E.max Press vs. Mill: A Deep Dive into the Marginal Fit and Fracture of Lithium Disilicate Ceramic Crowns

I’ve been in this business a long time, and I’ve seen technologies come and go. But the debate between pressed and milled ceramic crowns is one that sticks around. Why? Because it gets to the very heart of what we do: creating restorations that fit perfectly and last for years. We’re all chasing that perfect marginal adaptation and want to avoid any chance of fracture. This article is for you if you’ve ever wondered which method, E.max Press or a CAD/CAM mill system, really delivers the best lithium disilicate ceramic crowns. We’ll dig into the vitro study evidence, look at the evaluation of marginal fit, and I’ll share my own experiences to give you a clear, simple answer. This is about making the best choice for your patients and your practice.

Table of Contents

What Is Lithium Disilicate and Why Is It So Popular?

Let’s start with the basics. When we talk about all-ceramic crowns, one material stands out: lithium disilicate glass-ceramic. You probably know it by the brand name IPS e.max from Ivoclar Vivadent. This ceramic material is a mix of glass and tiny lithium disilicate crystals. This combination gives it two things we love: it looks great, and it’s strong.

For years, we had to choose between strength and beauty. Metal-ceramic crowns were strong but didn’t always look natural. Early all-ceramic options looked good but had a risk of fracture. Lithium disilicate ceramic changed the game. It gave us a ceramic material with high fracture resistance that could be used for single crowns in both the anterior and posterior parts of the mouth. It’s a reliable choice for fixed dental prostheses and offers excellent mechanical properties. The success of this material is why the debate over how to make crowns fabricated from it—to press or to mill—is so important.

How Are E.max Press Crowns Actually Made?

The press technique feels like true craftsmanship to me. It’s an advanced version of the classic lost wax technique that dentists have used for decades to make metal crowns. First, a technician creates a waxed crown model. This model is then placed in a mold. The wax is melted out, leaving a perfect empty space in the shape of the crown.

This is where the magic happens. A small pellet of IPS e.max Press lithium disilicate glass ceramics is heated until it becomes like thick honey. Then, it’s pressed into the mold under high pressure. This process forces the material into every tiny detail of the mold. The result is a monolithic crown that is very dense and uniform. After it cools, the crown is finished and glazed. This press technique is known for creating crowns produced with amazing marginal adaptation. Many believe these pressed crowns offer the best marginal fit.

How Does a CAD/CAM System Mill a Crown?

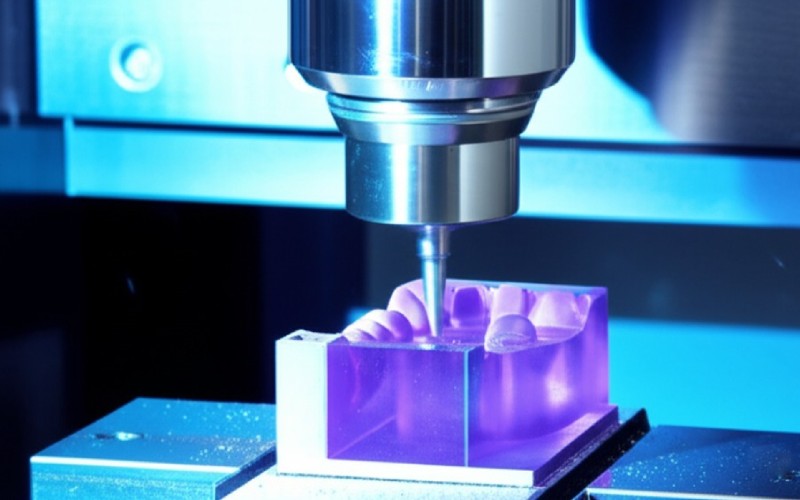

Now, let’s talk about the high-tech way: CAD/CAM. The term stands for Computer-Aided Design and Computer-Aided Manufacturing. Instead of a wax model, we start with a digital scan of the tooth. This can be done with an intraoral scanner or by scanning a physical model from conventional impressions. A technician then uses special software for the crown design. Once the design is perfect, it’s sent to a milling machine.

The milling machine is the star of the show. It takes a solid block of lithium disilicate ceramic, often IPS e.max CAD, and carves the crown out of it. It’s like a robot sculptor. The crowns were milled using diamond burs that carefully grind away the block until only the crown is left. This CAD/CAM process is fast. You can mill a monolithic crown in your office in a single visit. The question many people ask is whether a crown that a machine has to mill can have the same precise marginal edge as a pressed one. We must evaluate if the mill process can cause issues.

What Is a Marginal Gap, and Why Should We Care?

I can’t stress this enough: the marginal gap is everything. Imagine a perfect crown, but it leaves a tiny shelf or space where it meets the tooth. That space is the marginal gap. We measure this gap in micrometers, or μm. A micrometer is one-thousandth of a millimeter. It’s tiny! But even a tiny gap can cause big problems.

A large marginal gap allows bacteria and plaque to hide. This can lead to decay under the crown. It also exposes the cement, or luting agents, that we use to glue the crown on. Over time, the cement can wash out, causing the crown to fail. A good marginal fit means a very small marginal gap. This is what we mean by marginal adaptation. A good crown adaptation is the number one goal for long-term success, as it prevents fracture and failure. The evaluation of marginal and internal fit is a critical step to evaluate any crown. We are always trying to get the best marginal seal possible. This marginal issue is key.

Which Gives a Better Marginal Fit: Pressed or Milled Crowns?

This is the million-dollar question. For years, the common belief was that e.max press crowns offered a better, more consistent marginal fit. The logic was that pressing a liquid-like material into a mold would create a more passive and exact fit than a mill could achieve by grinding a block. Many early vitro study reports seemed to support this. A systematic review of studies often found that the mean marginal gap for pressed all-ceramic crowns was smaller.

However, CAD/CAM technology has gotten much, much better. Modern milling machines are incredibly precise. The software used for crown design is also more advanced. Today, many vitro study papers show that crowns fabricated with CAD/CAM can achieve a marginal fit that is just as good as pressed crowns. A study by Seyyedan et al. found very little difference. Another vitro study published in BMC Oral Health showed that while pressed crowns showed better results sometimes, the CAD/CAM crowns were well within the clinically acceptable range for a good marginal fit. The marginal fit of lithium disilicate crowns is a hot topic. We need to evaluate the marginal and internal fit of LD crowns from both methods. The marginal edge is the focus.

What About Fracture Resistance? Is a Milled Crown Weaker?

Strength is the other big piece of the puzzle. A crown with a perfect marginal seal is useless if it is likely to fracture. The lithium disilicate ceramic material itself has a high fracture resistance. The question is whether the way we make the crown affects that strength. Here, the press technique has a natural advantage. Pressing creates a very dense monolithic crown with few internal flaws.

When you mill a crown, the grinding process can create tiny micro-cracks on the surfaces of the crowns. These can become weak points where a fracture might start. This is a real concern, and it’s why the finishing steps for milled crowns are so important. After the mill is done, the crown must be carefully polished and then put through a crystallization firing process. This process not only hardens the IPS e.max CAD material but also helps to “heal” some of those surface flaws. A well-finished milled crown can have excellent mechanical properties and fracture resistance. The fracture resistance of lithium disilicate is high, but we must not introduce flaws during the mill process that could lead to fracture. A fracture is a failure.

What Do the Vitro Study Papers Really Tell Us?

When I need answers, I turn to the science. There are hundreds of vitro study papers on this topic. A vitro study means the test was done in a lab, not in a patient’s mouth. Scientists evaluate things like the marginal gap using tools like a scanning electron microscopy or a replica technique. They also do tests to measure fracture strength. What does all this research, like reports from BMC Oral Health or work by researchers like Anusavice et al., tell us?

Most studies, including a systematic review, conclude that both crowns fabricated by using the press and the CAD/CAM mill methods can produce clinically excellent dental crowns. Some studies, like one by Guess et al., might show a slight statistical advantage for the e.max press in marginal fit. For example, they might find a mean marginal gap of 60 μm for pressed vs. 75 μm for milled crowns. Both are excellent values! The null hypotheses in many studies, which assume there is no difference, are often not rejected. So, while we can compare the marginal gaps, the differences are often not large enough to matter in a real mouth. We need to evaluate the marginal and internal gaps.

How Much Does the CAD/CAM Milling Machine Matter?

This is a point that gets lost sometimes. Not all CAD/CAM systems are the same. The quality of the scanner, the sophistication of the design software, and the precision of the mill itself all play a huge role in the final marginal fit and internal fit of LD crowns. A brand-new, high-end 5-axis mill will produce a better marginal edge than an older, 3-axis machine.

The settings used by the operator also matter. Things like the size of the bur, the milling speed, and the parameters set in the software can change the marginal accuracy. This is why you can see different results from different labs, even if they both use a CAD/CAM mill. It’s not just about mill vs. press; it’s about the quality of the entire CAD/CAM workflow. A good CAD/CAM system is crucial for a good marginal adaptation and fatigue behavior. The way you mill a crown affects its marginal quality.

Does the Cement Choice Affect the Marginal Seal?

Yes, absolutely. The crown is only one part of the equation. The luting agent, or cement, is what fills the marginal gap and bonds the crown restorations to the tooth. For lithium disilicate glass-ceramic e.max crowns, we almost always use adhesive bonding. This involves etching the inside of the crown with hydrofluoric acid and using a silane coupling agent and a resin cement.

This process creates a very strong bond strength between the crown and the tooth. A strong bond helps support the ceramic material and reduces the risk of fracture. It also seals the marginal gap, protecting the tooth from bacteria. So, even if there is a small marginal gap (and there always is), a good bonding protocol can make it a non-issue. The marginal fit and internal fit are important, but the final seal depends on good cementation. The marginal adaptation and fracture resistance are linked to this final step.

My Final Take: When to Press and When to Mill?

After looking at all the evidence and relying on my own experience, here is my conclusion. For the absolute best, most consistent marginal adaptation, especially for a tricky case in the front of the mouth, I still have a soft spot for IPS e.max Press. The press technique just seems to produce a beautiful, passive fit. The marginal edges are often flawless.

However, modern CAD/CAM technology is amazing. For posterior fixed dental prostheses or a monolithic crown where speed is a factor, a mill is a fantastic choice. The survival and complication rates for lithium-disilicate crowns made with a quality CAD/CAM system are excellent. You can mill a crown with a marginal fit that is easily within the best clinical standards. The key is to evaluate your CAD/CAM system and have great finishing protocols to avoid fracture. Ultimately, both crowns were fabricated to do the same job. The choice between two distinct fabrication methods often comes down to the specific clinical situation and the tools you have. There’s no single wrong answer, only what’s best for that tooth, that day.

Key Takeaways to Remember:

- Both Are Great: Both

E.max Pressand modernCAD/CAMmillsystems can create excellentlithium disilicate ceramic crownswith a goodmarginal fit. - Fit vs. Speed: Traditionally, pressed crowns were known for a slightly better

marginal fit, whilemilled crownsoffer incredible speed and convenience. - Technology Matters: The quality of the

CAD/CAMmilland software is a huge factor. A high-endmillcan produce results as good as the press technique. - Finishing is Crucial: For

milled crowns, proper polishing and firing are essential to reduce the risk offractureand improve strength. - Don’t Forget Cement: The final

marginalseal andfractureresistance depend heavily on using the rightluting agentsand bonding protocol. - Evaluate Each Case: The best choice between press and

millmay change depending on the tooth, the patient’s needs, and your lab’s capabilities.