Upper/Lower Partial Dentures

Your Top Partner for Upper and Lower Partial Dentures

Welcome to our dental lab service. We are your reliable partner for making top-quality dental devices. We work with General Dentist offices, dental hospitals, and clinics of all sizes. We are a main support for other labs that need help. Our focus is on making the best upper partial dentures and lower partial denture solutions for your patients.

We think clear communication is important. Our aim is to be a real partner to every Prosthodontist and dental expert we work with. We give you all the key details and information you need for each case. This helps you pick the best option for your patients, from a simple flipper denture to more difficult upper and lower dentures.

Why Choose Our Lab Service?

When you work with us, you get more than just a product. You get a committed team.

Expertise: Our Dental Technician team is certified by The National Board for Certification in Dental Laboratory Technology. We follow standards from the American Dental Association (ADA) and the American College of Prosthodontists (ACP).

Clear Communication: We share information in a clear way, so the advantages are easy to understand. We focus on what makes our service great and how we solve your problems.

Full Range of Services: We make every kind of removable partial denture (RPD). This includes the popular maxillary partial denture and mandibular partial denture. We also help bring back a patient’s smile and improve their quality of life with dentures.

Removable Partial Dentures (RPDs)

Removable Partial Dentures (RPDs) are still a key part of making dental replacements, giving a flexible and often affordable option for patients missing some teeth. At Istar Dental Lab, we use modern design ideas and making methods to produce RPDs that focus on patient comfort, steadiness, and long life.

Clinical Indications and Contraindications

RPDs are suggested for patients with missing teeth who can’t or don’t want to get fixed bridges or implants. They are especially good for cases with large gaps of missing teeth, weak supporting teeth, or limited budgets. Reasons not to use them include serious gum disease, not enough supporting teeth, or patients not keeping them clean.

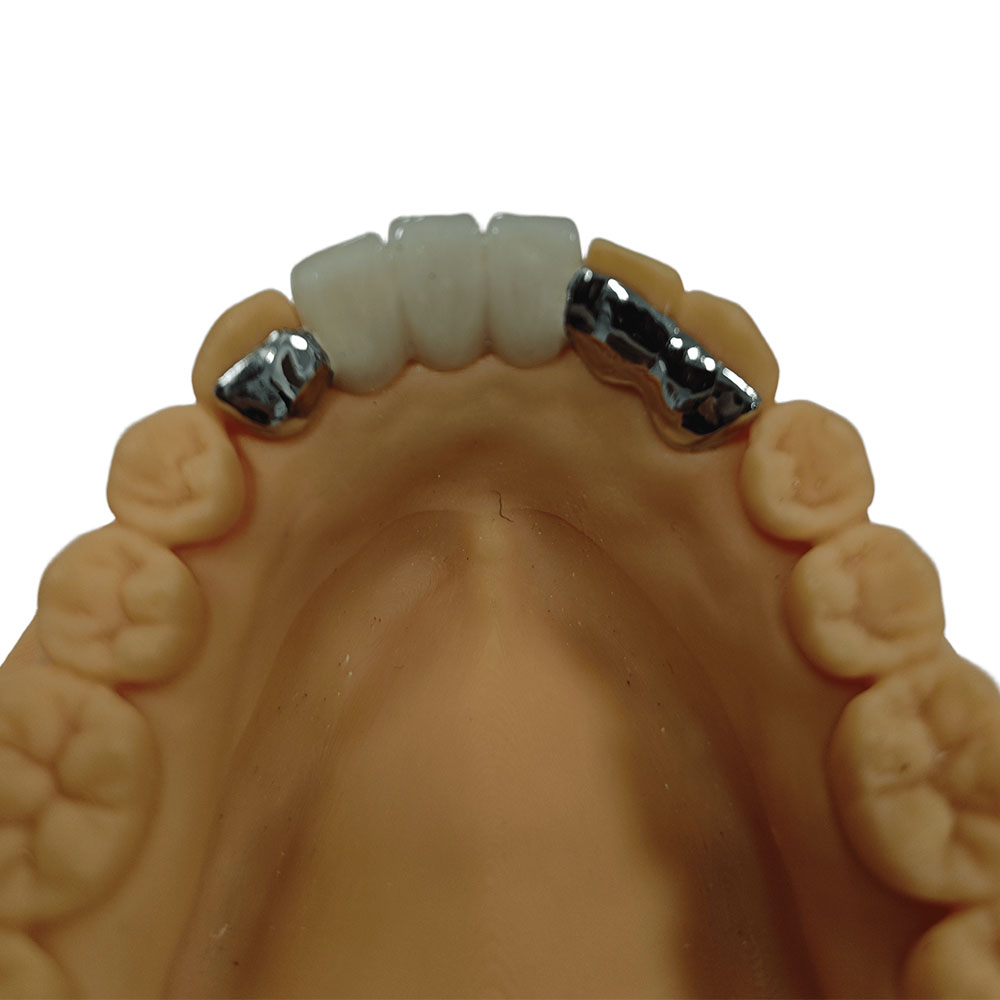

Our Denture Products at a Glance

We have many different choices for upper partial dentures and lower dentures. This table shows some of the choices you can offer your patients.

| Denture Type | Common Materials | Key Components | Best For Patients Who Need… |

| Cast Metal Partial Denture | cobalt-chromium (Co-Cr) alloys | Metal framework, Major connector, Denture clasps (I-bar clasp, C-clasp), Rests (occlusal, cingulum, incisal) | great stiffness, strength, and spreads out bite force very well. These frames are very long-lasting and give steady support for the denture. |

| Flexible Partial Denture | nylon-based resins | Flexible denture base, Gum-colored clasps, Artificial teeth (acrylic) | better comfort, looks, and fit at the beginning, especially in the first 6–12 months after they are put in. Because they are flexible, the clasps are hard to see, which is nice for patients who care about looks. |

| Acrylic Partial Denture (Flipper) | Acrylic resin, Wrought wire clasp | Denture base, Minor connector, Artificial teeth | A low-cost or temporary partial denture. Also called a Nesbit partial or spoon denture. Good for use after a tooth extraction. |

| Combination Partial Denture | A mix of metal and flexible materials | Precision attachment partial parts, Semi-precision attachment partial parts, guiding planes | A custom option that is both strong and looks great. It holds the denture in place very well. |

Management of Bone Resorption and Soft Tissue Irritation in Lower Arch RPDs

The lower jaw has special problems because its outer bone is thinner and takes more pressure from chewing, which makes the bone shrink faster (up to 0.4 mm/year after a tooth is removed). Istar Dental Lab handles these problems by:

Material Selection: While flexible bases can lessen soreness at first, hard frames (Co-Cr, PEEK, 3D-printed titanium) are very important for long-term steadiness and less bone loss because they spread out pressure better.

Stress-Breaking Attachments: Adding stress-breaking attachments greatly lowers the up-and-down and side-to-side pressure on the jawbone ridge. This leads to a 35% decrease in the speed of bone loss over five years.

Implant-Assisted RPDs (IARPDs): Putting two or more thin implants in the front area of the lower jaw can cut the speed of bone loss in the back of the jaw by half, giving better support and steadiness.

Precision Fabrication: Our digital impression and CAD/CAM methods make sure the base fits perfectly, lowering the chances of mouth sores by up to 40% compared to older methods.

Patient Education: We stress how important it is to teach patients about mouth cleaning and follow-up visits, which can lower gum sores by 50% and yearly bone loss by 25% with regular checkups every 3–6 months.

The Process: From Your Clinic to Our Lab

We use modern tools to make perfect upper and lower dentures. Our way of working is simple and fast.

Consultation and Design: You send us the case details. This includes notes on preparing the supporting teeth and the bite you want. We use this to plan and design the perfect mandibular denture or upper dentures.

Impressions and Fabrication: The old way of making RPDs has many lab steps, including wax-up, investing, and casting. While it’s a proven method, it can sometimes have size errors. But digital methods are changing how RPDs are made:

Digital Impressions: An oral scanner takes the place of regular mold materials, greatly cutting down on appointment time (from 15–25 minutes to 5–10 minutes) and making it more comfortable for the patient, especially for those who gag easily.

CAD/CAM Design: Computer design helps create an exact frame, improving how it holds, supports, and stays steady. This digital way of working cuts design time by up to 60% and making mistakes by 20–30% compared to doing it by hand.

3D Printing: This building-up process allows for printing RPD frames directly from computer-friendly resins or metals, making sure they fit great and wasting less material.

Finishing and Delivery: We finish the denture and send it to your clinic. It will be ready for the fitting and any small adjustments.

Alternatives and Advanced Solutions

We know a removable partial denture is just one option. We can also help you with other choices. This lets you give your patients full care.

Fixed Partial Dentures (FPDs) / Dental Bridges

Fixed Partial Dentures (FPDs), also known as dental bridges, give a permanent option for replacing missing teeth, with great steadiness, use, and looks. Istar Dental Lab is an expert in making FPDs that blend in perfectly with the natural teeth.

Structural Components and Material Options

FPDs are made of abutment crowns (placed on natural teeth or implants) and pontics (fake teeth replacing the missing ones), all joined together as one piece. Choosing the right material is key to balance strength and looks:

Porcelain-Fused-to-Metal (PFM): An older choice that gets its strength from a metal base and its looks from a porcelain layer on top.

All-Ceramic Materials:

Zirconia: Known for being very strong and hard to break. Solid Zirconia FPDs show much higher breaking points (mean >2000 N) and more than 90% last through repeated chewing pressure. While older types had limits on how good they looked, see-through Zirconia (5Y-TZP) now offers better looks.

Lithium Disilicate (Emax): Liked for being very see-through and easy to match to tooth color, fitting in perfectly with other teeth. It always shows color difference values of less than 2.0, which makes it very hard to spot. But, it is not as strong (mean 900–1200 N) as zirconia, and it is more likely to get tiny cracks from temperature changes and chewing.

Clinical Considerations for Arch Locations

The material and design you choose for FPDs depends on where it is in the mouth and the bite pressure:

Posterior Bridges: Zirconia is often picked for its great strength and because it’s hard to break in areas that get a lot of chewing pressure. While Zirconia with a porcelain layer can chip (up to 18% at 5 years), solid Zirconia shows much lower chipping rates (<5%).

Anterior Bridges: Lithium disilicate is perfect for front areas where looks are most important because it is very see-through. But, you must pay close attention to the size of the connectors (height and width ≥4 mm), because lithium disilicate is more affected by connectors that are too small.

Cementation Protocols: Using a strong resin glue greatly improves how well lithium disilicate FPDs resist breaking and how long they last. For zirconia, while the type of glue matters less, using primers with MDP makes the bond stronger.

Advanced Biomaterials for Abutment Tooth Longevity

Similar to RPDs, how long FPDs last is directly tied to the health of the supporting teeth. We use the same modern material plans to make sure they last a long time, including self-healing composites, germ-killing coatings, and tissue-growing therapies.

Implant-Supported Partial Dentures

Implant-supported partial dentures are the top choice in modern tooth replacement, giving unmatched steadiness, use, and protection of the jawbone. Istar Dental Lab gives full support for fixed and removable implant-supported dental devices.

Configurations and Protocols

Implant-supported partial dentures can be grouped into:

Fixed Bridges on Implants: These dental devices are permanently glued or screwed onto dental implants, giving a very steady and natural-feeling replacement.

Removable Overdentures: These dental devices are held in by implants but can be taken out by the patient. They offer better steadiness than regular RPDs and are easier to clean.

Our methods focus on being exact and reliable:

Surgical Planning: Using modern imaging (CBCT) and AI-powered image review, we help with exact implant placement, planning for bone thickness and the shape of the area.

Restorative Protocols: We support both regular and immediate loading methods. With immediate loading, a temporary replacement is put in right after implant surgery, which has big benefits for the patient.

Material Choices

Materials for implant-supported dental devices are similar to those for FPDs, with zirconia and lithium disilicate being popular choices for fixed bridges, and acrylic or advanced polymers for overdenture bases.

Advantages

Bone Preservation: Implants activate the bone around them, stopping the bone loss that often happens with regular dentures.

Superior Function: Patients find their chewing is much better (35% improvement over RPDs) and they can eat a wider range of foods.

Enhanced Aesthetics and Comfort: Fixed implant bridges look and feel the most natural, with very few speech problems or soreness.

High Patient Satisfaction: Implant-supported partial dentures always get higher scores from patients on things like chewing, comfort, and mental well-being.

Supporting Your Patients

We help you give the best care. We can give you info on many topics to help your patients. This includes:

Denture Care: How to use a denture brush, denture cleanser, and denture adhesive. We also give tips on plaque removal and avoiding tartar buildup.

Patient Experience: We can give info on the getting-used-to period, how to deal with sore spots, and what to expect when eating with partial dentures. This helps make patients happier.

Health Concerns: We know about problems like denture stomatitis, partial edentulism, and bone resorption. Our designs for upper partial dentures keep these things in mind.

Partner With Us Today

Let our lab be your first choice for all removable prosthodontics. We are experts at making every kind of lower partial denture and maxillary partial denture. We are ready to help you give great care.

Contact us to send your first case. Let’s work together to make great-looking and useful upper and lower dentures for your patients.