at very high heat (around 1300–1500°C) and the material must handle that heat without breaking down.

- Burning Out the Wax: The covered mold is heated in an oven to burn away the wax, which leaves a perfect empty space in the shape of the frame.

- Pouring the Metal: Melted CoCr alloy is poured or forced into the hot mold. This used to be a big challenge because of the high heat and how the metal reacts, so it requires special machines and exact temperature control.

- Cleaning and Polishing: After it cools, the metal frame is taken out of the mold, and the extra bits are cut off. The frame is then ground, finished, and polished until it has the right fit, shape, and a smooth surface. This hands-on work takes a lot of time and very skilled workers.

Using the lost-wax method with phosphate-bonded investments was a key step that helped CoCr become popular. By the 1950s and 1960s, dental companies like Dentsply and Ivoclar Vivadent started making standard CoCr alloys, which made them easier to get and improved the quality of the final product.

Modern Digital Manufacturing Methods

A big change happened with the start of digital dentistry, which has greatly changed how CoCr frames are made. At Istar Dental Lab, we have started using these new methods to make things more accurate, faster, and more consistent.

CAD/CAM Milling

This method isn’t as common for full RPD frames because of their tricky shapes, but it’s used for some CoCr parts or simpler designs.

- Digital Design (CAD): A dental model is scanned to create a 3D digital version. The RPD frame is then designed on a computer with special CAD software. This gives us total control over thickness, hold, and fit.

- Milling (CAM): The digital design is sent to a CAM milling machine, which carves the frame out of a solid block of CoCr. This way is very precise but can use up a lot of material, and the cutting tool can’t always reach some tricky shapes.

Additive Manufacturing (3D Printing) – Selective Laser Melting (SLM)

Selective Laser Melting (SLM), also known as Direct Metal Laser Sintering (DMLS), has completely changed how CoCr frames are made. This 3D printing method is now our favorite digital way to make them at Istar Dental Lab because it’s more accurate, faster, and lets us create any shape.

- Digital Design (CAD): Just like with milling, the RPD frame is designed on a computer. This lets us make very detailed designs, better clasps, and a perfect fit based on the patient’s scan.

- 3D Printing (SLM): A powerful laser melts layers of fine CoCr powder one by one, based on the digital design. Each new layer is stuck to the one before it, building the frame from the ground up.

- Finishing: After printing, the frames are taken off the build plate, heated to relieve stress, and then given a quick finish and polish.

At Istar Dental Lab, our use of the newest SLM technology for CoCr frameworks shows our dedication to making top-quality dental products. This technology, along with our skilled workers who watch over every step from digital design to the final polish, makes sure our partners get CoCr dental plates that not only look good but also work better and last much longer. We are proud to be leading the way with this new technology, offering solutions that meet the changing needs of modern dentistry.

Usage Scenarios

- When some, but not all, teeth are missing (Kennedy classes I-IV)

- To replace back teeth where you need to chew hard

- For people with a sensitive gag reflex (since the denture is thin and covers less of the mouth)

- As a long-term solution for reliable mouth function

- Used every day by dental clinics and labs for patients who want an alternative to all-plastic dentures or more comfort.

Caring for Your CoCr Denture

- Take it out at night and clean it with a brush and denture cleanser.

- Rinse it after meals to keep food from getting stuck in the clasps and frame.

- Keep it in water when you’re not wearing it so it doesn’t dry out.

- Regular check-ups with your dentist will keep your chrome cobalt partial denture working well.

Why Dental Professionals Trust CoCr Dentures

- High Strength and Stiffness: As we talked about before, the natural strength of CoCr alloys lets them handle strong and repeated biting forces without bending or breaking. This stiffness is key for keeping the frame’s shape and the denture’s stability over time.

- Excellent Fatigue Resistance: The ability of CoCr to avoid cracking under repeated use ensures that the frame stays in one piece even after years of chewing and talking.

- Superior Corrosion Resistance: The protective chromium oxide layer shields the alloy from the harsh environment of the mouth, preventing it from breaking down and keeping the frame strong. This is a key reason for the long-term success of CoCr RPD frameworks.

- Stays in Shape: CoCr frameworks keep their exact fit over time. This means fewer trips to the dentist for adjustments, which helps them last longer.

Who Should Order From Us?

- Dentists who care about strength and patient comfort

- Dental hospitals that need reliable results for many patients

- Dental clinics that offer top-quality replacement teeth

- Dental labs that want materials that work with both new digital and old-fashioned methods

Conclusion

CoCr alloys are still the top choice for most RPD frameworks because they have a great mix of strength, safety for the body, can be made in different ways, and are a good value for the cost. At Istar Dental Lab, we understand these materials inside and out, which allows us to help our partners choose the best solution for each patient, ensuring the best results and long-term happiness.

Contact us today to find out how our chrome cobalt partial denture solutions can help you.