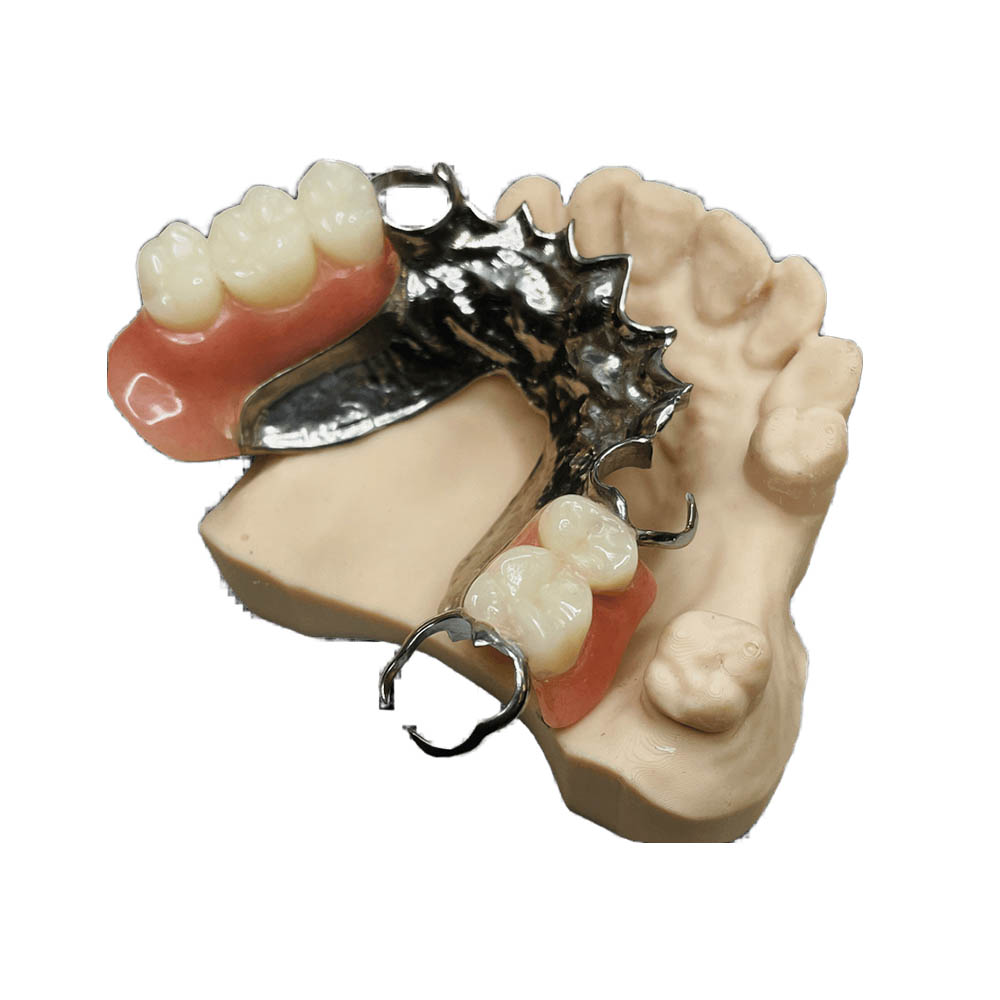

Metal Denture

As Istar Dental Lab, a top supplier of modern dental replacements, we are dedicated to providing the best quality and new ideas to our worldwide group of dentists, dental clinics, hospitals, and labs we work with. Our goal is to give our partners the detailed information they need to make smart choices, making sure patients get the best results and your practice runs smoothly.

High-Quality Metal Dentures for Your Practice

Why Our Metal Frame Denture is the Best Option

Choosing the right partner for your metal frame denture needs is very important. Our products offer clear benefits that you and your patients will appreciate. Here is a look at what makes our metal casting denture stand out. The careful design of our metal denture plate ensures great results.

Feature | Clinical Benefit for You and Your Patient |

Strength and durability of metal dentures | Fewer repairs and remakes. Patients get a long-lasting solution they can trust. |

Thin and lightweight design | Better patient comfort and willingness to wear them. The design is less bulky than other options. |

Hygienic properties of metal base | The polished metal surface is easy to clean. This helps maintain good long-term oral hygiene with dentures. |

Minimal tissue coverage | The design helps patients keep their sense of taste and touch. It also lowers the risk of Stomatitis. |

Thermal conductivity benefits | Patients can enjoy the natural hot and cold feelings of food and drinks. |

Support for remaining teeth | The design spreads chewing force well. This helps protect the health of the Abutment Tooth and Periodontal Ligament. |

The Best Materials and Design

Choosing the right metal mix for making dentures is very important, as it directly affects how well the denture works, how safe it is for the body, and how long it lasts. At Istar Dental Lab, we use a variety of top-quality metal mixes, each chosen for its special benefits.

Cobalt-Chromium (Co-Cr) Alloys Co-Cr alloys are a reliable standard for dental work, known for their excellent strength. They are very strong (tensile strength: 500–900 MPa), durable (yield strength: 450–800 MPa), and hard (Vickers hardness: 250–400 HV). Co-Cr alloys cost less than gold and are now often made using 3D printing methods. They are a top choice for RPDs because they are stiff and don’t wear down easily.

Titanium and Titanium Alloys Titanium and its alloys are famous for being very safe for the body. Titanium forms a stable TiO₂ protective layer, giving it great protection against rust, even in the tough conditions of the mouth. They are seen as the best choice for body safety, with very few allergic reactions reported. Titanium is hard to cast because it reacts at high temperatures, so it is often made using CAD/CAM or 3D printing. Titanium is a favorite for implants and abutments because it bonds well with bone (osseointegration) and is very light.

Gold Alloys Gold alloys are usually safe for the body, though some alloys with palladium have been linked to rare allergic reactions. They are easy to work with during casting and can be easily joined by soldering or welding. While they are softer, they last a long time in a patient’s mouth because they are flexible and don’t get harder with use. Gold alloys are the most expensive, with prices that change with world markets. They are still the best material for full-cast crowns and inlays/onlays when accuracy and long-term stability are most important.

Every metal casting denture is planned using a Dental surveyor, and using it is key to success. We design for every situation, from a Kennedy Class I, II, III, IV design to more difficult cases. The design of our metal denture plate considers all important points.

An Easy Process for Every Case

We make working with us simple and straightforward. Our process ensures a perfect fit and a happy patient. Making metal dentures should be a smooth process.

Step 1: Impressions and Planning: You start with good Impression techniques for partial dentures. This gives us a great model of the patient’s Edentulous Ridge and Alveolar Bone. We think about all the Biomechanical considerations in RPDs.

Step 2: Design: Our team designs the Cast metal framework design on the model, marking Guiding planes on abutment teeth and planning for Tissue stops on framework.

Step 3 & 4: Making, Finishing & Accuracy How metal dentures are made has changed a lot, moving from hands-on work that took a lot of time to very accurate computer-based methods. At Istar Dental Lab, we use a mix of both old and new methods to ensure top quality and fit.

Conventional Casting In the past, the lost-wax casting technique has been the main method for making metal dentures. This means creating a wax model of the framework, covering it in a special material, melting the wax out, and then pouring melted metal into the mold. While this is a proven method, it depends a lot on the technician’s skill and can sometimes have small errors due to shrinking, tiny holes, and rough surfaces, often needing a lot of finishing work.

CAD/CAM Milling The arrival of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) completely changed how dental replacements are made. Digital design allows for very accurate, custom frameworks based on mouth scans or regular impressions. CAD/CAM milling is a process where a solid metal block is carved down into the final framework shape. This method is more accurate and reliable than old casting methods, which means fewer mistakes and less wasted material.

Additive Manufacturing (3D Printing) – Selective Laser Melting (SLM) Selective Laser Melting (SLM) is a new and advanced 3D printing method that has changed how metal dentures are made. With SLM, a powerful laser melts metal powder layer by layer, building the framework directly from a computer design. This process offers amazing benefits:

- Excellent Fit and Accuracy: SLM frameworks always have a very tight and accurate fit at the edges, much better than frameworks made with old casting methods. This accuracy is because of the layer-by-layer computer control, which reduces shrinking and human error.

- Fewer Holes and a More Even Mix: SLM frameworks have fewer and smaller holes that are spread out evenly, which leads to better strength and a lower risk of breaking. The fast-cooling process also means a cleaner and more consistent metal mix.

- Create Complex Shapes with More Freedom: SLM lets us make very complex shapes that are custom-fit for each patient, including detailed patterns and thin connectors that are not possible or take too much work with old casting methods. This design freedom lets us create better frameworks that improve patient comfort and use.

- Faster Production: SLM greatly cuts down on the total time to make a framework compared to casting, making the process faster and easier for dental labs. This is especially helpful for labs that handle a lot of cases.

- Less Material Waste: SLM uses materials very wisely, with over 95% of the powder being recycled and very little waste. This makes it a more eco-friendly way to manufacture.

- Better Strength: SLM frameworks often have better strength and last longer without breaking compared to cast frameworks, because of their improved internal structure and fewer tiny holes.

Step 5: Try-In: We send the metal framework denture for a Framework try-in appointment at your clinic. This lets you check the fit before we add the teeth.

A Full Range of Solutions for Every Clinical Case

We offer a wide variety of metal dentures to meet every patient’s needs. Here is a look at what we offer and how they compare.

Denture Type | Best For | Comparison to Alternatives |

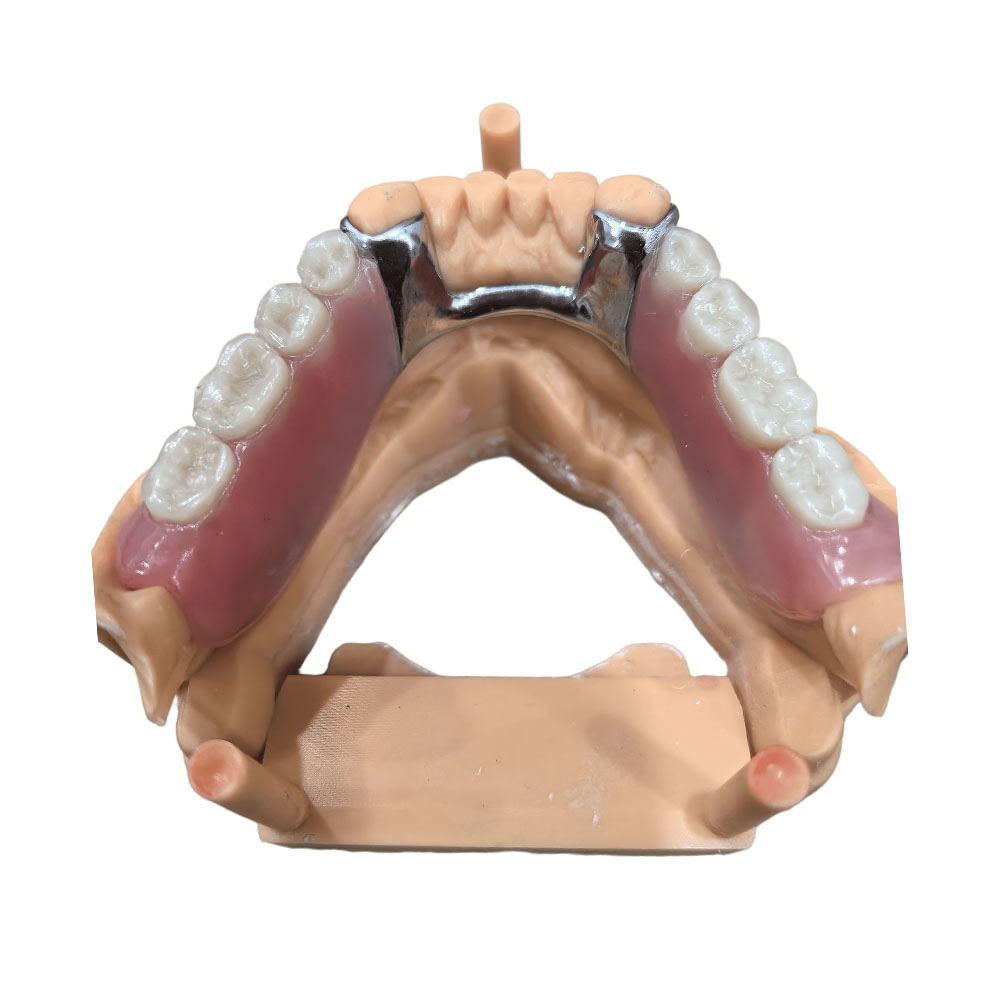

Metal upper partial denture | Patients needing a strong but thin palate design. | Metal vs. flexible partial dentures: Metal is stronger and more stable. |

Metal lower partial denture | Patients needing a stable fit that does not press on the gums or Gingiva. | Acrylic dentures vs. metal framework: The metal frame is less bulky and more hygienic. |

Unilateral metal partial | Replacing teeth on just one side of the mouth. | Valplast vs. chrome cobalt: Chrome offers better support for remaining teeth. |

Swing-lock partial denture | Cases needing extra retention for a very secure fit. | Fixed bridge as an alternative: A metal partial is removable and often less invasive. |

Overdenture | Patients with a few remaining teeth or implants. We can build a Metal framework for overdenture. | Metal partials vs. dental implants: A lower average cost of a metal partial can be a key factor for patients. |

Precision attachments for RPDs | Patients who want a beautiful smile with no visible metal clasps. | This option improves the look of metal clasps. |

We also offer a Light alloy denture, a Metal reinforced acrylic denture, and Telescopic dentures. Our team can also help with a Rotational path partial denture or Hybrid prosthesis options. We are experts in both Tooth-supported vs. tissue-supported partials.

Helping Patients and Providing Long-Term Care

We help you manage patient expectations and common issues. A good metal casting denture solves many problems before they start.

Patient Adjustment: We know there is an adjustment period. We give tips on Adjusting to a new metal denture, Eating and chewing with partials, and managing Speech with a palatal strap.

Common Problems: We can help with solutions for a Loose fitting partial denture and Sore spots from metal framework. We also give advice on rare issues like Metal denture allergy symptoms, a Metallic taste from new dentures, or Galvanic currents in the mouth.

Maintenance and Repairs: Our lab is ready for Relining a metal partial denture or Rebasing a cobalt chrome denture. We can also handle Repairing a broken metal denture, including Broken clasp repair options. We give clear instructions on How to clean a chrome denture.

Patient Conditions: We understand how conditions like Xerostomia (Dry Mouth), Malocclusion, or Alveolar Ridge Resorption can affect a case. We design the metal denture plate to work well with these conditions.

Work with Us for the Best in Dental Care

At Istar Dental Lab, we are focused on using these new technologies and materials to provide our partners with the highest quality metal dentures. We believe that by combining our knowledge with these new ideas, we can continue to offer solutions that not only fix chewing problems but also greatly improve the quality of life for patients everywhere. We invite our partners to work with us to explore these new methods, ensuring that together, we remain as leaders in making excellent dental products.

Common Questions About Metal Dentures

A: With good care, cast partial dentures can last 7-10 years or more.

A: Yes! Our precise fits mean less rubbing and sore spots.

A: Yes, most metal partial dentures can be fixed if damaged.

A: Standard cases take 5-7 working days. Rush service is available.

A: Yes, all metal dentures from ASD Dental Lab have a full 1-year warranty.