Partial Dentures For Front/Back Teeth

Your Trusted Partner for Custom Partial Dentures For Front/Back Teeth

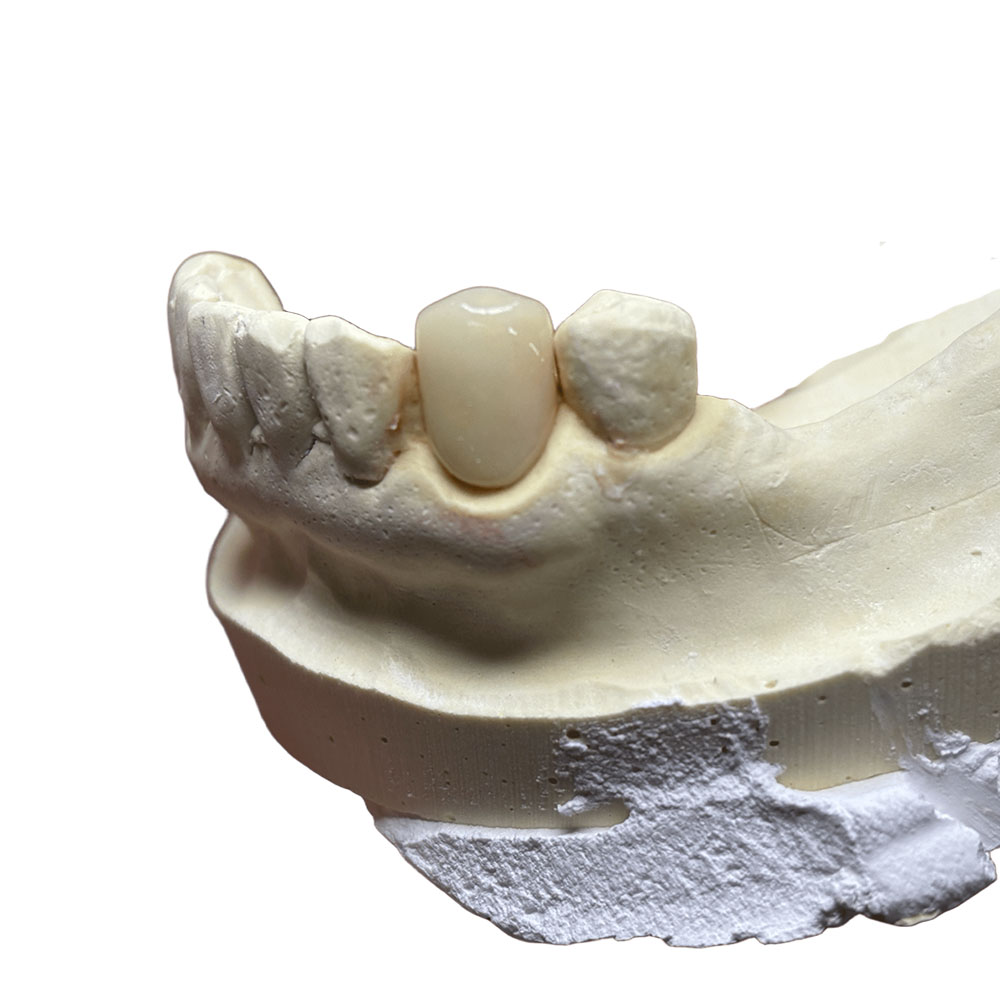

Partial dentures are removable devices made to replace one or more missing teeth while saving the remaining natural teeth. Their main purpose is to help with chewing, improve looks, and make the patient’s life better overall. While the main goal is the same, the special job and things to think about for partial dentures are very different when dealing with missing teeth in the front versus the back of the mouth.

In the front of the mouth (incisors and canines), the main focus of partial denture design is on looks and speech. Missing front teeth can greatly affect a patient’s smile, self-confidence, and ability to say certain sounds. Because of this, front partial dentures must blend in perfectly with the natural teeth, making the false parts less visible and making sure speech sounds normal.

On the other hand, in the back of the mouth (premolars and molars), the focus is mainly on chewing power and how chewing force is spread out. These teeth take most of the chewing pressure, and them being gone can weaken a patient’s ability to chew food well, which can cause stomach problems and pain. Back partial dentures are made to be very strong and stable to handle strong biting forces and stop other teeth from moving or bone from shrinking.

Understanding these different needs is very important for good treatment planning and getting good results with the dentures. Istar Dental Lab uses this basic knowledge to custom-make every partial denture, making sure it meets the special needs for both use and looks for the part of the mouth it’s made for.

A Full Range of Denture Solutions

Every patient is different. We offer a wide range of tooth replacement options to meet every need. Our work helps you with fully restoring smiles for your patients. We make it easy for you to offer the best solutions.

- Cast Metal Partial Dentures: These are a very strong choice. They have a thin, light metal framework. This is often made from a cobalt-chromium alloy or Titanium. The false teeth are attached to a gum-colored acrylic base. Metal clasps hold the denture securely. These are great for long-term use and for replacing many teeth. They are especially good as dentures for back teeth where chewing strength is needed.

- Flexible Partial Dentures: These are a modern, comfortable option. Made from materials like Valplast, they are metal-free partial dentures. The clasps are made of a flexible, gum-colored thermoplastic resin. This makes them nearly invisible. Many dentists choose flexible partial dentures for front teeth because they look so natural.

- Acrylic Partial Dentures: These are often called a flipper tooth or a removable bridge. They are made from a simple acrylic resin. They are a great, low-cost choice. An acrylic partial plate is often used as a temporary partial denture after a tooth extraction. It is also a good transitional partial denture while a patient waits for a more permanent solution. They are useful as simple front teeth dentures.

- Fixed Partial Denture (Dental Bridge): We also support cases that need a Fixed Partial Denture (FPD). This includes a resin-bonded bridge. It is a non-removable option. It is anchored to the abutment teeth (the supporting teeth) next to the gap. Often, a dental crown is needed on these teeth. This is a great alternative to a Removable Partial Denture (RPD).

Advanced Technology and Body-Friendly Materials

The way partial dentures have changed is closely tied to improvements in materials and how they are made. Istar Dental Lab is proud to use many different modern materials and both traditional and new digital methods to make sure they have the best strength, looks, and function for every patient.

Diverse Range of Materials

Choosing materials for making a partial denture is a very important choice, balancing strength, looks, how well they work, and cost.

Metal Alloys (e.g., Cobalt-Chromium, Titanium)

- Properties: Cobalt-chromium (CoCr) alloys have long been the top choice for back partial dentures because of their great strength, stiffness, and being hard to break under chewing forces. They bend without breaking and last a long time. Titanium, while it costs more, is very safe for the body and is lighter.

- Functional Performance: Perfect for back areas that take a lot of pressure, giving strong support and steadiness.

- Aesthetics: Limited. Metal clasps can be seen, especially in the front, which is a big problem for how it looks for many patients.

- Fabrication: Traditionally made by casting, but more and more they can be made with digital milling or 3D printing.

Acrylics (Polymethyl Methacrylate – PMMA)

- Properties: Can be used in many ways, doesn’t cost a lot, and is easy to fix. Stronger acrylics last longer.

- Aesthetics: Good for denture bases and false teeth, with many shades to choose from. However, acrylic clasps can be big and can break easily.

- Functional Performance: Good for denture bases and some partials supported by teeth, but not as strong for high-stress areas or for staying in place for a long time compared to metal or other advanced materials.

- Fabrication: Made with traditional heat-curing or cold-curing, and now more often with 3D printing.

Flexible Resins (e.g., Polyamides, Nylon-based materials)

- Properties: Very flexible, strong against impact, and see-through.

- Aesthetics: Blends in very well with the gums and can be used to make “invisible clasps” that match the gums, making them a great choice for front partial dentures where looks are most important.

- Functional Performance: While they are comfortable and look good, they can lose their shape over time and are not as good for back areas that take a lot of pressure. Studies have shown they don’t stay in place well over time and the clasps can get weak or break when used in the back.

- Fabrication: Made by injection molding or direct 3D printing.

Polyetheretherketone (PEEK)

- Properties: A strong thermoplastic polymer with great strength that lasts a very long time without getting weak. Its low weight makes the denture lighter, which is more comfortable for the patient.

- Aesthetics: It is naturally a beige color, but it can be covered with composite to better match tooth color, offering a choice without metal. It’s not as see-through as acrylics or flexible resins.

- Functional Performance: It’s great for chewing and doesn’t wear down the other teeth. Clinical studies show it breaks very rarely in back partial dentures, making it a great choice for these areas that take a lot of pressure.

- Biocompatibility: It’s gentle on the gums, plaque doesn’t build up easily, and it’s unlikely to cause allergies. Studies show the edges continue to fit well after 5 years.

- Cost-Effectiveness: The material costs more at first, but you save money over time with fewer adjustments and repairs.

- Fabrication: Mostly made with CAD/CAM milling, but new ways to 3D print PEEK are being developed. Special treatments help the covering material stick better.

Zirconia

- Properties: A ceramic material that is very resistant to cracking and has very high strength. It is very hard and doesn’t wear down easily, but it can snap and isn’t as flexible as PEEK.

- Aesthetics: Very see-through and the color doesn’t change, making it perfect for strong frames and clasps where looks are very important, especially with digital color-matching systems.

- Functional Performance: Great for strong frames but can break completely if too much pressure is applied. Not a good choice for flexible clasps in high-stress areas because it is so stiff.

- Biocompatibility: It’s gentle on the gums, but the connecting parts might chip. We are still learning about how it performs over many years in partial denture frames.

- Cost-Effectiveness: Costs the most to start, which makes sense mostly for cases where looks are the top priority.

- Fabrication: Can only be made with CAD/CAM milling because it needs to be heated. Special treatments help resin stick to it.

Fabrication Techniques: Old vs. New Methods

Istar Dental Lab uses both older, proven methods and new digital methods to make sure the work is accurate and fast.

Conventional Fabrication

- This involves taking traditional impressions, pouring a stone model, making a wax model, casting (for metal frames), and finishing by hand.

- It requires a lot of hands-on skill and many lab steps.

- While it can make high-quality dentures, it can take a long time and mistakes can happen.

Digital Fabrication Workflows

The use of digital tools has completely changed how partial dentures are made, offering better accuracy, speed, and the ability to make the same thing again.

- Intraoral Scanning: This takes the place of traditional impressions, giving very exact 3D digital pictures of the patient’s mouth. This is more comfortable for the patient and wastes less material.

- CAD (Computer-Aided Design): Denture frames are designed on a computer with special software. This allows for an exact fit on the supporting teeth and gums, making the fit and pressure points better. AI programs for design are being used more and more to make this process automatic and better, using a lot of information to create custom frames in minutes.

- CAM (Computer-Aided Manufacturing): The digital design is then sent to be made.

- Milling: For hard materials like PEEK, zirconia, and some metal alloys, frames are carefully carved out of special blocks.

- 3D Printing: For resins (both flexible and hard) and some metal alloys, frames are printed layer by layer. New 3D printers that can use different materials at once are becoming available, printing hard and soft materials at the same time. This allows for making partial denture frames with built-in soft parts for the gums and flexible clasps.

- Workflow Efficiency: Digital methods make the whole process much faster (by 30–50%) and make the fit more exact. This means fewer adjustments are needed at the dentist’s office and patients are happier.

Our Simple, Teamwork-Based Process

We want to make working with us easy and smooth. We have a clear process from start to finish. We try to make our steps feel natural and make sense.

- Consultation and Submission: You start with a dental consultation with your patient. You can send us a digital scan or traditional dental impressions using an impression tray. Include any notes about the patient’s needs.

- Design and Review: Our technicians use your information to design the denture. We pay close attention to the path of insertion and the Kennedy classification. We design the major connector, minor connector, and occlusal rests so the denture is steady and stays in place. We use guide planes for a smooth fit.

- Fabrication: We create the denture using the chosen materials. An articulator helps us get the bite just right. We create the denture base and set the teeth.

- Try-In and Final Fitting: We send you a wax try-in model if needed. This lets you check the fit and look. After your approval, we finish the final partial plate. You then have the final fitting with your patient. We are always here to support you with any needed adjustments.

Helping You Manage Patient Expectations

We understand that you are not just treating teeth; you are treating people. A big part of success is helping patients get used to their new false teeth. Our well-made dentures help make this process easier. We are careful with our words to be both clear and professional.

- Comfort and Fit: A well-fitting denture reduces the chance of sore spots from dentures and gum irritation. This means fewer follow-up appointments for adjustments. Our goal is a comfortable fit from day one.

- The Adjustment Period: We know there is a denture adjustment period. Patients need time for getting used to dentures. This includes learning about speaking with dentures and eating with partial dentures. We suggest patients start with soft foods for denture wearers.

- Denture Care Instructions: A good fit makes care easier. We support you in teaching patients about denture care instructions. This includes how to use a denture brush and denture cleaner. Proper oral hygiene with dentures helps prevent plaque buildup and bad breath with dentures. Patients should learn about storing partial dentures in a soaking solution.

- Aesthetics: We know looks are important, especially for front partial dentures. We work hard to make restorations that blend in perfectly. This work is very important for good how the mouth works and a happy patient.

For patients looking at other choices besides partial dentures, such as a single tooth implant or an implant-supported bridge, our partials can be a great first step. Sometimes, a patient may need a bone grafting or sinus lift procedure first. An oral surgeon or prosthodontist can perform these. A dental hygienist can help with care.

Choose us as your partner. We provide the knowledge you need to deliver excellent dental solutions that look good. We help you keep the shape of the patient’s face. Let’s work together to create healthy, happy smiles with high-quality front teeth dentures and partial dentures for front teeth.