PFM Cantilever Bridge

A Guide to PFM Cantilever Bridges from Istar Dental Lab

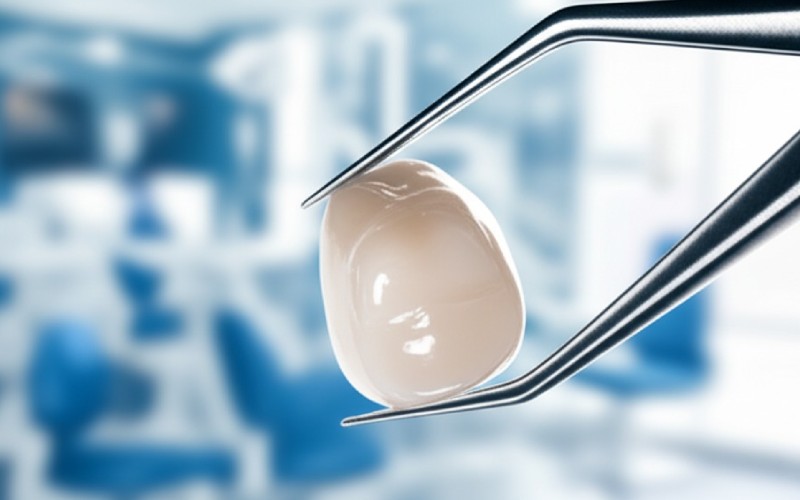

As a top global maker of modern dental products, Istar Dental Lab is focused on providing solutions that are incredibly accurate, long-lasting, and look great. Porcelain-Fused-to-Metal (PFM) cantilever bridges are a proven and very effective way to fix teeth, made to replace missing teeth when a supporting tooth isn’t available or usable on one side. This dental piece has a pontic (the fake tooth) that is held up on only one side by a cap, which is glued to a supporting abutment tooth.

They are mainly used to replace a single tooth, especially at the front or middle of the mouth. They are also used for back teeth in certain situations where getting a dental implant isn’t a good idea because of issues with the patient’s jaw structure (like not enough bone or being too close to important nerves) or other personal reasons (like health problems, cost, or what the patient prefers). Our goal at Istar Dental Lab is to perfect how we design and make these bridges, making sure they keep working well in modern dentistry.

When to Use a PFM Cantilever Bridge

Choosing the right patients and clearly understanding when to use—and when not to use—these bridges is extremely important for them to last a long time. While these bridges are a great solution, using them requires a careful look at each patient’s situation and oral health.

Good Times to Use It (Clinical Indications):

PFM cantilever bridges are mainly used for replacing a single tooth, especially in the front and middle areas of the mouth where looks are important and chewing forces are generally weaker. They are also a good option for back teeth when:

- A supporting tooth is missing on the far side, and a dental implant can’t be placed due to the jaw’s shape (like not enough bone, or being too close to the mandibular canal or maxillary sinus).

- Overall health problems prevent implant surgery.

- The patient’s preference or budget makes getting an implant not a practical option.

- The supporting abutment teeth are strong, healthy, and have good gum and bone support.

When Not to Use It (Contraindications):

Reasons to avoid this type of bridge must be checked carefully:

Definite Reasons to Avoid (Absolute Contraindications):

- Not Enough Support: If the abutment teeth have unhealthy gums, are very loose, or don’t have enough root to hold on, they can’t handle the extra pushing forces from a cantilever.

- Uncontrolled Grinding Habits: Severe bruxism (teeth grinding) or clenching greatly increases the risk of physical problems (like the porcelain or the connector breaking, or the support tooth being overloaded). This is a strong reason to avoid a cantilever unless the habit is carefully controlled with something like a night guard.

- Poor Oral Hygiene: Patients with a history of widespread cavities or who don’t clean their teeth well are at a high risk of getting new cavities around the supporting teeth.

- A Bad Bite: If the patient’s existing bite puts too much sideways or uneven pressure on the planned cantilever pontic, it’s not a good idea unless the bite can be permanently fixed.

- Long Bridge Span: Cantilevers that replace more than one tooth, especially in the back of the mouth, are generally not recommended because the pushing forces grow much, much bigger and lead to high failure rates.

Reasons to Be Cautious (Relative Contraindications):

- Low Bone Density: Weaker bone (D3/D4) where the abutment tooth is can focus stress in one spot and increase the risk of the tooth or bone breaking down.

- Single Support in High-Stress Areas: Using a single abutment tooth for a cantilever in an area with strong chewing forces (like back molars) is risky. It requires a very strong support tooth and very careful bite adjustments.

- Looks Might Be an Issue: In areas where appearance is very important, the metal base of a PFM bridge can sometimes create a gray line at the gums. This might be a reason to avoid it if all-ceramic options are possible.

At Istar Dental Lab, we work closely with dentists to look at these issues. We give expert advice on picking materials, changing designs, and lowering risks to make sure every patient gets the best and most reliable result.

The Istar Advantage: Top Quality Materials

At Istar Dental Lab, we are experts in making dental products. We use only the best materials for every PFM cantilever dental bridge.

| Material Type | Description |

| Metal Substructure | The strong core of the bridge is a metal alloy substructure. We use a metal coping that fits perfectly. We offer different Metal Alloys to meet your needs. This includes High noble alloys with Gold and Palladium, and strong Base metal alloys like Cobalt-chromium and Nickel-chromium. These metals offer great durability. |

| Porcelain Layer | We use a beautiful ceramic veneer made from Feldspathic porcelain. We start with an opaque porcelain layer to hide the metal. Then, we build up the tooth shape. The porcelain is heated in a special Porcelain Furnace in a process called sintering. This fuses it to the metal. The result is a tooth that looks real and has great aesthetics. |

The Istar Advantage: Our Making Process for PFM Cantilever Bridges

Making PFM cantilever bridges at Istar Dental Lab is a very careful process that mixes traditional skills with new technology. Our workflow is set up to ensure accuracy, strength, and great looks.

Impression Handling and Model Work

The process starts by cleaning and checking the impressions we receive. We then use them to pour very accurate stone models. These models are put together to copy the patient’s bite, which is a key step for making sure the final bridge is precise.

Cantilever Design

The design step is all about how forces work, carefully planning the abutment and pontic to reduce harmful pushing forces. Our technicians use both classic wax models and modern CAD software to perfect the design and make sure pressure is spread out evenly.

Wax-Up and Framework Making

A precise wax model of the framework is made, either by hand or with digital design and 3D printing. This model is then placed in a mold and heated to remove the wax, getting it ready for the metal to be cast.

Alloy Selection and Casting

We pick a suitable non-precious or precious alloy and use standard industry machines to cast it into the framework. After casting, the framework is cleaned, sandblasted, and carefully checked for a good fit and solid structure.

Framework Try-In and Adjustment

The metal framework is tested on the master model to check for a perfect, stress-free fit at the edges under a microscope. We make any needed changes before the framework is heated in a furnace to create a strong bond for the porcelain.

Porcelain Application and Firing

Our skilled artists apply porcelain in layers, starting with a non-see-through layer to hide the metal, then adding dentin and enamel layers to build a natural-looking tooth. Each layer is fired at a specific temperature in a Porcelain Furnace to make sure it’s strong and the right size.

Shaping, Glazing, and Staining

The bridge is expertly shaped to its final form and then polished. One last firing adds a glaze and custom colors to give it a natural shine and perfectly match the patient’s other teeth.

Final Finishing and Quality Control

The finished bridge goes through one last quality check, where we double-check the edges and bite contacts. It is then cleaned with an ultrasonic machine and given a final polish, with records kept for every step.

Fixing Common Technical Problems

We find and fix common technical problems like tiny holes in the casting or porcelain chipping. Our solutions depend on following strict work rules, checking our equipment regularly, and keeping our technicians trained.

Using Digital Workflows

Istar Dental Lab uses digital methods a lot. We use digital impressions and CAD/CAM to make highly accurate frameworks. This modern way of working cuts down on human error and improves consistency for a better final fit.

Technician Skill and Work Rules

The skill of our experienced technicians is the main reason we get such a great fit and appearance. We make sure the quality is always high by following and tracking strict Standard Operating Procedures (SOPs) for every step of the process.

The Full Process with Istar Dental Lab

When you work with a Dentist or Prosthodontist, here is the process for a full crown and bridge:

- Consultation: You have a dental consultation with your patient and get their full permission. Maybe they get a second opinion.

- Preparation: The abutment tooth is prepared using a Dental Handpiece and Dental Burs. This involves carefully shaping the tooth.

- Impression: You use gingival retraction and take dental impressions. You can send us a physical model or a digital scan.

- Fabrication: Our dental lab gets to work. We use an articulator to copy the patient’s bite on their Mandible and Maxilla. Then we make the bridge.

- Cementation: You receive the final PFM Cantilever Bridge. You try it in and then use Dental Cement or Composite Resin to place it for good.

How We Operate: Pricing, Turnaround Times, and Service

Istar Dental Lab’s efficiency is a key part of the value we offer. We know that clear pricing, reliable timing, and great service are essential for our partners.

Pricing Models

At Istar Dental Lab, our main goal with pricing is to give you great value by offering high-quality work at very competitive prices. We do this with a smart plan that uses our large size, efficient technology, and global position. By buying the best materials in large amounts and using modern digital workflows, we cut down on waste and labor costs, passing those savings on to you.

Average Turnaround Times

We are proud of our fast work, which we do without sacrificing quality. Our standard time for making PFM cantilever bridges is usually 7–10 business days after we get the impressions. For urgent jobs, we offer a rush service (3–5 days) for an extra fee. Our major investment in digital tools, including CAD/CAM systems, lets us sometimes finish jobs in as little as 5–7 days.

Key Service Information

Great service is a core part of our partnerships:

- Strong Communication: We give you a dedicated person to manage your cases, online portals to track them, and live chat or phone support. Our digital order forms make the process smooth.

- Warranty Policies: We stand behind our work. Our PFM cantilever bridges usually come with a 3 to 5-year warranty on the framework. Our tough quality control leads to very low remake rates (under 2%), which shows how serious we are about quality.

- Technical Support and Education: We offer tech support when you need it and can even help during patient appointments for difficult cases. We also provide webinars and other learning resources to help us all grow together.

Our Promise to You

At Istar Dental Lab, we are your partners. We help you with fixing your patients’ smiles. We follow all American Dental Association (ADA) standards. We know that good dental work leads to happy patients.

We offer support for all your needs. Contact us today to learn more about our PFM cantilever dental bridge and other services. Let’s work together to create healthy, beautiful smiles