Flexible Horseshoe Dentures

Your Top Flexible Horseshoe Dentures Manufacturer

Istar Dental Lab is a top denture maker that works with dentists all over the world. We offer high-quality lab services to dental hospitals, dental labs, and dental clinics of all sizes.

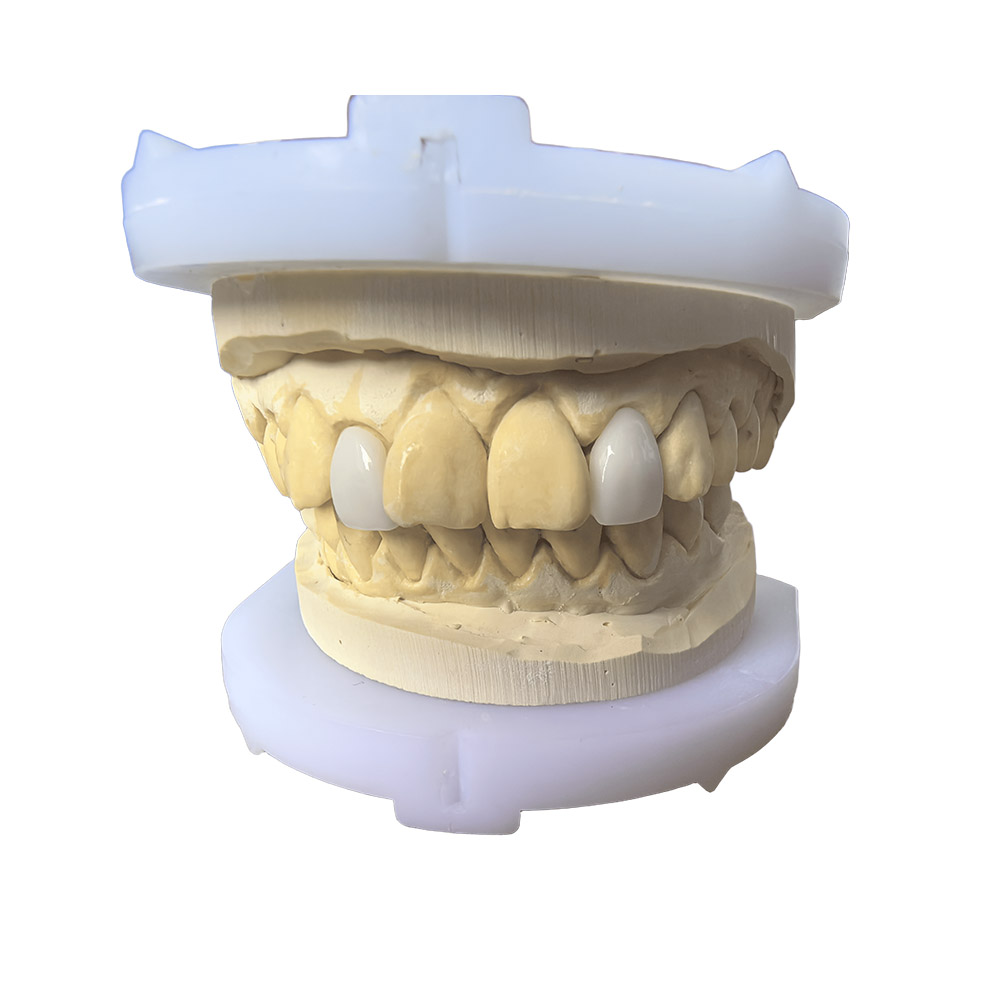

Our specialty is making the best flexible horseshoe dentures. A flexible horseshoe denture is a type of removable partial (or sometimes, complete) dental replacement known for its special U-shape (like a horseshoe). This design is used for upper teeth to avoid covering the roof of the mouth (making it “palateless”). For lower teeth, it’s often shaped like a lingual bar to be less bulky and more comfortable for the patient by following the inside curve of the jaw and teeth.

What makes these replacements special is that they are made from flexible, plastic-like, non-metal materials. Unlike regular hard acrylic or metal-based dentures, these materials give them some flexibility, make them more comfortable, and provide a better look. They are a good choice for a removable partial denture, especially in cases where regular, stiff frames aren’t the best fit or the patient doesn’t want them.

The Clear Advantage: Why Work With Us?

We focus on making things better for your patients and your dental office. We like to be clear about how our products help.

For Your Patients: A New Level of Comfort and Confidence

- No More Gagging: Our horseshoe upper dentures have a special palateless upper denture design. This roofless upper denture style means nothing covers the top of the mouth. This is a big plus for any patient who gags easily.

- A Natural Feel: We make amazing ultra thin horseshoe dentures. These lightweight dentures are so comfortable. Patients can enjoy the real taste and temperature of their food again.

- A Beautiful Smile: Our aesthetic partial dentures are made to look real. They use a flexible partial with clear clasps that blend in. There are no metal parts to be seen. This helps in making smiles look better.

- Safe and Gentle: Our products are hypoallergenic dentures. They are metal-free partial dentures made from materials that are safe for the body. This is great for people with allergies. The design helps stop gum soreness and allows gthe ums to get used to the denture.

For Your Practice: Quality, Speed, and Support

- Top-Quality Products: We use the best flexible denture materials to make long-lasting flexible dentures. Our process makes sure they fit perfectly every time, helping patients chew better and speak more clearly with their dentures.

- Easy Ordering: Send us your case with digital scans or old-school dental molds. We work with you to get a correct bite measurement for the best results.

- Expert Help: Our team of skilled Dental Technicians is here to help. We offer support for in-office denture adjustments and chairside denture adjustments.

Materials Science of Flexible Resins

How well flexible horseshoe dentures work is directly tied to the specific thermoplastic resins used to make them. These materials are chosen for their special physical and mechanical qualities that make them different from regular denture base acrylics (PMMA).

The main materials are polyamides (nylons), like those in products such as Valplast®, Flexite®, and Lucitone® FRS. Other materials are polyacetals (polyoxymethylene), sometimes used for clasps or stiffer parts (e.g., Acetal Resin, Dental D). We are also using more advanced thermoplastic elastomers (TPEs) and polymer mixes (e.g., PEEK composites, new polyamide mixes from companies like Evonik and Mitsui Chemicals).

New materials coming out include germ-killing and body-friendly additives (like silver nanoparticles, zinc oxide, quaternary ammonium compounds). These are being added to resins to lower the build-up of germs and reduce yeast infections, and recent studies (2023) show they work well.

Design Principles and Configurations

The design of flexible horseshoe dentures is very different from regular stiff partial dentures. This is mainly because of the material’s natural flexibility and the goal of covering less of the roof or floor of the mouth.

Key design ideas include:

- No Stiff Main Connectors: The key feature is that we leave out stiff main connectors like full roof plates or large plates on the floor of the mouth. On the top, this gives you the palateless horseshoe design, leaving the roof of the mouth open. On the bottom, it’s often a lingual bar, a thin connector that follows the inside curve. This choice makes patients more comfortable, helps with speech and taste, but completely changes how the denture works mechanically.

- Flexible Clasp Design: The grip comes mostly from flexible clasps made of the same material as the base. These clasps are designed to fit into deeper grooves (up to 0.5 mm or more) than regular metal clasps. Their flexibility lets them slip over bumps and into grooves easily, holding on by locking in place rather than by a stiff grip. Common designs are wrap-around and I-bar shapes. Studies (e.g., 2022, Journal of Prosthodontics) show that wrap-around clasps look better and are more comfortable but might not hold as predictably as cast metal clasps.

- No Rests: Flexible partials usually don’t have rests that sit on the chewing surfaces of teeth. This is because the material is flexible; a flexible rest would bend under chewing pressure and wouldn’t properly transfer force to the supporting tooth. Without rests, the denture is supported almost entirely by the gums, making it a “tissue-borne” device.

- Minimal Minor Connectors: The small parts that connect clasps to the denture base are very small or built right into the base in flexible designs. They don’t provide much support or spread out stress like they do in stiff frames.

- How it Stays In: The grip depends a lot on having natural tooth grooves and how deep they are. The flexible material bends to pop into these grooves when putting the denture in or taking it out. How well it works can change and may be a problem if grooves are shallow or teeth are shaped poorly.

- Mechanical Trade-offs: Not having stiff connectors and rests leads to big trade-offs. The denture can move around during use, which can spread pressure unevenly on the gums and supporting teeth. This raises the risk of gum irritation and faster bone loss, especially for long gaps or back teeth replacements (Kennedy Class I and II).

- Clasp Design Factors: How well flexible clasps work is affected by things like their thickness (usually 1.0–1.5 mm), length, and the angle they use to enter the groove.

While the design focuses on comfort and looks, the mechanical downsides mean you have to pick cases carefully. Flexible horseshoe and lingual bar partials are best for filling gaps between teeth (Kennedy Class III) where the gums are in good shape and there are good grooves, or as temporary dentures. They are usually not a good idea for cases with many missing teeth or where strong support is needed.

Manufacturing Processes

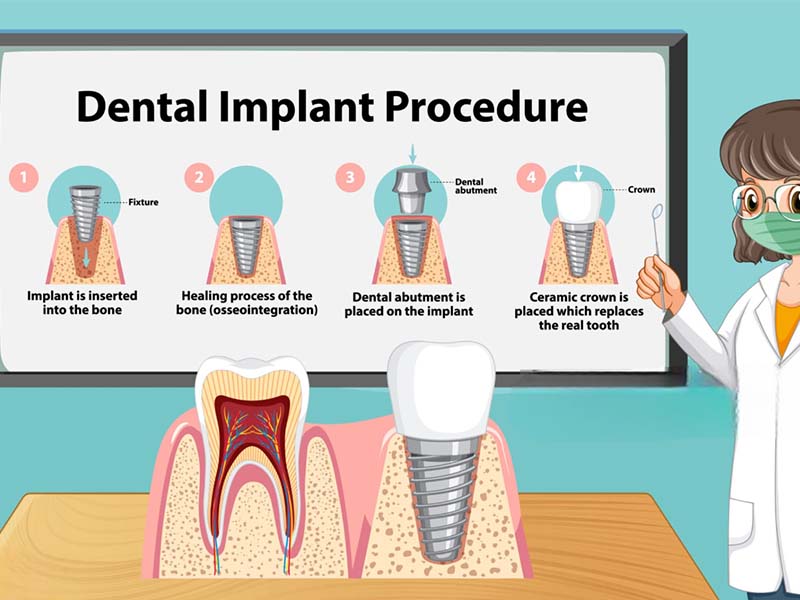

Making flexible horseshoe dentures mainly uses injection molding. This process is specially set up for thermoplastic resins. This method makes sure the final product is an exact copy of the mold and takes advantage of what makes these materials special.

The usual way we make them at Istar Dental Lab involves several careful steps:

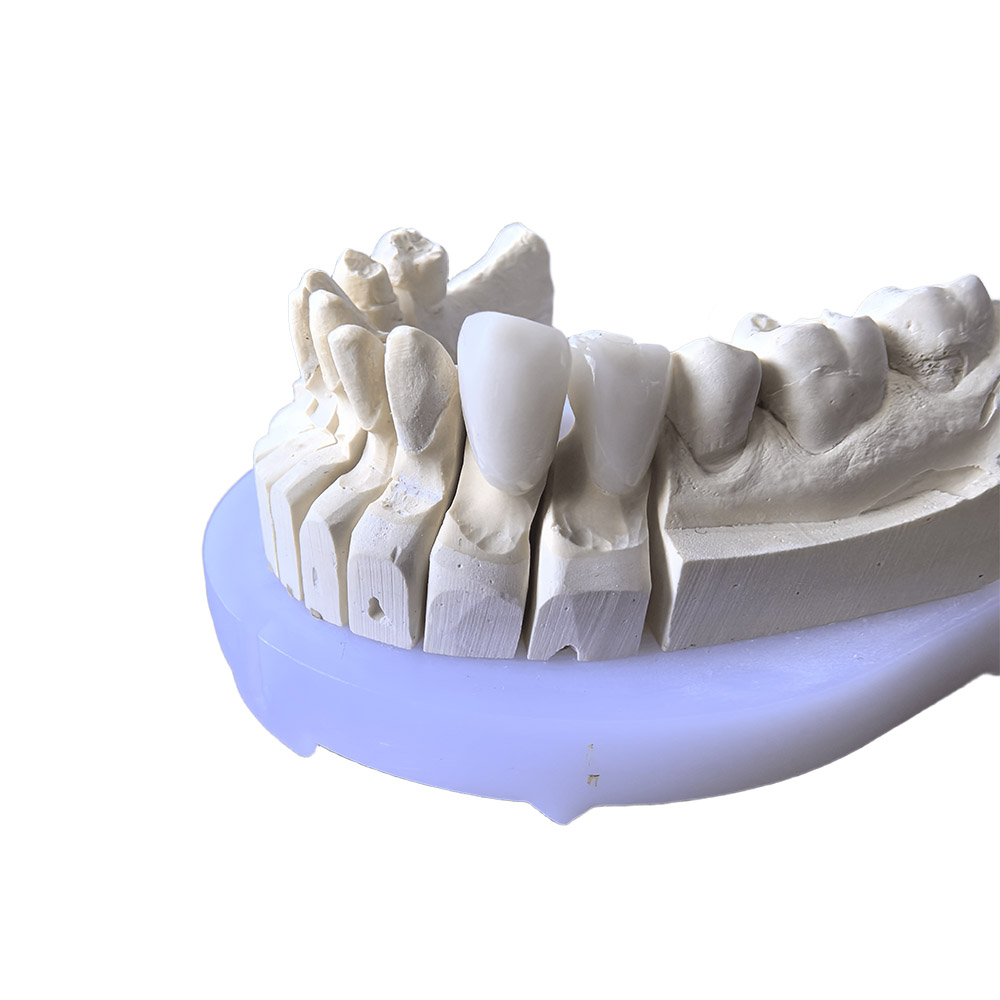

- Wax-Up: We make a normal wax model of the denture base and clasps on a master model. It shows the exact shape we want and uses the planned grooves.

- Flasking: The wax model is put into a special metal or strong polymer box. These boxes, like the ones used in the Valplast Injection System or FlexPress II, are built to handle the high pressure and heat of injection molding and have locks to stop leaks. We usually use a two-step pour with dental stone or a similar material.

- Wax Removal: After the material hardens, the box is opened, and the wax is melted out with boiling water, leaving a perfect mold space.

- Resin Prep and Preheating: The thermoplastic resin comes in tubes or small pellets. We preheat them in a special furnace or heater. For polyamide resins, temperatures are usually between 220°C and 280°C. They stay in for 10–20 minutes to make sure the resin is fully melted and mixed, which stops holes or incomplete fills.

- Injection Molding: The hot, melted resin tube is put into the injection machine. The machine uses pressure, usually between 6–8 bar (87–116 psi) for polyamide systems, to push the resin into the mold. This takes 30 seconds to 2 minutes, depending on the machine and the size of the denture. Keeping the temperature just right (±2°C) is very important to stop the resin from hardening too early or being damaged by heat.

- Cooling: After injecting, the box is left to cool down slowly, either at room temperature or in a controlled water bath, for 10–20 minutes. Cooling too fast can cause stress and warping.

- Demolding: Once it’s cool enough, we carefully open the box and take out the flexible denture, being careful not to bend it.

- Finishing and Polishing: Extra bits are trimmed off with fine carbide or diamond tools. Polishing needs special pastes made for these plastics, as normal acrylic polishes can make the surface cloudy or cause tiny cracks. We get the final shine with soft cloth wheels and very little pressure to avoid overheating.

- Quality Checks: During the whole process, we do quality checks like looking for holes, incomplete fills, and surface problems. Some high-tech labs might use tests like dye penetration or micro-CT. We check the size against the master model to make sure it’s accurate.

- Common Making Problems: Holes (from moisture or not enough pressure), incomplete fills (from cooling too fast or poor flow), and warping (from uneven cooling or a crooked box) are common issues that need a skilled person to avoid.

- Comparison with Metal Frame Casting: Injection molding gets rid of the need for high-heat furnaces and burnout ovens used for casting metal frames (like cobalt-chromium). This reduces workplace dangers and makes the process simpler. However, it needs special, brand-specific injection systems and supplies.

- New Technology: Digital methods that mix CAD/CAM design with injection molding are starting to appear, giving us better control over fit and thickness. Mixed systems that use 3D-printed molds with injected plastics are also being tested to make production even smoother.

- Environmental Thoughts: While injection molding uses more energy per item than PMMA compression molding, it can be faster and create less waste. We need to think about how to dispose of the plastic waste, and some companies are working on plant-based or recyclable resins.

Clinical Applications, Advantages, and Limitations

Flexible horseshoe dentures can be used in a special set of clinical situations, but they have big pros and cons that must be thought about carefully when planning treatment.

When to Use Them (Clinical Indications):

- When Looks Matter: A great choice for patients who care a lot about looks, especially for the upper front teeth, because the see-through, gum-colored base and clasps blend in perfectly with the mouth.

- Metal-Free Choice/Allergy: A perfect option for patients who are allergic to dental metals or acrylic monomers (MMA), or for those who just don’t like the idea of having metal in their mouth.

- Tricky Anatomy: Useful in cases with large soft tissue or bone grooves (like tori, exostoses, or bumpy gums) where stiff frames would need a lot of blocking out or even surgery. The material’s flexibility lets it fit into these grooves easily.

- Temporary or Transitional Dentures: Often used as temporary dentures after teeth are pulled or while implants are healing because they can be made quickly, are adaptable, and comfortable.

- Few Missing Teeth: Best for filling gaps between teeth (Kennedy Class III) where there is good support from other teeth and the gum shape is good.

Advantages:

- Better Looks: They look much better because there are no visible metal clasps and the base color can match the gums.

- More Comfortable for Patients: They are light, thin (often 1.0–1.5 mm thick in the horseshoe part), and flexible. This means patients get used to them quickly, they feel less bulky, and cause fewer sore spots than regular acrylic dentures.

- Very Little Tooth Prep: The grip comes from flexible clasps fitting into natural grooves, so little to no tooth filing is needed, which saves tooth structure.

- Gentle Grip: Flexible clasps fit into grooves gently, putting less stress on supporting teeth when putting the denture in and taking it out.

- Hypoallergenic: Usually free of MMA, which lowers the risk of allergic reactions that are common with regular acrylics.

Limitations:

- Lack of Direct Support: The main downside is that there are no stiff rests, so they are mainly supported by the gums. This can lead to them being unstable and moving during chewing, especially for long gaps or back teeth replacements (Kennedy Class I and II).

- Functional Instability: The flexibility can make them less stable, especially with uneven gums or heavy chewing, which can affect how well a person can chew.

- Hard to Reline and Repair: Polyamide-based materials are hard to reline or fix because they don’t stick well to regular acrylics and repair materials. This often means the whole denture has to be remade, which costs more and is less convenient in the long run.

- Hard to Adjust: Making adjustments in the office is harder than with acrylic or metal. You need special tools and methods to avoid damaging the material’s surface.

- Potential for Gum Pinching: The close fit and flexibility can lead to pinching the gums if the base is too long or if the gum line shrinks a lot without a reline.

- Hygiene Problems: Some flexible materials can have more tiny holes than regular acrylic, which can trap germs and raise the risk of yeast infections and bad breath if not cleaned perfectly. It’s very important that patients clean them well. Not doing so is linked to more plaque, gum inflammation, and mouth sores (in some studies, up to 25% of people who wore them for over 3 years had these issues).

- Long-Term Bending: Flexible materials can slowly bend and lose their shape over time, which can make them fit poorly and not hold as well.

- Color Stability: They can get stained and change color over time more easily than other, more stable materials.

When NOT to Use Them (Contraindications):

- Many Missing Teeth: Not recommended for long gaps at the back (Kennedy Class I and II) because they lack stiff support and can cause the gum line to shrink faster.

- Poor Gum Support: Not for patients with weak gum support or loose supporting teeth, as the flexible base can put too much force on the gums and bone.

- Severe Gum Shrinkage: Not as effective in cases with very shrunken or flat gums because there isn’t enough tissue support.

- Deep Bites: Patients with deep bites might put too much force on the flexible base, causing it to bend or hurt the gums.

- Need for a Precise Bite: The natural flexibility makes it hard to get a very precise bite and keep it stable.

Comparison with Conventional Rigid Partial Dentures

A side-by-side look at flexible horseshoe dentures and regular stiff partial dentures (acrylic or cast metal) shows the big differences in how they are designed, how they work, and how they perform in the clinic.

| Feature | Flexible Horseshoe Dentures (Thermoplastic) | Conventional Rigid Partial Dentures (Acrylic/Cast Metal) |

| Major Connector | Flexible, palateless (upper) or lingual bar (lower). No rigid framework. | Rigid, usually cast metal (Co-Cr) or thick acrylic plate. |

| Support Mechanism | Mainly supported by the gums because there are no hard rests. | Mainly supported by teeth (cast metal) or a mix of teeth/gums (acrylic) using rests. |

| Stress Distribution | Spreads forces more evenly over the gums, but puts more stress on the gums. Less stress on supporting teeth. (FEA: Alqutaibi et al., 2022) | Moves forces to supporting teeth through rests, reducing stress on the gums. |

| Retention | Flexible clasps fitting into grooves (up to 0.5mm+). Looks good but may lose grip over time. | Rigid metal clasps (circumferential, I-bar) that can be adjusted for a precise grip. Looks less good. |

| Aesthetics | Excellent. See-through, gum-colored base and clasps. Almost invisible. | Looks less good, especially with visible metal clasps. |

| Comfort | Usually more comfortable at first because it’s flexible and less bulky. | Can be less comfortable at first, might cause sore spots, more bulky. |

| Repairability | Difficult/Limited. Doesn’t bond well to regular materials. Often needs to be remade. | Easier. Can be relined, rebased, or repaired with acrylic or welding (metal). |

| Adjustability | Hard to adjust in the office. Needs special tools. | Easier to adjust in the office (grinding acrylic, adjusting clasps). |

| Long-Term Stability | Lower. Tends to move and lose its fit due to material bending over time. | Higher. More stable because of the rigid frame and tooth support. |

| Longevity/Survival | Lower (Avg 3.5-5 yrs, 5-yr survival 60-75%). Higher chance of breaking. | Higher (Avg 5-10+ yrs, 5-yr survival 80-90%). Lower chance of breaking (metal). |

| Impact on Gums | Could lead to faster bone loss because of more pressure on the gums (FEA prediction). | Lower risk of bone loss because of tooth support. |

| Impact on Abutments | Lower stress on supporting teeth. | Higher stress on supporting teeth (especially with poor design/rests). |

| Cost (Initial) | Usually cheaper than cast metal, more expensive than simple acrylic. | More expensive than flexible/acrylic (cast metal), cheaper than flexible (simple acrylic). |

| Cost (Long-Term) | Could be higher because they need to be replaced more often. | Could be lower because they last longer and can be repaired. (Economic modeling, 2023-2024) |

| Indications | Looks, metal allergy, undercuts, temporary use, gaps between teeth. | Many missing teeth, need for strong support/stability, long gaps, complex cases. |

| Patient Satisfaction | High initial comfort/looks, lower long-term happiness (grip/stability). | Lower initial comfort/looks, higher long-term happiness with how they work. |

The choice between flexible and rigid partial dentures is a trade-off between looks/initial comfort and long-term stability/durability. Rigid cast metal RPDs are still the gold standard for complex cases that need the most support and longevity. Flexible dentures are a great alternative for specific patient needs, especially when looks and comfort are the top priorities and the chewing demands are not as high. Hybrid designs that mix parts of both are starting to appear to close this gap.

Our Simple Process for a Perfect Fit

We make it easy to order our custom flexible dentures.

- Send Us Your Case: You can send digital files from your scanner or a physical mold.

- Design and Production: Our lab uses your information to create amazing flexible horseshoe dentures.

- Fast Delivery: We work quickly to get the final product back to your office.

Let’s now turn our attention to the benefits of our ultra thin horseshoe dentures. These dentures are a key part of our advanced flexible denture technology. They offer superior comfort.

Partner with a Leader in Dental Manufacturing

Ready to offer your patients the best flexible horseshoe dentures and ultra thin horseshoe dentures available?

Contact us today to send your first case or to ask for a full product catalog