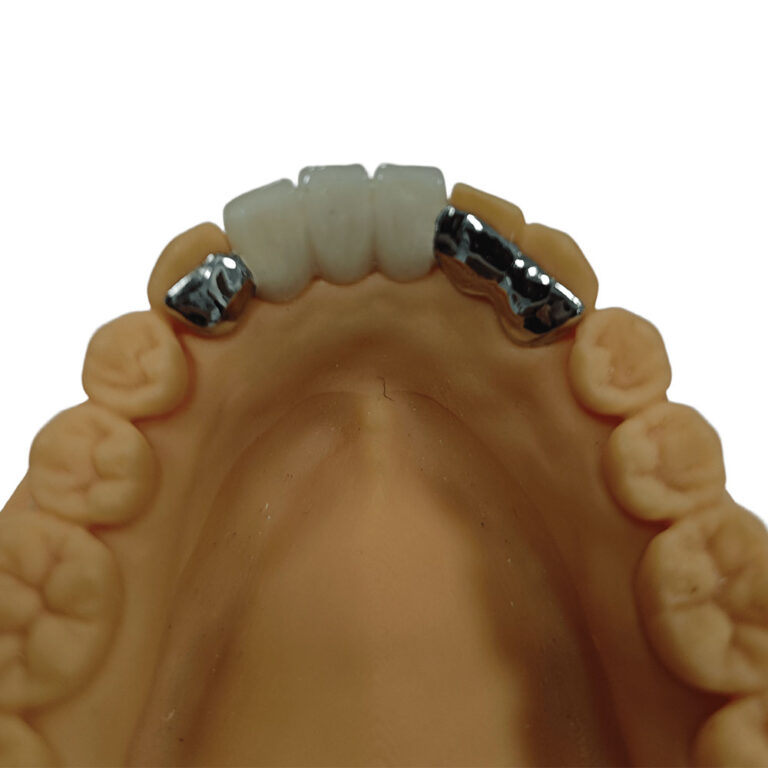

PFM Maryland Bridge

PFM Maryland Bridges: A Simple Guide from Istar Dental Lab

At Istar Dental Lab, one of China’s top dental labs, we are dedicated to giving our clients around the world—including dentists, dental clinics, hospitals, and other labs—the best quality dental restorations. We are skilled in many types of dental work, and among them, the Porcelain-Fused-to-Metal (PFM) Maryland bridge is a great example of a gentle but strong way to replace teeth.

The PFM Maryland Bridge: A Gentle and Good-Looking Solution

The PFM Maryland bridge, a type of resin-bonded fixed partial denture (RBFPD), is a big step forward in gentle dental care. This new method saves as much of the natural tooth as possible on the neighboring teeth, unlike older methods that use full crowns.

Its main goal is to replace missing teeth so they look good and work well, especially when it’s very important to prepare the neighboring teeth as little as possible. It is a great option for replacing a single front tooth, holding space for young patients, or as an alternative when more involved treatments are not recommended. At Istar Dental Lab, we use our long experience to make restorations that meet today’s needs for looks, strength, and comfort.

Materials and Smart Design

The success and long life of PFM Maryland bridges are closely connected to the way their materials work together and the forces they handle in the mouth. Our lab carefully chooses and prepares materials to make sure they work perfectly.

Metal Alloys and Porcelain Systems

The metal frame is made from either noble or base metal alloys, chosen for the best strength and for being safe for the body.

- Noble Alloys: These include high-gold, palladium-silver, and palladium-based alloys. They are liked because they resist wear and rust very well and are safe for patients. Their flexural strength is usually between 400–600 MPa.

- Base Metal Alloys: Nickel-chromium and cobalt-chromium alloys are often used because they are very strong (flexural strengths of 800–1200 MPa) and offer good value. Our process makes sure all alloys meet strict safety standards.

The types of porcelain are chosen for their appearance and how well they work with the metal. This includes feldspathic and leucite-reinforced porcelains, which are stronger and less likely to chip. A very important part is carefully matching the Coefficient of Thermal Expansion (CTE) of the metal and the porcelain to ensure a strong bond and prevent chipping or separating.

Designed for Strength

Knowing how chewing forces spread out is key to designing strong restorations. Our designs are specially made to handle chewing forces and provide long-term stability.

- Connector Design: We shape the connectors in the best way to direct forces properly and reduce stress on the supporting teeth. We aim for a connector height of at least 4 mm for the best strength.

- Retainer Design: We design the wings to spread out forces evenly while keeping the bridge small, balancing strength with saving the natural tooth.

- A Strong Bond: A strong bond for our restorations is very important. We use special surface treatments like sandblasting with 50 μm aluminum oxide particles and, for some alloys, tin-plating or silica coating. These steps create a better surface for bonding and can increase bond strength by 10–30%.

Clinical Uses and Choosing Cases

Carefully choosing the right cases is very important for reliable success. We make our PFM Maryland bridges to fit a number of clinical needs.

Good Uses for This Bridge

- Single Front Tooth Replacement: Especially when the teeth next to the gap have few or no fillings.

- Holding Space: For young patients who are waiting for dental implants after they have finished growing.

- A Gentle Approach: When saving the natural tooth is the top priority, or when more involved treatments are not recommended.

- Specific Situations: For patients born without lateral incisors or for teens who have lost a tooth due to an accident.

When Not to Use This Bridge

To get the best results, it’s important to know when not to use this bridge.

- Absolute Reasons Not To: Severe grinding or clenching habits (bruxism), not enough enamel on the supporting teeth, active gum disease, or long-span missing tooth gaps.

- Relative Reasons Not To: A deep bite, loose supporting teeth, poor oral hygiene, or supporting teeth with large fillings.

Our Lab Process and Quality

At Istar Dental Lab, making PFM Maryland bridges is a very precise process, combining skilled handiwork with the latest digital tools to ensure a great fit, strength, and appearance.

CAD/CAM Milling of Metal Frames

Our modern digital process is a big improvement in accuracy and consistency.

- Getting Digital Data: We use very accurate 3D models from digital scanners in the dental office or our lab.

- CAD Design: The frame is carefully designed using advanced CAD software. This gives us precise control over the thickness, shape, and size of all parts.

- CAM Manufacturing: The frame is then milled from a solid block of high-quality metal (like cobalt-chromium) using advanced 5-axis milling machines.

Milled frames always show a better fit at the edges compared to older casting methods. They are also more uniform and solid, which greatly lowers the risk of weak spots or defects.

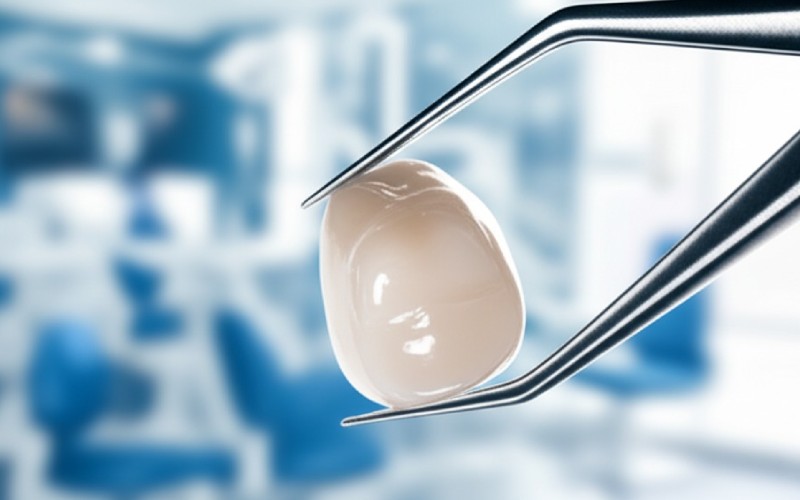

Layering Porcelain for a Natural Look

- Preparing the Surface: The frame is heated to create a special oxide layer, which is needed for the porcelain to bond chemically to the metal.

- Applying Opaque Porcelain: We apply two thin layers of opaque porcelain to completely hide the metal underneath and create the base color.

- Building the Tooth Shape: Our skilled technicians then carefully apply thin layers of dentin and enamel porcelains to build the tooth’s natural shape and create a lifelike look.

Quality Control and Standards

We are totally committed to quality. We use strict quality checks during every step:

- Checking for Precision: We use digital microscopes and 3D scanners to check the fit at the edges, the internal fit, and the strength of the connectors.

- Material Standards: All our materials and methods follow international rules, including ISO 9693, which sets requirements for bond strength and safety.

How It Compares to Other Options

Choosing the best option means comparing the different choices. The PFM Maryland bridge offers a unique mix of benefits.

| Feature | PFM Maryland Bridge | Conventional FPD | Dental Implant |

| Tooth Preparation | Very little drilling; saves the natural tooth. | The most drilling; requires removing a lot of the supporting teeth. | Needs surgery; may require bone grafts. |

| Strength | High flexural strength with a strong metal frame. | Very high strength because it covers the whole tooth. | Very strong and durable. |

| Appearance | Good appearance with modern porcelain layering. | Good to excellent, depending on the material. | Can look excellent with ideal gum tissue. |

| Cost | Very good value; lower initial cost and less chair time. | More expensive because of more drilling and materials. | Highest initial cost. |

| Best For | A gentle, reliable, and affordable option to replace a single tooth, especially for younger patients or when saving the tooth is key. | Used when supporting teeth already have fillings or need crowns. | The “gold standard” for long life and saving bone, but it costs more and requires surgery. |

Why Choose Istar Dental Lab?

Fast and Efficient Service

By using a complete digital process from start to finish, we work more efficiently and reduce production times. This precise process means you get your PFM Maryland bridge cases faster, allowing for easier patient scheduling.

Great Value Solutions

Our PFM Maryland bridges are a great value, offering a good price for the long-lasting quality your practice needs. We provide this affordable option without cutting corners on the high-quality materials and work your patients deserve.

Full Clinical Support

We work with you from start to finish, offering expert advice on choosing cases and designing them to get reliable, successful results. Our team is here to give you the support you need to confidently give your patients back their smiles.