Removable

As Istar Dental Lab, one of the top five dental labs in China, we are dedicated to improving the field of dental prosthetics. We are your trusted partner. We provide high-quality removable dentures for dentists and their teams. This includes dentists, dental hospitals, and dental clinics of any size. We are a skilled removable dental lab that understands what you need. Our goal is to help you give your patients the best choices for replacing teeth.

Istar: Your Go-To Partner for Removable Dental Prosthetics

We know you need a lab that is on time, every time. You need products that make patients very happy. Our skilled team of Dental Technicians uses modern tools and methods. This helps us make prosthetics that look great and work well. Let us help you improve your patients’ quality of life and self-confidence.

Our Full Line of Removable Prosthetics

Removable dental prosthetics are very important options for patients who are missing some or all of their teeth. They are made to bring back normal mouth function, a good appearance, and a better quality of life. These devices can be taken out by the patient for cleaning. The way they are designed is based on giving support, hold, and steadiness while being safe for the tissues in the mouth.

Here is a look at what our removable dental lab can do for you and your patients:

Prosthetic Type & Key Features | Description & Materials | Common Clinical Uses |

Complete Dentures – Conventional dentures – Immediate dentures | Complete Dentures (CD): These are the right choice for patients with Edentulism, meaning they have no natural teeth left in an arch. They usually rest on the soft gum tissues and the alveolar bone underneath. Immediate Dentures: Given to the patient right after teeth are pulled, these act as a temporary replacement while the mouth heals. | They are often needed because of serious periodontal disease, widespread caries, or injury. They give important support to the face’s shape and help a patient with their chewing and speech. We work hard to make sure the final product helps the patient’s oral health. |

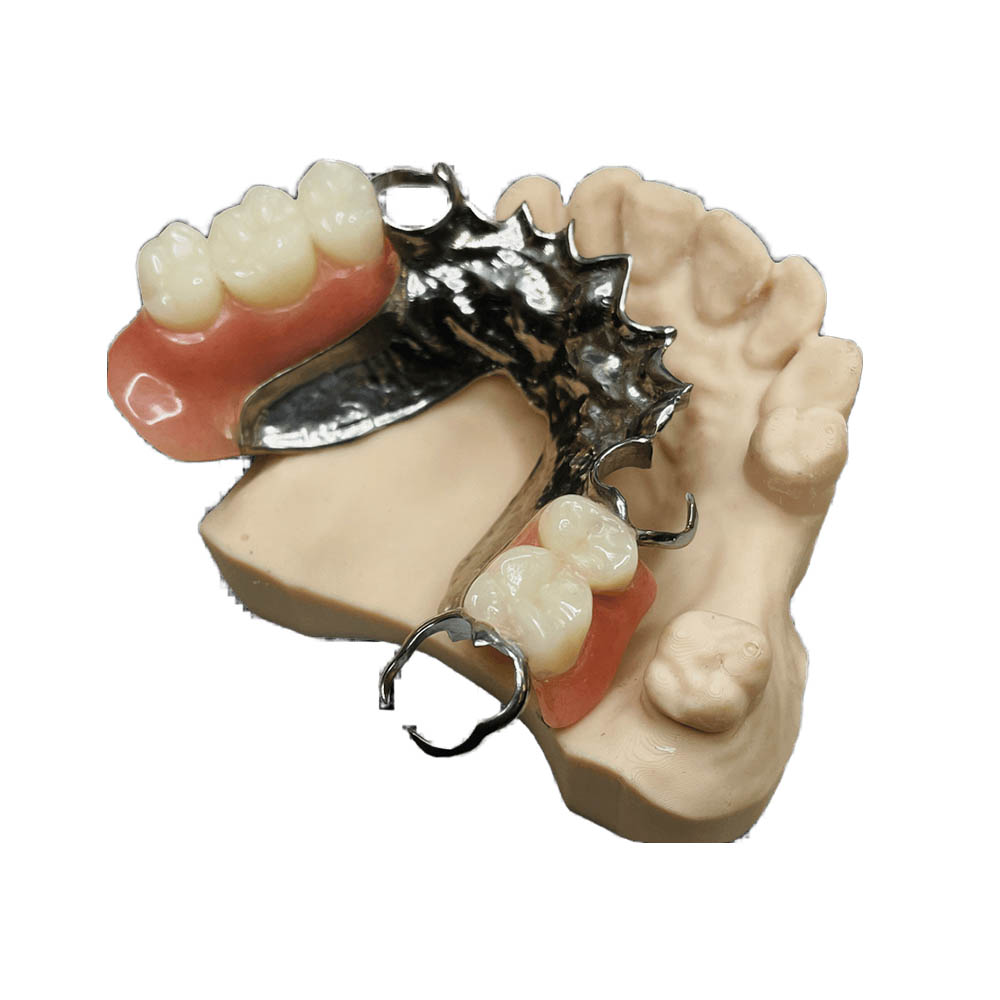

Partial Dentures – Acrylic Partials – Cast Metal Partials | Removable Partial Dentures (RPD): Made for patients who are missing some, but not all, of their teeth. The remaining natural teeth act as important anchors (abutments) to support, hold, and steady the partial denture. | RPDs are a flexible choice for many different patterns of tooth loss. A Partial Denture is perfect for patients who are missing some teeth but still have healthy ones. It is a type of Removable bridge that fills the gaps, stops other teeth from moving, and brings back a full smile. |

Flexible Dentures – Valplast dentures – Lightweight dentures | Flexible Dentures: This type is defined by the material it’s made from. They are made from modern, flexible plastics (advanced polymers), which gives them a better look and feel. The material is a special Thermoplastic resin that is almost invisible, making them a great choice for good-looking dentures. | They are recommended for certain situations, such as for patients with allergies to the usual denture materials or for those wanting something more flexible. Patients love flexible removable dentures because they are so comfortable and look great, especially for those who do not want to see metal clasps. |

Overdentures – Implant-supported dentures – Snap-in dentures | Overdentures (OD): A special type where the denture is held in place by both the soft gum tissues and a few remaining natural tooth roots or dental implants. Implant-Supported Removable Prostheses: This type, especially implant overdentures, has become very popular. They use dental implants for a much better hold and steadiness, often using special connectors like locator systems. | Carefully keeping these roots or implants is very important to save the jawbone (alveolar bone) and the sense of pressure (proprioception). This gives more steadiness and comfort to the patient than regular complete dentures. They are a great choice for patients with jawbone loss (Atrophy of the jawbone or Residual Ridge Resorption) who want more security. |

Transitional Dentures: Used as a short-term fix during long or complicated treatment plans, or while waiting for healing to finish.

Modern Technology for a Perfect Fit

Standard Materials:

- Denture Base Materials: Most complete denture bases are made from heat-treated polymethyl methacrylate (PMMA). This material is liked because it has a good mix of looks, safety, is easy to work with, and is not too expensive. PMMA usually comes as a powder and liquid that are mixed and heated, but there are also cold-cured and light-cured types.

- Denture Teeth: Denture teeth are usually made from cross-linked acrylic resins, which stick to the PMMA base. Porcelain teeth are also used because they wear down slower, but they are heavier, easier to break, and need to be held in by mechanical grips. Hybrid composite teeth are being used more and more for better looks and wear.

- Impression Materials: First impressions are usually taken with irreversible hydrocolloid (alginate) because it works well with water and is low-cost. Final impressions, which need to be more exact, use materials like zinc oxide-eugenol (ZOE) pastes, polyvinyl siloxane (PVS), or polysulfide rubber.

- Metal Frameworks: For removable partial dentures, cobalt-chromium (Co-Cr) alloys are the standard for metal frames. They provide great strength, stiffness, and long life.

The world of removable dental prosthetics is quickly changing because of new technologies, especially in advanced materials and digital making processes. These new ideas are solving the problems of the old ways, offering better results, more accuracy, and happier patients.

Advanced Materials for 3D Printing: 3D printing has completely changed the materials we can use for prosthetics:

- High-Performance Photopolymers and Hybrid Resins: New photopolymer resins are specially made for denture bases. They have a bending strength as good as or better than regular PMMA (80–120 MPa) and are tougher, hold their color better, and are clearer.

- 3D Printable PMMA and PMMA Composites: Printable PMMA-based materials and PMMA-ceramic composites are now available for denture bases and teeth. Their strength and wear are as good as heat-cured PMMA.

- Flexible Polyamide and Polyurethane-Based Materials: Flexible, nylon-based and polyurethane resins are used for 3D printing RPD frameworks and flexible dentures. These materials are very tough, don’t absorb much water, and are more comfortable for the patient.

- Ceramic- and Glass-Filled Resins: Hybrid resins with ceramic or glass fillers wear down much more slowly (up to 2x better than regular PMMA) and are harder, making them great for denture teeth.

Digital Making Processes (CAD/CAM): Using digital tools, especially for removable partial dentures (RPDs), is a major change in how things are done:

- Complete Digital Process: This usually includes mouth scanning, digital design on special CAD software, and making the item by either cutting away material (milling) or adding layers (3D printing). This can be a fully digital process or a mix where old-fashioned impressions are scanned into a computer.

- Making Frameworks: For RPD frameworks, direct metal laser sintering (DMLS) and selective laser melting (SLM) are common ways to 3D print cobalt-chromium (CoCr) alloys. Milling CoCr blocks is also common.

- Putting Base and Teeth Together: Digital tools allow for the design and 3D printing of denture bases and adding in pre-made or custom-cut teeth. Some new methods can even design both parts at the same time.

- Accuracy and Fit: Digital making, especially with SLM, shows a fit that is just as good or even better than old casting methods. The accuracy depends on the scanner, software, and finishing steps.

- Speed and Turnaround Time: Digital methods can cut the total making time by 30–50%. Some labs can deliver an RPD in 48–72 hours. The speed comes from less hands-on work and fewer steps where mistakes can happen.

- Making Custom Items for Many People: Digital tools allow for true mass customization. This means each denture can be specially designed and made without much extra cost for each one. Cloud-based design tools make it easier to produce items in different places and work together from far away.

Solving Common Patient Problems

We design our removable dentures to fix common issues and improve comfort.

- Stability: Our designs improve the suction for dentures, especially for upper dentures and difficult lower dentures.

- Health: We help you teach patients about denture care and good oral hygiene. This can prevent problems like Denture stomatitis or Candidiasis. We also offer products for patients with dry mouth, like those from Biotene.

- Comfort: We offer Soft liners for dentures. We also help with denture adjustments to prevent sores caused by dentures. We provide information on using denture glues like Fixodent or Sea-Bond.

- Speaking: Our exact fit helps patients speak with their dentures, reducing the time it takes to get used to them. We also think about the gag reflex when designing the part that covers the roof of the mouth.

Your Partner in Growing Your Practice

We are more than just a lab; we are your partner. We work with dental offices that do Full mouth reconstruction and Smile makeover cases. We support those in dentistry for older adults and those helping patients with Edentulism.

We offer support for:

- Affordable denture choices for your patients.

- Information on dental insurance and public aid for dentures.

- Fast Denture repair and emergency repair services.

- Support for mobile denture clinics that need reliable service.

- Help with Rebasing dentures and Denture reline procedures.

Partner with our skilled removable dental lab. We are a leading flexible dentures laboratory. Let us help you provide natural-looking dentures that will make your patients smile. Contact us today to get started.