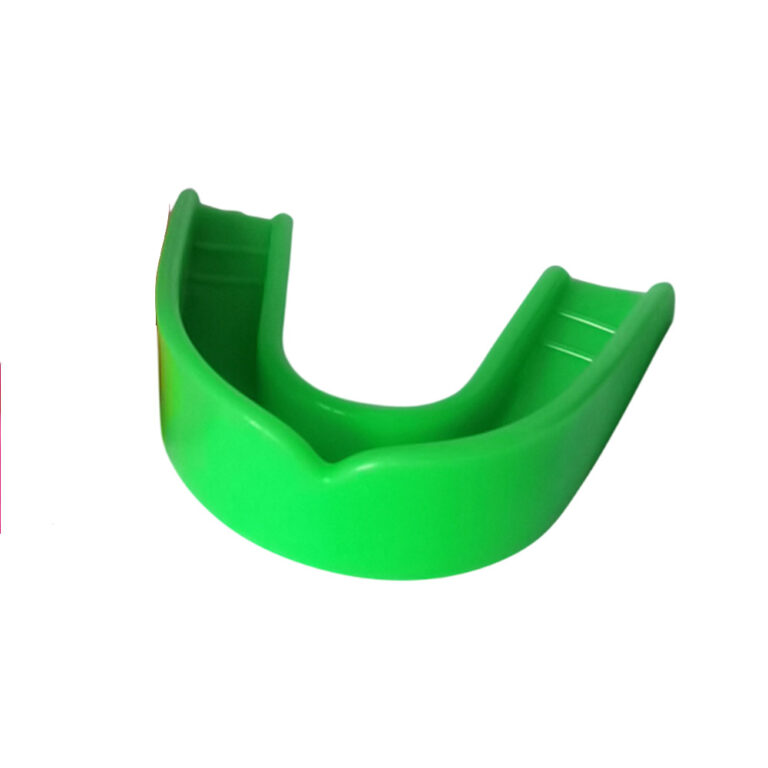

Custom Sports Mouth Guard

Custom Sports Mouth Guard Manufacturer

At Istar Dental Lab, a top dental laboratory, we know how important modern mouth protection is for keeping athletes safe. Our product is made just for you. It’s the first choice for dentists and clinics who want the best safety and quality for their athletes, patients, and customers. This isn’t just any mouthguard—it’s a custom athletic mouthguard built for top performance.

A custom sports mouth guard is a protective mouth device made for one person. It’s carefully shaped to fit an athlete’s exact teeth and mouth structure. These devices are usually made from special heat-molded plastics, mainly ethylene-vinyl acetate (EVA), or other modern plastic materials. Their main job is to stop or lessen injuries to the mouth, teeth, and face that happen during sports. Unlike one-size-fits-all options, custom mouth guards offer an unbeatable fit, stability, and comfort. These things are essential for the best protection and for making sure athletes actually wear them.

Why Our Custom Sports Mouth Guards Are Special

Making custom mouthguards for sports is what we do best. Here’s why dentists and dental clinics of all sizes choose us:

Fit and Retention

Custom-made mouth guards, usually made with ethylene-vinyl acetate (EVA) using a vacuum or pressure-layering method, always show a better fit and stay in place better. Measurements using modern tools like micro-CT and pressure mapping show that custom guards have a tiny gap of less than 1 mm between the tooth and the guard.

Comfort and User Satisfaction

In surveys, athletes consistently give custom guards the highest scores for comfort (average VAS score of 8.5/10), with boil-and-bite at 6.2/10 and stock guards at 3.8/10. Feedback often points out that custom guards reduce sores in the mouth and the gagging feeling that often come with poorly fitting stock or boil-and-bite guards. Feeling uncomfortable is a main reason people don’t wear them, especially stock guards, so great comfort is key to making sure they are worn all the time.

Protective Efficacy (Impact Attenuation)

Drop tests and computer models (FEM) clearly show the better shock-absorbing abilities of custom mouth guards. These guards lower the main force of an impact by 40–60%. Custom guards, especially those with two layers of EVA (4–5 mm thick), offer better shock absorption. Long-term studies with over 2,000 athletes (2019–2023) show that custom guards are linked to a major drop in face and mouth injuries (Relative Risk [RR] 0.3–0.5) compared to boil-and-bite (RR 0.6–0.8) and stock guards (RR 0.8–1.0).

Speech Clarity and Breathing Difficulty

Tests show that custom mouth guards have very little effect on how clearly a person can speak (less than 5% change), mostly because the part covering the roof of the mouth is shaped perfectly. In the same way, breathing difficulty, measured with a spirometry test, is lowest with custom guards (less than 3% change in FEV1), medium with boil-and-bite (5–8%), and highest with stock guards (10–15%). Some stock guards have been seen to block the airway in up to 20% of users, showing why a custom fit is so important for easy breathing during sports.

Cost-Effectiveness and Economic Impact

While custom mouth guards cost more at first (usually $150–$400 USD) than boil-and-bite ($15–$40) and stock ($5–$15) options, a full look at costs and benefits shows they are a better deal over 3–5 years. This is mainly because of much lower injury rates and the related drop in dental treatment costs, saving an estimated $1,200–$2,500 per athlete over five years. U.S. insurance claim numbers from 2018–2022 show that athletes using custom guards make 60% fewer claims for dental injuries than those using other types.

Durability and Material Breakdown

Tests that simulate aging and wear (using ISO 10271 rules) show that custom EVA guards keep over 90% of their shape and strength after 12 months. In contrast, boil-and-bite guards weaken to 70–80% and stock guards to 50–60% in the same time. Custom guards are better at resisting peeling and tearing, lasting an average of 2–3 years, which is much longer than the 6–12 months for boil-and-bite and less than 6 months for stock guards. Also, the growth of germs is lowest in custom guards because of their better fit and less porous material, which helps with better mouth hygiene.

Compliance and Usage Rates

Studies watching athletes (n=1,200, 2020–2023) report that 85–95% of them wear their custom guards, compared to 60–75% for boil-and-bite and less than 40% for stock guards. The main reasons people don’t wear stock guards are discomfort and a poor fit. The fact that more people wear custom guards means they get more protection in real games. Because of this, big sports groups like the NCAA and World Rugby are starting to require custom guards for high-risk sports, pointing to their proven higher usage and lower injury rates.

User Demographics and Customization

Custom mouth guards are especially helpful for children and people with braces. Boil-and-bite and stock types often can’t fit well around a mix of adult and baby teeth or braces, leading to a poor fit and higher injury risk. A custom-made guard allows for a perfect fit around changing teeth and braces, providing constant protection and comfort. While some companies like Shock Doctor, SISU, and OPRO have created hybrid models (like at-home custom fitting with digital scans), there is not much long-term data on how well they perform.

Long-Term Health Outcomes

Studies lasting five years or more (n=800) show that athletes who always use custom mouth guards have lower rates of jaw joint (TMJ) problems and bad bites. This is because a perfectly fitted guard provides a better bite balance and reduces stress from clenching or grinding.

Key Features

| Feature | Details |

| Material | High-quality EVA, medical-grade plastics, BPA-free, safe for the body |

| Fit Type | Custom fit from a dental mold or 3D scan |

| Construction | Single-layer, dual-layer, or multi-layer for extra protection |

| Thickness Options | Several options, based on the person’s needs and sport type |

| Customization | Choose team colors, add logos, pick designs |

| Certifications | FDA approved, CE certified, meets global dental standards |

| Use | Made for football, basketball, boxing, martial arts, hockey, rugby, lacrosse, and more |

Our Modern Manufacturing and Digital Process

The way custom sports mouth guards are made has seen a big change with the arrival of digital technology. At Istar Dental Lab, we use these modern processes to deliver perfectly made solutions to our partners around the world.

Moving to Digital Impressions

The industry is quickly moving from old mold-taking methods (using alginate or silicone) to digital mouth scanning. Devices like the 3Shape TRIOS, iTero Element, and Medit i700 are now common. Studies in journals like the Journal of Prosthetic Dentistry (2023) confirm that digital scans make patients more comfortable, get rid of errors from material warping, and allow for instant data transfer to dental labs. This digital change is a key part of modern, efficient dental lab work.

CAD/CAM Integration

Computer-Aided Design (CAD) software, like exocad DentalCAD and 3Shape Dental System, is often used to design custom mouth guards with great accuracy. This gives us careful control over important details like thickness, bite coverage, and fit. New systems are starting to use AI to suggest designs based on bite analysis and a patient’s risk factors, making the mouth guard’s shape even better for protection and custom fit.

3D Printing Methods

3D printing is used in two ways to make custom mouth guards:

- Direct Making: Body-safe flexible materials, like KeySplint Soft by Keystone Industries, allow for the direct 3D printing of custom mouth guards. This is a fast and very precise method.

- Making Molds: More often, 3D printing is used to create very accurate models from digital scans. These models are then used for traditional pressure or vacuum-forming methods, which are often chosen for their better shock absorption in high-impact sports. SLA and DLP printers (like Formlabs Form 3B, Asiga MAX) are most common because of their high detail and ability to work with many dental materials.

Accuracy and Consistency

Digital processes offer unmatched accuracy and consistency. Studies (like in the International Journal of Computerized Dentistry, 2024) show that mouth scanners are accurate to within 50 microns. 3D-printed mouth guards are typically less than 100 microns different from the digital design, making them more accurate than guards made from old-style molds.

Process Speed and Turnaround

Using a digital process greatly cuts down on production time. Old mold-based methods usually take 5–7 days, but digital processes can shorten this to just 24–48 hours. Automatic and batch printing also speeds things up, letting dental labs handle more orders efficiently.

Cost-Effectiveness

Although the first purchase of digital scanners and 3D printers can be expensive ($10,000 to $50,000 USD), the cost to make one guard can drop below $20. This is much lower than the $50–$100 for outsourced or traditional methods. Reports from industry leaders like Kulzer and Dentsply Sirona show a typical Return on Investment (ROI) within 12–18 months for busy labs and clinics.

Environmental Impact

Digital processes help make manufacturing more eco-friendly by cutting down on waste (like no stone models and less shipping). However, there are still concerns about recycling the plastic resins and the energy used by 3D printers. Studies from 2023 show a 30–40% smaller carbon footprint compared to old methods, especially when using recyclable materials and local production.

Automation and AI

The future of making custom mouth guards is becoming more automated and driven by AI. New systems (like uLab Systems, Dentsply Sirona DS Core) are testing AI-powered design, where software suggests mouth guard shapes based on scans and a person’s sports activities. Some systems connect directly with clinic management software, creating a fully automatic order-to-delivery system that makes the whole process simpler.

Clinical Results and Case Studies

Recent clinical trials (from the Journal of the American Dental Association, 2024) report better fit, stability, and patient happiness with digitally made mouth guards. Case studies from companies like Straumann and Zirkonzahn show a big reduction in adjustment time in the dental chair (by 60–80%) and fewer remakes, leading to a better experience for both the clinic and the patient.

Regulatory and Material Updates

The number of FDA-cleared 3D printable materials for mouth devices (like KeySplint Soft, NextDent Ortho Flex) is growing, with new options offering better flexibility, tear resistance, and safety. The ISO 20795-2:2023 standard is now often used to ensure the quality of digital mouth guard production, making sure these advanced materials and processes meet high safety and performance levels.

Comparing Technologies

While direct 3D printing of mouth guards is becoming more popular, guards made on 3D-printed models using pressure forming are often still the best choice for high-impact sports because they absorb shock better. Mixed processes, which combine digital scanning with 3D-printed models for pressure forming, are common in top-level sports dentistry, used by pro teams (like Team GB, NFL teams) to get the best protection.

Future Directions

Research is looking into multi-material 3D printing (like with the Stratasys J5 DentaJet) for mouth guards with different hardness zones for even more customized protection. Cloud-based design platforms are also appearing, making it easier for dental teams to communicate and work on designs from different locations. New companies (like GuardLab, Proform 3D) are trying out direct-to-consumer digital processes, possibly using smartphone scans to make it easier for everyone to get a custom guard.

How Our Custom Made Mouthguard for Sports Works

Making and using a custom sports mouth guard successfully depends on carefully following proven clinical steps. At Istar Dental Lab, we focus on these detailed steps to get the best results for our dental partners’ patients.

Step-by-Step Clinical Process

The standard process for making a custom sports mouth guard has several stages for accuracy and a personalized fit:

- Patient Check-up and Risk Analysis: This first step includes a full dental exam, a review of medical history, and a look at the athlete’s sport, how intense it is, and the related injury risks. A bite analysis is key to finding any existing bite problems.

- Taking an Impression: This can be done with traditional alginate or silicone molds, or more commonly now, with a digital mouth scanner.

- Getting an Accurate Bite: This is a key step to record how the athlete’s teeth come together. For contact sports, a “centric relation” bite is often best to spread out impact forces evenly.

- Lab Creation: Using the molds or digital data, the dental lab makes the mouth guard through heat-forming, pressure-layering, or 3D printing.

- Fitting and Adjustment: When the guard is ready, the dentist will do a careful fitting and make any needed adjustments in the chair to ensure it is comfortable, stays in place, and the bite is right.

- Patient Instructions: The athlete gets full instructions on how to put in, take out, clean, and care for the mouth guard.

Who Should Use Our Custom Athletic Mouthguard?

Anyone who plays sports can get great benefits from a custom sports guard. These groups especially need strong mouth protection:

- Youth players (soccer, football, basketball)

- Adult athletes (all contact/collision or high-fall risk sports)

- Patients with braces

- Professional teams and clubs

- Dental clinics and hospitals that offer special sports dentistry services

How to Order

- Send us a patient’s mold or digital scan.

- Choose features, colors, and style.

- We deliver the custom made mouthguard for sports to your clinic or lab, ready to fit.