Upper/Lower Cast Partial Metal Dentures for Cobalt Chrome, Titanium, Vitallium

Upper/Lower Cast Partial Metal Dentures

Istar Dental Lab: Helping Dentists with Better Solutions

As a world leader and one of China’s top five dental labs, we at Istar Dental Lab work hard to give our valued partners—dentists, dental clinics, and other labs—the best and most trustworthy dental solutions. When it comes to removable partial dentures (RPDs), picking the right material for the frame is extremely important. It directly affects how well the denture works, how comfortable the patient is, and how long it lasts.

What is a Cast Partial Denture?

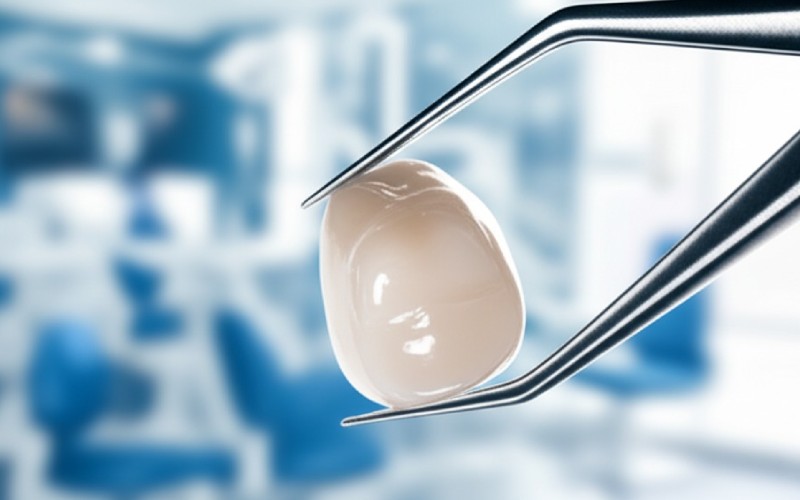

A cast partial denture is a special kind of removable dental piece. It helps fill in the space left by one or more missing teeth. This denture has a strong but thin metal frame that holds fake teeth and a pink, gum-colored base. The metal frame gives support and uses clasps to hold on to the healthy teeth next to it, which keeps the denture securely in place. Cast partial dentures are made with high-quality dental metals like cobalt chrome (cobalt chrome denture), titanium (titanium dentures), and vitallium (vitallium denture).

Comparing the Materials and How They Perform

Choosing the right metal for an RPD frame depends on a careful balance of strength, how well it gets along with the body, resistance to rust and wear, how it looks, and its overall cost. Each of these qualities is a key way to measure the denture’s performance and how long it will last.

The table below shows the key measures for each metal:

| Feature / Alloy | Cobalt Chrome (Co-Cr) | Titanium (CP-Ti Grade 4) | Vitallium (Co-Cr-Mo) |

| Yield Strength | 500–800 MPa | 480–550 MPa | ~800 MPa |

| UTS | 800–1000 MPa | 550–700 MPa | ~1000 MPa |

| Elastic Modulus | 210–230 GPa | 100–120 GPa | ~220 GPa |

| Vickers Hardness | 350–450 HV | 200–250 HV | ~400 HV |

| Fatigue Strength | 300–400 MPa ($10^7$ cycles) | 200–250 MPa ($10^7$ cycles) | 300–400 MPa ($10^7$ cycles) |

| How much metal it releases | 0.1–0.5 µg/cm²/day (Co, Cr) | <0.05 µg/cm²/day | A little lower than Co-Cr |

| How it affects living cells | Moderate (80–85% cell life) | Very little effect (>95% cell life) | Very little effect (>95% cell life) |

| Chance of allergic reaction | 1–2% (Co, Ni) | <0.1% (almost none) | <0.1% (almost none) |

| Resistance to rust/wear | Good, but can be affected by acids/fluoride | Excellent (strong TiO₂ layer) | Excellent (better protective layer) |

| Looks | Bright metal color, can change color over time | Grayish color, allows for thinner frames | Bright metal color, stays stable |

| Value for the money | High (with old-style casting) / Good (with 3D printing) | Good to Low (needs special equipment) | Good to High (a premium Co-Cr metal) |

| ISO Compliance | Exceeds Type 5 | Meets Type 4 (some Ti alloys meet Type 5) | Exceeds Type 5 |

| How it might break | Can crack, can rust | Can bend out of shape, clasps can get weak | Can crack, can rust |

| How easy it is to fix | Good (with normal soldering/welding) | Hard (needs laser welding and special methods) | Good (with normal soldering/welding) |

| How easy it is to adjust in the clinic | Easier | Harder (needs special tools and water cooling) | Easier |

Why Choose Cast Partial Dentures?

Benefits

- Tough & Strong: Made from strong dental metals.

- Comfortable: The thin frame feels more natural in the mouth.

- Stays in Place: A precise fit means they are less likely to slip or move.

- Lasts a Long Time: Can last for many years if you take care of them.

- Easy to Clean: The smooth metal surface is simple to keep clean and helps keep gums healthy.

How Our Cast Partial Dentures are Made

The way the denture is made greatly affects its final quality, fit, and cost. Istar Dental Lab uses both the old-style casting method and modern 3D printing (AM) methods, like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), to get the best results from each technique.

Traditional Lost-Wax Casting

This is an old and trusted method. It involves making a wax copy of the denture frame, covering it in a heat-proof mold material, melting the wax away, and then pouring melted metal into the empty mold.

- The Steps: This method works very well for Co-Cr and Vitallium metals. The original Vitallium formula from 1932 was made for this type of high-heat casting because it melts at a very high temperature (around 1,400°C).

- How Well It Fits: Recent studies (2023–2024) show that cast Co-Cr frames have average internal fit gaps of 60–120 μm. They can sometimes have problems with shrinking or tiny cracks, especially on the clasps.

- How Fast It’s Made: Casting takes a lot of hands-on work and has many steps. It usually takes 8–12 hours from start to finish.

- Wasted Material: Casting creates 60–80% more waste than 3D printing. This includes used mold material and harmful side-products (like dust and metal fumes). Studies also show it has a bigger environmental impact.

3D Printing (AM): SLM vs. DMLS

3D printing, especially Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), has completely changed how dental products are made. It allows for digital design and direct printing from metal powder. People often use these terms to mean the same thing, but there is a difference: SLM fully melts the metal powder, making the final part very dense and strong. DMLS might only partially melt the powder.

How It Works and What Metals Can Be Used

- SLM: This method is well-proven for Co-Cr and Ti-6Al-4V. Studies (2022–2024) show the parts are very dense (over 99.5%) and just as strong or even stronger than cast parts.

- DMLS: This is also used for Co-Cr, but the results can be less consistent with Titanium. It is almost never used for Vitallium because Vitallium needs to be fully melted to avoid becoming brittle.

Differences in the Metal Structure

- SLM-printed Co-Cr and Ti frames have a fine, organized internal structure with very few tiny holes (less than 0.5%).

- DMLS parts can have a more mixed-up structure, with areas that aren’t fully melted and more leftover tiny holes (up to 2%). This can affect how well they resist breaking and how well they work in the mouth long-term.

How Accurate and Well They Fit

- Better Accuracy: Recent lab studies (like one in 2023 from the University of Zurich) show that SLM makes more accurate RPD frames. The average difference from the digital plan is only 30–50 μm for Co-Cr, while DMLS is 60–90 μm. SLM frames from EOS and Renishaw machines are always better than cast frames in how well they fit.

- Edge Fit: 3D-printed frames have fewer internal holes and a more reliable fit at the edges than cast frames.

Surface Finish and Final Steps

- Surface Smoothness: SLM parts usually have a smoother surface right after printing (Ra 6–10 μm for Co-Cr) compared to DMLS (Ra 10–18 μm). This means less finishing work is needed. However, both still need to be polished to a very smooth finish for use in the mouth (Ra < 0.5 μm).

- Extra Steps: SLM-printed Co-Cr and Ti frames often need a heating process to remove stress and make them less brittle. DMLS parts might need even more heat treatment. Removing the support structures used during printing is usually easier with SLM.

Internal Flaws and Best Settings

- Controlling Flaws: Scans show that SLM frames have fewer internal holes and fewer spots where the metal didn’t melt together properly, especially when using the best machine settings. DMLS frames are more likely to have trapped gas bubbles and spots that aren’t fully melted.

- Best Settings: For Co-Cr, the best SLM settings (on EOS M290 and Renishaw AM400 machines) are: laser power 250–350 W, scan speed 900–1200 mm/s, layer thickness 30–40 μm, in an argon gas environment. For Ti-6Al-4V, thinner layers and faster speeds are usually better.

Why Dental Professionals Choose Us

- Made by Experts: Every cast partial denture is carefully made for a perfect fit by trained dental technicians.

- Many Choices: We offer a full range of options for every situation: cobalt chrome denture, vitallium denture, and titanium dentures.

- Fast and Reliable Service: We can help dental hospitals, clinics, and labs of any size.

- Safe Materials: We only use dental metals that have been tested and approved.

- Helpful Support: Our team understands how to replace teeth and can help you with both simple and difficult cases.

Ready to Serve

When you need cast partial denture solutions for your patients or lab, you can count on us for expert work and reliable products. Pick the metal that fits your needs—cobalt chrome denture, vitallium denture, or titanium dentures—and help your patients get smiles that last!

If you need more information or have a special case, just contact us. Our team knows how important it is to find the right cast partial denture for every person.