Dental Plates For Adults

A Top Lab for Dental Plates For Adults

As Istar Dental Lab, a well-known leader around the world and one of the top five dental laboratories in China, we help our partners—dentists, dental clinics, hospitals, and other dental labs worldwide—by providing the latest, high-quality dental plates for adults. Our focus on quality comes from a solid understanding of prosthodontic science, modern production methods, and achieving results that focus on the patient.

A Full Range of Denture Options

Correctly classifying and carefully designing adult dental plates is very important for them to work well, ensuring they fit perfectly, work correctly, and are comfortable for the patient. At Istar Dental Lab, we are experts in all types of removable prostheses, made to fit each patient’s specific needs and mouth shape.

We offer a wide range of Types of dental prostheses to meet every patient’s unique needs and budget. Our goal is to help your clinic offer flexible and good solutions for Missing teeth replacement. Our offerings for [[dental plates for adults]] are designed to help with everything from a few missing teeth to a complete loss of teeth (Edentulism).

Complete Dentures: Full Arch Rehabilitation

Complete dentures are for patients who have lost all their natural teeth in a jaw. Our design approach for complete dentures focuses on getting three key things right:

- Support: We get this by extending the denture base to cover as much of the gum and bone as possible. This spreads out the chewing pressure evenly, which reduces sore spots.

- Retention: This is mainly done with a border seal that creates a natural suction. The precise shape of the denture edge helps create a vacuum effect to keep it from coming loose.

- Stability: We make sure of this by perfecting the base, the edge design, and the bite to stand up to side-to-side and twisting forces during chewing and talking. The denture base (usually made from acrylic resin) and artificial teeth (acrylic or porcelain) are the main parts. The part that covers the roof of the mouth in upper dentures and the right edge shape in both jaws are very important for a great hold and a steady fit.

Removable Partial Dentures (RPDs): Solutions for a Few Missing Teeth

Removable partial dentures are used when one or more natural teeth are still in the jaw to act as anchors for the new teeth. Designing RPDs is naturally more complicated and needs a careful balance of hold, support, and steadiness, which is usually done with a custom-made metal frame.

Our RPDs usually include:

- Metal Framework: Usually made from cobalt-chromium (Co-Cr) alloy, which makes it strong, stiff, and fit just right.

- Major and Minor Connectors: Major connectors (like a palatal strap or lingual bar) keep the denture stable across the whole jaw and spread out forces. Minor connectors link the frame to other parts.

- Rests: Placed on the anchor teeth, rests stop the RPD from moving up and down and guide chewing pressure down the length of the anchor teeth so they don’t get too much stress.

- Direct and Indirect Retainers (Clasps): Clasps grip the natural curves of the anchor teeth to hold the denture in place. Indirect retainers stop the RPD from rocking or twisting, especially in cases where teeth are missing at the back.

- Denture Base with Artificial Teeth: The denture base, which is often acrylic, holds the new teeth and covers the area where teeth are missing.

The type of clasp (like a circumferential or I-bar) and major connector is carefully chosen based on the shape of the jaw and the Kennedy Classification system, which groups different types of missing teeth patterns:

- Class I (Bilateral Free-End): Missing teeth on both sides at the back of the mouth. This needs careful design to handle twisting forces.

- Class II (Unilateral Free-End): Missing teeth on one side at the back of the mouth. This is similar to Class I, but only on one side.

- Class III (Bounded Edentulous Space): A gap with natural teeth in front of and behind it. This allows for very strong support.

- Class IV (Anterior Bounded Edentulous Space): A single gap of missing teeth at the front of the mouth that crosses the middle.

This classification system helps us design the RPD for the best possible performance and function.

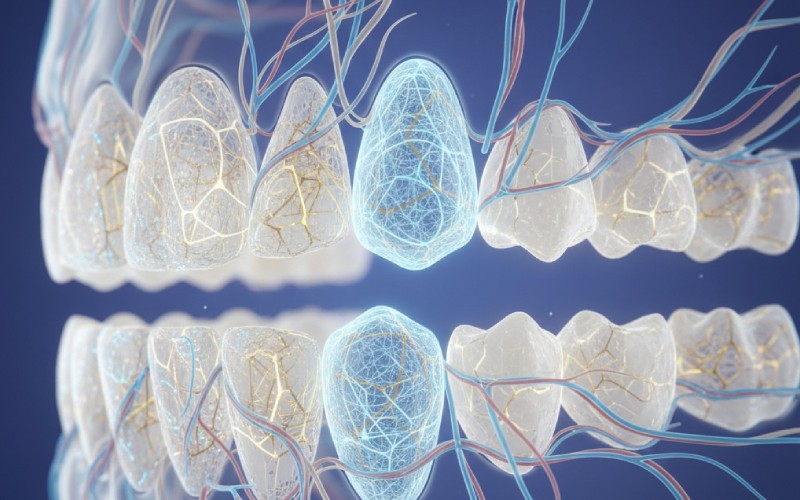

Advanced Materials of Adult Dental Plates

Choosing and using the right materials is key to the high quality and performance of the removable dental prostheses made by Istar Dental Lab. Our knowledge of materials makes sure that every denture we make meets the highest standards for strength, safety, long life, and patient comfort.

Polymethyl Methacrylate (PMMA): The Classic Standard

PMMA is still the most popular material for denture bases because it looks good, is easy to work with, and is affordable. At Istar Dental Lab, we use top-quality types of PMMA that offer:

- Flexural Strength: Strong enough for daily use.

- Impact Resistance: Our making process helps it resist breaking from chewing or being dropped.

- Dimensional Stability: It holds its shape well over time for a long-lasting fit.

We know all about the concerns with leftover monomer, which can cause irritation or allergic reactions in a small number of patients. Our advanced making process greatly reduces this leftover material, lowering this risk.

Cobalt-Chromium (Co-Cr) Alloys: Strength and Precision for RPD Frameworks

Co-Cr alloys are our top choice for the frames of removable partial dentures because they have amazing strength:

- High Flexural Strength: Very stiff and won’t bend or change shape.

- Excellent Fatigue Resistance: It stays strong for a long time, even with constant chewing.

- Low Density: This makes it lightweight and more comfortable for the patient.

While Co-Cr alloys are very safe, we are careful about potential nickel content in some types. Our quality control makes sure we use nickel-free or very low-nickel alloys to avoid problems.

PEEK (Polyetheretherketone): The New High-Performance Polymer

PEEK is quickly becoming popular for denture bases and frames, especially for patients with metal allergies or who want something lighter and more flexible. Istar Dental Lab is a leader in using PEEK because it has:

- High Flexural Strength: Very durable and long-lasting.

- Low Density (1.3 g/cm³): Makes the denture more comfortable.

- Excellent Chemical Resistance: Lasts a long time in the mouth.

- Radiolucency and Metal-Free Composition: Good for X-rays and for patients with metal sensitivities.

- Low Water Absorption (<0.1%): Helps it keep its shape perfectly.

Even though PEEK costs more and needs special ways to attach the teeth, its benefits make it a great choice for top-of-the-line solutions.

Polyamide (Nylon) Denture Bases: Flexibility and Looks

Polyamide-based flexible dentures are more comfortable and look better, especially for partial dentures where you don’t want the clasps to show. We like their benefits, including:

- Enhanced Comfort: Due to their natural flexibility.

- Superior Aesthetics: They are often see-through and blend in perfectly with the natural gums.

However, we also know their limits, like having less strength and a tendency to bend out of shape for good under heavy chewing. Our designs take these features into account to make sure they are used in the right situations.

Advanced Surface Treatments and Coatings

To make our products work even better and last longer, Istar Dental Lab uses special surface treatments and coatings. Recent research (2023–2024) has shown that these methods can:

- Reduce Microbial Adhesion: Stop germs from sticking, which lowers the chance of mouth sores (denture stomatitis) and keeps the mouth cleaner.

- Improve Wear Resistance: Makes the denture last longer.

We build these new ideas into our making processes because we care about our patients’ health.

Advanced Manufacturing Technologies for Adult Dental Plates

Istar Dental Lab is a leader in digital dentistry, using modern production methods to make removable dental prostheses with amazing accuracy, speed, and consistency. Our digital process changes the old way of making dentures, giving great benefits to our partners all over the world.

End-to-End Digital Workflow Adoption

Our modern process for removable dentures starts with digital scanning, getting rid of the need for messy physical molds. We easily combine data from top intraoral scanners like 3Shape TRIOS, Medit i700, and Carestream CS 3800. This digital data is the start of our fast process, going directly into advanced design software.

CAD Design Innovations

Our design team uses top design software, including exocad DentalCAD and 3Shape Dental System, which can design a full set of teeth and the base. This software has large libraries of tooth shapes and bite styles, letting us create highly custom and accurate designs.

A special feature that sets us apart is that we use AI to help with the design. Using AI tools in exocad and 3Shape, we can automatically set up the teeth and improve the look and function based on the patient’s data. This not only makes designing faster but also gives more predictable results.

CAM and 3D Printing Modalities

To physically make the dentures, Istar Dental Lab uses the most advanced 3D printing methods:

- Stereolithography (SLA) and Digital Light Processing (DLP): These are our main 3D printing methods for making the final dentures. We use top systems from companies like Carbon, Asiga, and Formlabs, which are known for being very accurate.

- Material Jetting: While not as common for final dentures yet, we use technologies like the Stratasys J5 DentaJet to make full-color, multi-material try-in models. This really helps the patient see what it will look like before treatment.

Enhanced Efficiency and Cost-Effectiveness

The digital process at Istar Dental Lab makes things much faster and better:

- Reduced Patient Visits: The total time can be cut from 4–5 patient visits to just 2–3 visits, saving time in the dentist’s chair.

- Rapid Turnaround: We can make a single denture in as little as 24–48 hours, so patients can finish their treatment faster.

- Cost Savings: While the upfront cost for digital equipment is high, our large-scale production and lower labor costs mean we can offer good prices, making high-quality digital dentures more affordable.

A Seamless Partnership Workflow

Our process is made to be clear, fast, and give the best results. We want to make the denture timeline easier for your practice.

- Consult & Plan: You talk to the patient about dentures and send us the case with digital scans or old-fashioned molds.

- Design & Fabrication: Our technicians design the Dental prosthetics and start making them.

- Trial & Fitting: We send a trial version for you to check the Denture fitting with your patient.

- Final Adjustments & Finish: We complete the final denture, making sure we fix any possible Denture problems like Ill-fitting dentures.

- Ongoing Support: We offer great support for Denture adjustments, Denture relining (Hard reline and Soft reline), and Denture rebase services. We also provide Emergency denture repair, including Broken denture repair and Cracked denture repair.