Crown and Bridge

As one of the top five dental labs in the world, Istar Dental Lab works with many different clients, including dentists, dental clinics, hospitals, and other dental labs who need dependable, modern dental products. Our work is carefully planned to meet the highest world standards, making sure every piece we make is precise, made quickly, and looks great.

01.

Scale and Efficiency

Our large-scale work and modern digital tools give us great efficiency and value. This lets us offer good prices without cutting back on quality. We finish cases for crowns, bridges, and other dental work 30–50% faster than the old ways. This speed is very important for our partners around the world, helping them see their patients sooner.

02.

Technological Leadership

We are always investing in the newest CAD/CAM, 3D printing, and AI technology. Using digital scans and CAD/CAM milling cuts down on gaps at the edges from 100–150μm (with manual methods) to an amazing 30–50μm. This makes sure restorations fit perfectly and patients are comfortable.

03.

Global Reach with Local Understanding

We work with clients all over the world, but we also understand what different regions need. This helps us offer custom solutions and quick service. We see our clients as partners, not just customers. We focus on clear communication, easy digital workflows, and helpful support to build lasting relationships that are good for everyone.

What We Make: Expert Crowns and Bridges

At Istar Dental Lab, we use our deep knowledge of the market to offer a wide variety of products made with the best materials you can get.

- Full Contour Crowns: Single crowns made for the best strength and looks.

- Dental Bridges: Dental work with multiple units to replace missing teeth, bringing back function and appearance.

- Veneers: Thin, custom-made shells that cover the front of teeth to make smiles look better.

- Inlays and Onlays: Partial pieces used to fix damaged or decayed teeth, which saves more of the natural tooth.

- Implant-Supported Restorations: Custom abutments and crowns/bridges made to fit perfectly with dental implants for strong solutions that last a long time.

- Temporary Prosthetics: High-quality temporary restorations for patients who need them right away.

- Diagnostic Wax-ups and Models: Precise models for planning treatment and talking with patients.

10+ years of manufacturing experience

10000 square meters of modern dental lab

300 technicians with various advanced machines

Our Production Process: A Digital Journey

Our production process shows our dedication to being great at digital work, making sure every step is precise, fast, and consistent.

We get very accurate digital scans from our partners’ intraoral scanners, so we don’t need physical models. This speeds things up.

After that, our expert team reviews the digital case to make sure we understand all the clinical needs and what the patient wants it to look like.

Using top CAD software, our skilled designers, helped by AI, create precise 3D models of the restoration. AI helps find the edges and design the shape and bite, making the design phase much faster.

Then the design is approved, and the best material (like zirconia, lithium disilicate, or PFM) is chosen based on the case and what our partners ask for.

The design is sent to CAM software, which finds the best layout for many restorations on one block of material (nesting) and creates exact instructions for the milling machine or 3D printer.

- Milling: High-precision machines carve the restoration from a solid block of material.

- 3D Printing: For things like temporary crowns, models, or surgical guides, our 3D printers build the piece layer by layer.

Milled zirconia pieces are heated in a special oven to make them strong and dense. 3D-printed resins are hardened with UV light.

Our technicians carefully finish and polish the restoration, making sure it has smooth surfaces, the right shape, and looks great. This can include adding color and glaze to make it look natural.

Every restoration goes through tough quality checks. AI systems check for tiny flaws and fit, along with a careful check by our experienced quality team.

The finished piece gets one last full check to make sure it meets all the requirements and our high standards before it is packed safely.

Using fast shipping networks, the finished restoration is sent out for on-time delivery to our partners all over the world.

Our Quality Control: Our High Standards

Quality is the foundation of Istar Dental Lab’s good name. Our complete quality check system is made to meet and beat the highest world standards, making sure every restoration we make is of the best quality.

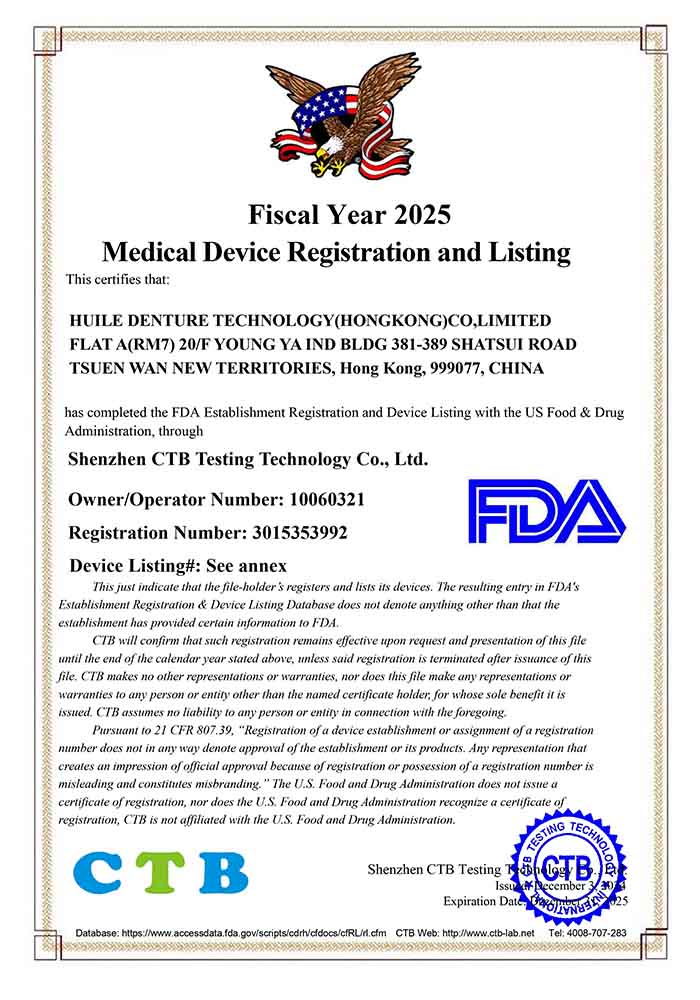

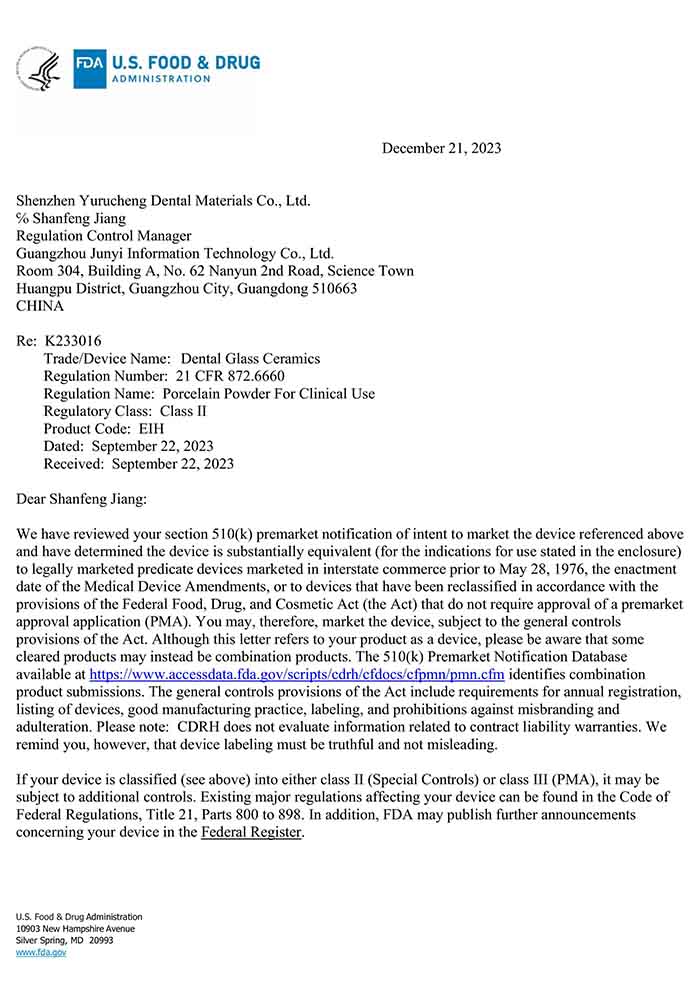

Istar Dental Lab has a strong system for quality that follows all the rules for global medical devices.

- FDA Compliance (21 CFR Part 820): For our partners in the United States, we follow the Quality System Regulation. We are ready for the future update to match ISO 13485.

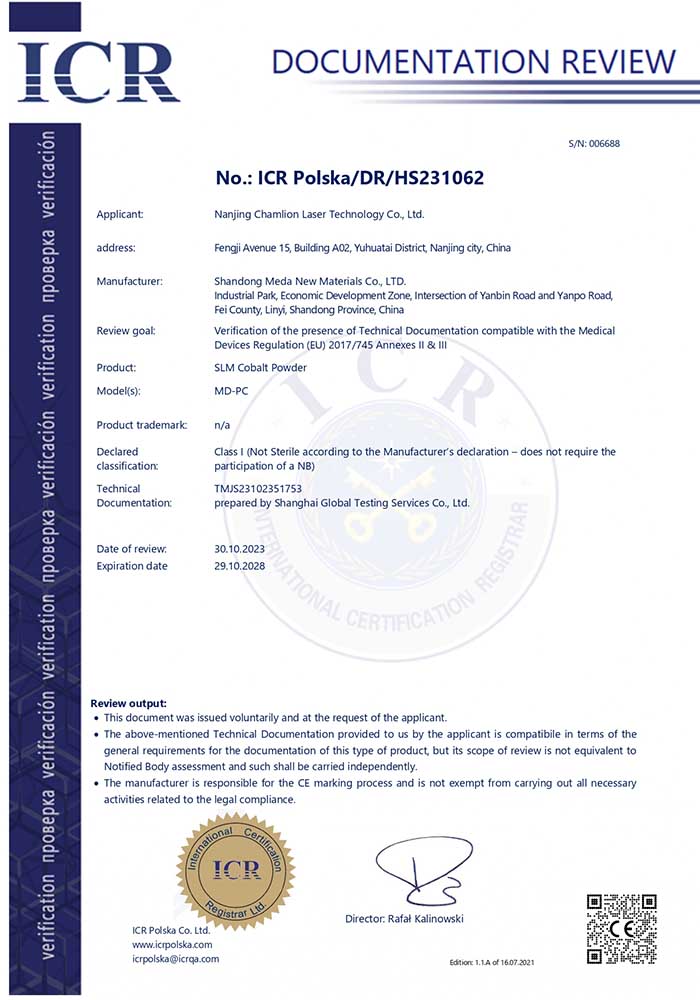

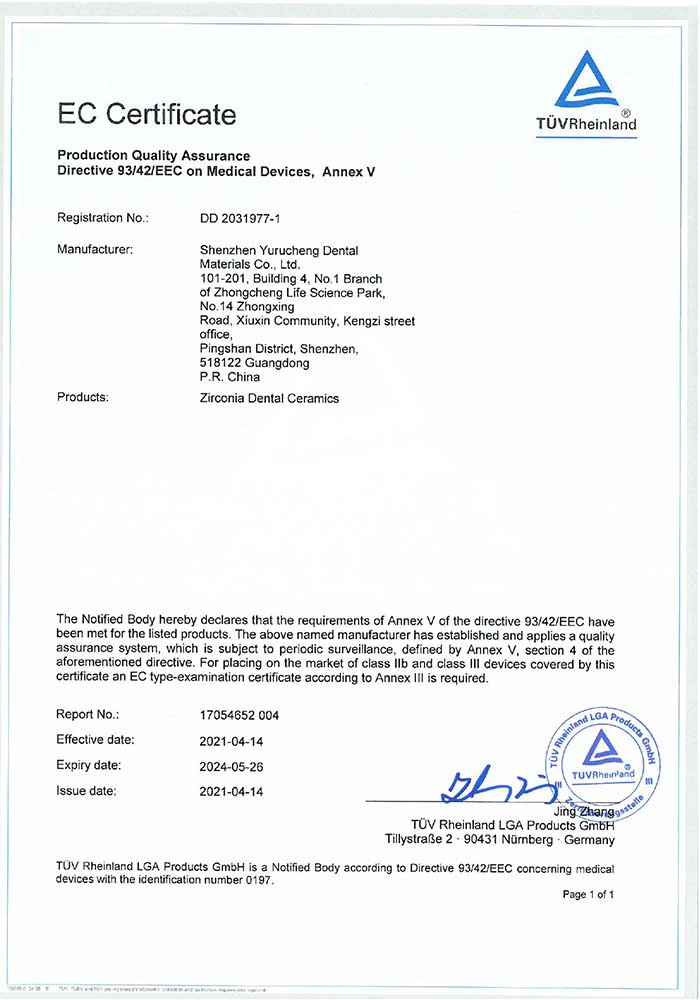

- EU Medical Device Regulation (MDR) (Regulation (EU) 2017/745): For our European partners, we meet the tough rules of the MDR. Our custom-made devices come with a document saying they meet the standards.

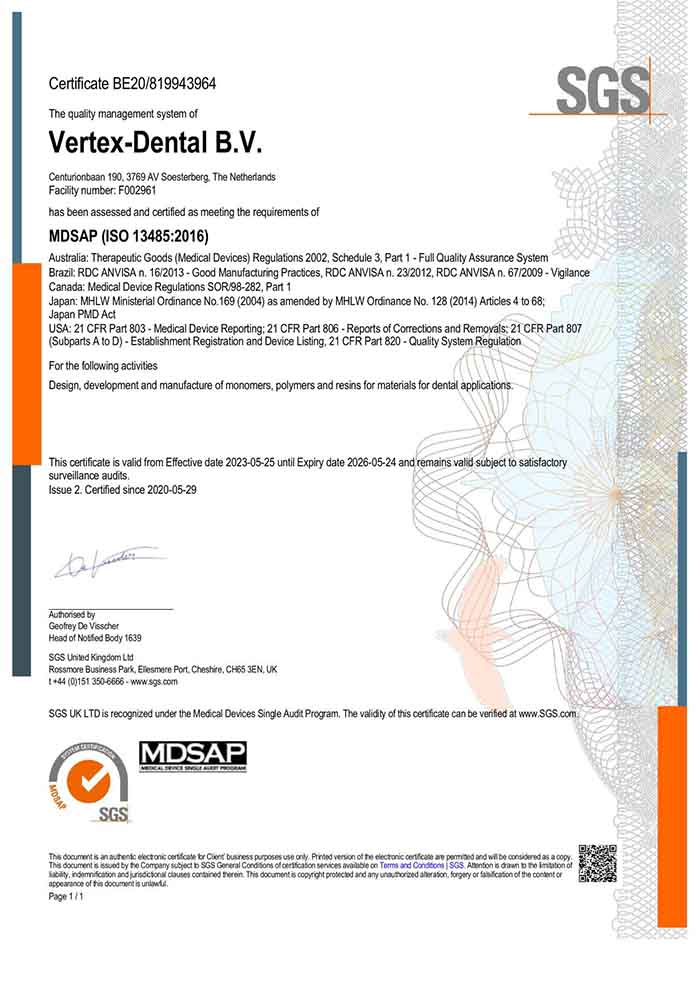

- ISO 13485:2016 Certification: We are certified for ISO 13485:2016, the world standard for quality systems in medical devices. This shows we are serious about quality.

We have a strict system to track every material we use, from the batch it came from to the final piece for the patient. This helps us take responsibility and act quickly if there is ever a problem.

- All our main making processes, like CAD/CAM milling, 3D printing, and sintering, are carefully tested and approved. We have proof that our process works the same way every time.

We do multiple quality checks during production. This includes automatic checks by AI for fit and surface, along with careful manual checks by our skilled technicians.

Before packing, every piece gets a full final check to make sure the shape is right, it looks good, it fits, and it meets all the requests.

Our Materials: Strength and Beauty

We choose our materials based on what works best clinically, looks great, and is safe for the body, keeping up with what’s new in the market:

- Zirconia:

- Monolithic Zirconia: For amazing strength and long life, great for back crowns and bridges.

- Layered Zirconia: Mixes strength with great looks by adding layers of porcelain.

- High Translucency Zirconia: For front teeth where letting light pass through like a real tooth is important.

- Lithium Disilicate (Emax): A favorite for its beautiful look and how it can be used in many ways, especially for veneers and front crowns.

- Porcelain-Fused-to-Metal (PFM): A classic choice that offers a mix of strength and good looks, especially for long bridges.

Certificates Istar Have Obtained

We’re a top-5 3D dental lab in China, CE & FDA & ISO certified, NADL member. 10 years of quality restorations, implants, and dentures. Your trusted dentistry partner.

What Our Doctor’s Say

"The porcelain fused to metal crowns from Istar Dental Lab are outstanding. Their lab offers reliable turnaround times, and the quality control process ensures every restoration meets high standards."

"Istar Dental Lab consistently delivers exceptional zirconia restorations. The crowns are aesthetic and fit perfectly, enhancing patient satisfaction. Their attention to detail is unparalleled."

"The use of translucent zirconia by Istar Dental Lab has transformed my practice. The crowns are available in shades that match natural teeth, making them an ideal choice for anterior restorations."

"Istar Dental Lab provides high-quality crown and bridge restorations at competitive prices. Their metal-free options, like e.max and zirconia, offer both durability and esthetics."

"The PFM dental crowns from Istar Dental Lab have excellent fit and flexural strength. Their professional workflow ensures consistency in every case."

Experience faster turnaround times with our cutting-edge technology

Latest from Blog

Explore dentistry trends, dental lab insights, digital dentistry updates, and tips for dentists on implants, crowns, restorations, and dental technology.

How Do Dentists Help the Community? Beyond the Chair and Into Everyday Life

When most people think about dentists, they picture a bright light, a reclining chair, and someone asking questions while…

How Do You Get Rid of Numbness From the Dentist? A Real-World Guide

Walking out of the dental office with half your face asleep is… not the vibe. You’re drooling a little,…

How Do I Choose a Dentist?

Choosing a dentist isn’t like choosing a new café. You’re literally handing someone sharp instruments, your health, your money,…