Partial Implant Dentures

Istar Dental Lab: Leading the Way in Making Partial Implant Dentures

As one of China’s top five dental labs, Istar Dental Lab is proud to serve dentists, clinics, hospitals, and other dental labs around the world. We are committed to providing the best quality, accuracy, and new ideas in dental restorations, especially for the challenging and fast-changing world of partial implant dentures.

The Benefits of Partial Implant Dentures

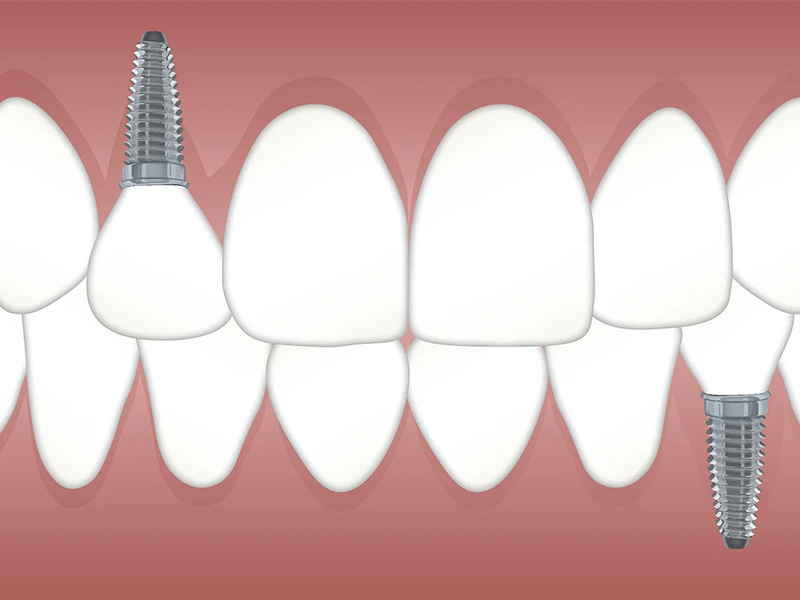

Partial implant dentures (PIDs) are an advanced type of dental restoration designed to replace several missing teeth. Unlike regular dentures, PIDs use the incredible stability and support from osseointegrated dental implants. This difference is very important because it changes how the denture works with the mouth, leading to better results for patients.

Why They Are Important and How They Work Better

PIDs are a great choice, especially when traditional options won’t work well. They are extremely useful in Kennedy Class I and II situations, where back teeth are missing on one or both sides and there is no natural tooth for support.

Studies consistently show the major benefits of PIDs. Patients can chew better, are more satisfied, and their dentures last much longer. From a functional standpoint, using implants greatly reduces how much the denture moves or rotates, puts less pressure on the gums, and most importantly, helps protect the remaining jawbone.

- Up to 50% less movement compared to regular partial dentures.

- A 30–40% increase in bite force compared to regular partial dentures.

- Long-term studies show that 92% to 98% of PIDs are still successful after many years.

- Patient feedback consistently rates PIDs higher for their excellent comfort, function, and appearance.

Our Essential Part in Your Work

At Istar Dental Lab, we are the key connection that carefully turns your detailed clinical plans into accurate, functional, and beautiful restorations. Our main services include:

- Processing Impressions: Whether you send us traditional molds or modern digital scans, our first step is to carefully process them to create highly accurate models.

- CAD/CAM Framework Design: Using the latest CAD/CAM software, we digitally create the detailed frameworks for PIDs, making sure they fit perfectly and are strong and stable.

- Choosing and Placing Attachments: We are experts at choosing and adding a wide variety of attachment systems, from flexible ones (like ball or magnetic attachments) to very precise ones (like bar-retained systems).

- Ensuring a Passive Fit: A key part of implant work is making sure all components fit without any stress. We use strict procedures to guarantee this “passive fit,” which is vital for preventing bone loss around the implant and ensuring long-term success.

By using digital scanning, virtual design, and modern manufacturing (like 3D printing and selective laser melting), we have greatly improved accuracy, cut down on production time, and can now offer more customization than ever before. This move to new technology has changed our role from just making devices to being a design partner you can consult with.

Types of Dentures and Our Design Approach

Our skill in making partial implant dentures comes from a deep knowledge of the different types of restorations and the specific design rules for each one.

Denture Types We Make:

- Fixed Partial Implant Dentures: These are like screw-in bridges. Our design goal is to create a perfect, stress-free fit and to spread chewing forces evenly across the implants.

- Removable Implant Dentures (Overdentures): These are made to be easy for patients to clean. Our design balances a secure hold with easy removal.

- Bar-Retained Prostheses: These use custom-made bars, usually from titanium or cobalt-chrome. The bar’s design is key to spreading forces evenly across all the implants.

- Hybrid Prostheses (Fixed-Removable): For these, we carefully manage bite forces and make sure the internal structure is strong enough to support the teeth, often using a design that stabilizes the entire arch.

Our Focus on Function and Structure:

- Passive Fit: Getting a stress-free fit is our top priority. We use digital checks, like photogrammetry and digital scans of the abutments, to confirm accuracy.

- Cantilever Length: We strictly control the length of any extensions, keeping them under 15 mm or 1.5 times the AP spread of the implants to reduce harmful leverage forces.

- Space Between Jaws: We follow clear rules for how much vertical space is needed, such as 12–15 mm for fixed hybrid dentures and 14–16 mm for bar-retained overdentures.

Advanced Materials and How We Make Dentures

We carefully choose our materials and use the latest manufacturing methods to ensure the best strength, safety, and appearance for every restoration.

Highlights of Our Materials:

- Zirconia: Offers very high strength (over 900 MPa), is very safe for the body, and looks great. It’s used for frameworks and full-contour dentures where appearance is key.

- Titanium: Our top choice for frameworks because it is safe, resists wear, and has a great balance of strength and low weight.

- PEEK (Polyetheretherketone): A modern polymer that has a flexibility very similar to natural bone. It’s light, absorbs shock well, and is perfect for patients with metal allergies.

- Cobalt-Chrome (Co-Cr): A dependable choice for frameworks when high strength and stiffness are most important.

Our Modern Manufacturing Methods:

- Milling (CAD/CAM): This is our main method for zirconia, PEEK, and PMMA. It provides amazing accuracy and consistency and works perfectly with our digital process.

- Additive Manufacturing (AM) / Selective Laser Melting (SLM): We use this to directly create frameworks from cobalt-chrome and titanium powder. This technology lets us make very complex shapes that would be impossible otherwise.

- 3D Printing (DLP/SLA): We use this to make temporary dentures, try-in models, and very accurate guides, which is a fast and affordable solution for these needs.

The Advantage of Digital Technology

At Istar Dental Lab, we use a complete digital process, with advanced CAD/CAM and 3D printing to set a new standard for accuracy, speed, and quality.

- Amazing Precision: Digital methods can create fits with errors of less than 50μm, a huge improvement over older methods. This accuracy is essential for a stress-free fit on implant parts.

- Faster Production: We have seen up to a 60% reduction in production time for partial implant dentures using our digital process. The average time to complete a case drops from 10–14 days to just 4–6 days.

- Better Customization: Smart AI tools in our CAD software can automatically suggest the best designs for bars, clasps, and even the bite based on each patient’s unique anatomy.

- The Power of AI/ML: We use Artificial Intelligence for automatic design help, bite-pattern optimization, and even to spot printing errors in real time. This reduces the need for manual checks and improves our success rate on the first try.

Our Promise of Quality and Excellence

Quality is the foundation of everything we do at Istar Dental Lab. We use a multi-step Quality Assurance (QA) system that is one of the strictest in the industry.

- Global Standards: We follow the highest quality rules, including ISO 13485 certification for making medical devices.

- Digital Tracking: We use modern Lab Information Management Systems (LIMS) to record every step of the production process, which helps us meet international standards.

- Proven Results: By using AI to help spot defects, we have greatly reduced our remake rate to less than 2%.

- Reliable Delivery: We closely monitor our performance, aiming for a delivery time of less than 7 days for partial implant dentures and an on-time delivery rate of over 98%.

By combining these modern technologies with strict quality standards, Istar Dental Lab is your best partner for dental restorations. We give you the power to provide reliable, beautiful, and long-lasting results for even your most difficult cases. Partner with us to raise the level of care at your practice and achieve complete patient satisfaction.