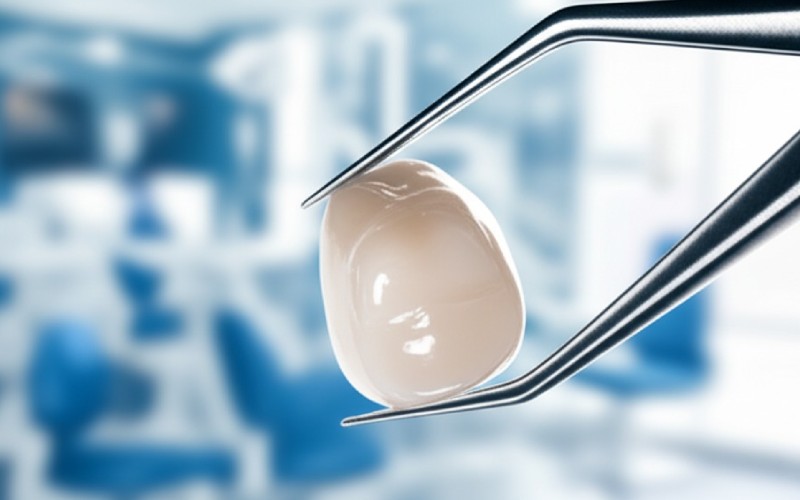

Dental Implant Prosthetics

Your Skilled Partner for Modern Dental Implant Prosthetics

As Istar Dental Lab, a top 5 dental lab in China, we offer skilled lab services for dental implant prosthetics to dentists, dental clinics, and dental hospitals of any size. We help you give your patients their smiles back. Our goal is to give you clear and helpful information. Our service includes everything from a single tooth implant prosthesis to a full arch restoration. We work with you to make sure every patient gets the best outcome. This makes patients happier and improves their lives.

Different Uses and Types

Dental implant prosthetics offer many different solutions for all kinds of patient situations, from replacing one missing tooth to fixing a whole row of teeth. Our lab supports different types of work, each made for a patient’s specific needs and treatment goals.

Single-Unit Crowns

Single-unit implant-supported crowns are the most common use, replacing one missing tooth. These new teeth are usually made from zirconia, lithium disilicate (Emax), or PFM, picked for their great looks, strength, and safety in the body. The design is focused on getting the best look where the tooth comes out of the gum, a natural shape, and a perfect bite to fit in perfectly with the nearby teeth.

Fixed Partial Dentures (Bridges)

Implant-supported fixed partial dentures replace several missing teeth in a row, held in place by two or more implants. These can be 3-unit bridges or cover bigger gaps. Materials like zirconia and titanium are often used for the base, and are frequently covered with ceramics for a better look. We think carefully about the connector design and how chewing pressure is spread out to make sure it lasts a long time and doesn’t break.

Full-Arch Restorations

Full-arch implant prostheses are made to replace a whole row of missing teeth, giving a permanent solution that doesn’t come out. These are difficult cases that need careful planning and work.

- Hybrid Prostheses: Usually have a metal (titanium or cobalt-chromium) or PEEK base with an acrylic or composite layer on top, often held by 4 to 6 implants. These are known for being a good value and for their ability to soften bite pressure.

- Full-Arch Zirconia Bridges: Monolithic or layered zirconia bridges have great looks and strength, often held by 4 to 8 implants. They are very strong but need careful bite adjustment because of zirconia’s stiffness. Our designs focus on using the right number of implants, placing them correctly, and keeping overhangs short to make sure they last.

Immediate Loading Protocols

Immediate loading means putting a temporary prosthesis on implants soon after they are put in, often within 24 to 72 hours. This method makes the treatment much shorter and makes patients happier. But, it’s very important to choose the right patients for this to work well:

- Primary Implant Stability: This is the most important thing, measured by insertion torque (>35 Ncm) and/or Implant Stability Quotient (ISQ) values (>65). We use measurements taken during surgery to make sure it’s stable enough.

- Bone Quality and Quantity: Good, strong bone is very important. Modern scanning tools like CBCT-based bone density mapping are part of our planning.

- Systemic Health: While not always a deal-breaker, health problems that are under control (like diabetes or osteoporosis) and not smoking are very important. We work closely with dentists to check and handle patient risks.

- Parafunctional Habits: Bruxism and heavy bite forces are big risks. Patients with heavy teeth grinding might need special bite plans, night guards, or even to wait longer before getting their final teeth. Digital occlusal analysis and nocturnal EMG monitoring are helpful for measuring the risk.

- Digital Workflow and Guided Surgery: Fully digital methods, including guided surgery, make the results more certain by finding the best spot for the implant based on the available bone and the space for the new teeth. This is especially helpful in tough cases like when the upper jaw bone has shrunk.

Many studies show that the 5-year success rates for immediate loading are about the same as the standard way (96–98%), as long as the right patients are chosen. While there might be a tiny bit more bone loss at the edge, the good things for the patient are very big. We support custom plans for immediate loading, using computer models of bite forces and patient-specific information to get the best results.

Esthetic Zone Cases

Fixing teeth in the smile zone (the front teeth) needs very careful and skillful work. Our method focuses on:

- Material Selection: Choosing materials that look great, like high-translucency zirconia or lithium disilicate (Emax).

- Soft Tissue Management: Designing the new teeth to support and shape the gums around the implant, creating natural-looking gums.

- Custom Abutments: Making custom abutments (from zirconia or titanium) to improve how the tooth comes out of the gum and give a smooth, natural look from the implant to the crown.

- Color Matching: Using modern digital color-matching tools and expert technicians to get a perfect match with the patient’s natural teeth.

The Building Blocks of a Perfect Smile

A great new tooth depends on great parts. We use only the best pieces for our dental implant prosthetics.

| Component | Simple Description |

| Dental Implant / Implant Fixture | The post that goes into the bone. |

| Abutment | The piece that connects the implant to the crown. |

| Prosthetic Screw | The screw that holds the crown onto the abutment. |

| Impression Coping | Used to take an exact model of the implant’s position. |

| Implant Analog | A copy of the implant used in the lab model. |

We understand the details of the implant-abutment connection. We work with every type, including:

- External hex connection

- Internal hex connection

- Conical connection

Our designs use smart features like platform switching to help keep the bone healthy. We carefully shape the emergence profile so the new tooth looks like it is coming right out of the gums. This helps you build a new tooth that is not just strong but also beautiful.

Advanced Manufacturing and Digital Workflows

The way dental prosthetics are made has been completely changed by new technologies and connected digital steps. At Istar Dental Lab, we smoothly mix cutting and 3D printing methods within a complete digital system to make very exact, custom, and fast implant prosthetics.

Subtractive Manufacturing (CAD/CAM Milling)

CAD/CAM milling is still a key part of how we make things. This cutting method involves carefully cutting a new tooth from a ready-made block of material (like zirconia, titanium, PEEK, or lithium disilicate) using computer-controlled machines.

- Accuracy: High-end 5-axis milling machines get an excellent fit at the edges, usually between 10–40 μm, making sure it fits perfectly on the implant abutments and prepared teeth.

- Surface Quality: Milled parts usually have very smooth surfaces (Ra < 1 μm), so they need very little finishing work.

- Material Range: A wide choice of materials is available in blocks, offering flexibility for different dental needs.

- Efficiency: Even though it’s one by one, milling is very fast for single teeth or small bridges, usually taking 1–2 hours for each tooth.

Additive Manufacturing (3D Printing)

Additive manufacturing (AM), or 3D printing, is quickly changing what we can do, especially for difficult shapes and for making many at once. Methods like Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are used for metal bases, while stereolithography (SLA) and Digital Light Processing (DLP) are used for resins and some ceramics.

- Accuracy: Metal AM gets a fit at the edges that is as good as or a little less precise than milling, between 20–60 μm, but it’s always getting better. The final accuracy needs a lot of finishing work.

- Material Versatility: AM lets us use advanced alloys (like titanium alloys, cobalt-chromium) and new materials that are hard to cut. There is a growing interest in printable hybrid composites and functionally graded materials.

- Production Efficiency: AM allows for making many replacement teeth at once in a single run, cutting down the work for each one. A single build plate can fit 20–40 implant bars or crowns, with total build times of 4–8 hours. This saves a lot of money for bigger orders or complex, multi-unit bases.

- Geometric Freedom: AM is great for making complex inside structures, like lattice designs, which can lower the weight but keep the strength.

- Surface Quality and Post-Processing: AM parts usually need more finishing work (like sandblasting, electropolishing, or CNC finishing) to get the smooth surface and edge fit we need. The surface roughness (Ra) after AM is typically 5–15 μm.

In-Process Quality Control and Regulatory Compliance

Our making processes include careful checks during the process. This includes advanced optical tomography and melt pool monitoring in AM, which find problems in each layer as it’s made. This makes sure every one is the same and means we don’t have to break them to test them. We closely follow international rules for checking our process, tracking parts, and certifying materials, making sure all our products are top quality and safe.

Advanced Materials for Lasting Results

The right material is key to a good result. We offer a full range of materials that are safe for the body.

- Metals: We use Titanium and Titanium alloy. These are very strong and safe. They are often used for PFM (porcelain fused to metal) and metal-ceramic restorations.

- Ceramics: We offer the best in all-ceramic restorations. This includes beautiful and strong materials like Zirconia, Ceramic, and Lithium disilicate (E.max). A full-contour zirconia crown is a very popular choice.

- Polymers: We also use modern materials like Acrylic resin and PEEK (polyetheretherketone) for certain types of prostheses.

Clinical Excellence and Partnership

We are your partners in handling tough cases. We understand how bite forces work and the chewing forces that dental implant prosthetics must handle. We help you plan for issues like:

- Bruxism and parafunction.

- Managing the crown-to-root ratio.

- Deciding when connecting implants to teeth is a good idea.

- Designing a safe cantilever.

We also help you prevent problems like peri-implantitis, screw loosening, prosthesis fracture, or veneer chipping. Our goal is to prevent implant failure and make sure it lasts a long time. Our designs prevent gaps between teeth and food getting stuck. We work hard to prevent problems with how it looks, like gums pulling back.

Our Partners in Innovation

We make sure our dental implant prosthetics are compatible with all major brands. This gives you the flexibility to choose what is best for your clinic.

Contact us today to start your first case. Let’s work together to build beautiful, lasting smiles.