Veneer

As Istar Dental Lab, a top company worldwide and one of China’s top five dental laboratories, we are leading the way in new ideas and great work in the dental veneer field. Istar Dental Lab uses the newest material science, the best making technologies, and very strict quality check rules to provide top-quality veneers. Our dedication to always improving, working efficiently, and having strong communication with clients makes us a key partner in meeting the changing needs of cosmetic dentistry.

Istar: A Natural and Durable Veneers Dental Lab

Dental veneers are thin, specially made covers designed to go over the front of teeth, making them look better by fixing problems like staining, chips, gaps, or crookedness. They are a key part of modern cosmetic dentistry, offering patients a long-lasting and very good-looking solution for making their smiles better.

The dental laboratory plays a very important part in the good results of veneer treatments. Our services are much more than just making them; we are a key part of the design, material choice, careful making, and quality check steps that turn a dentist’s idea into a real, perfectly fitting piece.

Why Choose Our Veneers Dental Lab?

Choosing the right lab is a big choice. We make it an easy one. Our team is focused on three key things: amazing looks, a perfect fit, and great support for you.

The Art of a Natural Look

Choosing the right material is very important for the success and how long dental veneers last. It’s about finding a balance between how strong they are, how they look, and when they should be used. At Istar Dental Lab, we work with many different new materials, each with its own benefits.

Our Natural Veneers at One Glance: Options for Every Patient

We offer many types of veneers. This helps you find the right choice for every patient. Each dental veneer we make is a custom piece of art. We offer many kinds of affordable veneers.

| Veneer Type | Main Material | Best For |

|---|---|---|

| E.max Veneers | Advanced Lithium Disilicate Ceramics | A great mix of strength and good looks, veneers that require less tooth preparation, partial crowns, medium staining, and cases needing higher strength. |

| Zirconia Veneers | Modern zirconia formulations (e.g., 4Y/5Y-PSZ) | The highest bending strength, areas with a lot of bite force, bad staining, or when a very thin veneer is needed. |

| Composite Veneers | Reinforced resin composites | Better bending strength and easier to repair, simple in-office solutions, especially in markets where cost is a big factor. |

Primary Veneer Materials and Their Properties

Advanced Lithium Disilicate Ceramics (Emax): Being a big step forward, these ceramics offer a great mix of strength and good looks. They show much higher bending strength (360–500 MPa) and resistance to breaking (2.5–3.0 MPa·m^0.5), which allows them to be used for veneers that require less tooth preparation and for partial crowns. Their see-through quality (TP: 28–32) is similar to real teeth, and they come in different levels of clearness for different patient situations. These materials are good for medium staining and cases needing higher strength, but need to be thought about carefully for people who grind their teeth a lot.

Zirconia: New types of zirconia, especially the ones with more yttria (e.g., 4Y/5Y-PSZ), have the highest bending strength (600–1200 MPa) and resistance to breaking (5–10 MPa·m^0.5). While older zirconia wasn’t very see-through, new types are much better, though still usually not as good-looking as glass ceramics for front teeth that need to look perfect. Zirconia is very safe for the body, and plaque doesn’t build up on it much. It is recommended for areas with a lot of bite force, bad staining, or when a very thin veneer is needed. Coming off can be a main reason they fail because it doesn’t bond well chemically, requiring special surface preparations and bonding steps.

Biocompatibility and Clinical Performance

All three main materials are seen as very safe for the body, with lots of studies that support their safety and how they work with the mouth’s tissues. Long-term studies show strong long-term success rates: Emax veneers show 10-year success rates of 92–98%, showing they are less likely to break and have better-fitting edges. Zirconia veneers, especially the single-layer types, show that early studies look good with 90–95% success rates.

Preparation Designs and Bonding Protocols

The best tooth preparation is key for making veneers last a long time. Emax veneers work best when prepared on the tooth’s enamel (0.3–0.7 mm removed), which helps get the strongest bond. Zirconia veneers might need more of the tooth to be prepared or special surface treatments (like air abrasion or special primers) to make the bond stronger. Using immediate dentin sealing and universal glues has shown better results for all-ceramic veneers.

Manufacturing Processes and Their Impact

Advanced lithium disilicate ceramics are made using heat-press methods or CAD/CAM milling, and digital methods give more consistent results. Zirconia veneers are only made by CAD/CAM milling, and the heating process and amount of yttria greatly affect how they turn out.

Emerging Materials

The world of materials is always changing. Reinforced resin composites offer better bending strength (150–220 MPa) and are easier to repair, becoming more popular for simple, in-office solutions, especially in markets where cost is a big factor. The market for all-ceramic veneers is currently led by Advanced Lithium Disilicate Ceramics, but the fast development of very see-through zirconias and hybrid ceramics is creating more choices. Digital methods are speeding up the use of these new materials, making it possible to have thinner, better-looking veneers.

Technology for a Perfect Fit

At Istar Dental Lab, our focus on being exact and fast is supported by our use of new making technologies, especially CAD/CAM and 3D printing, which are changing how veneers are made.

CAD/CAM Adoption and Impact

Digital CAD/CAM technology is a key part of how modern dental labs work. While the worldwide use of CAD/CAM for general tooth replacements is high (65–75%), the use for veneers specifically is growing fast, at about 40–55% globally. Leading labs like ours are using it for over 80% of our veneers.

Reasons for Use:

- Better Accuracy: CAD/CAM systems provide a fit at the edges that is accurate to less than 50 microns, greatly cutting down on differences from doing it by hand.

- Faster Work: Making time can be cut by up to 50%, leading to quicker delivery times.

- Less Waste: Digital methods cut down on wasted material by about 20-30%.

- Consistent Looks: A better ability to repeat results and keep them the same is a big benefit for expensive cosmetic work.

3D Printing Applications in Veneer Fabrication

3D printing is another technology that is changing everything. It is used in many steps of our veneer process, improving speed and custom fitting.

Where It’s Used in the Process:

- Diagnostic Wax-ups: Quick making of special models for each patient for planning the treatment and talking with the patient.

- Provisional Veneers: Making very exact temporary veneers for the patient to try in and for checking how they work.

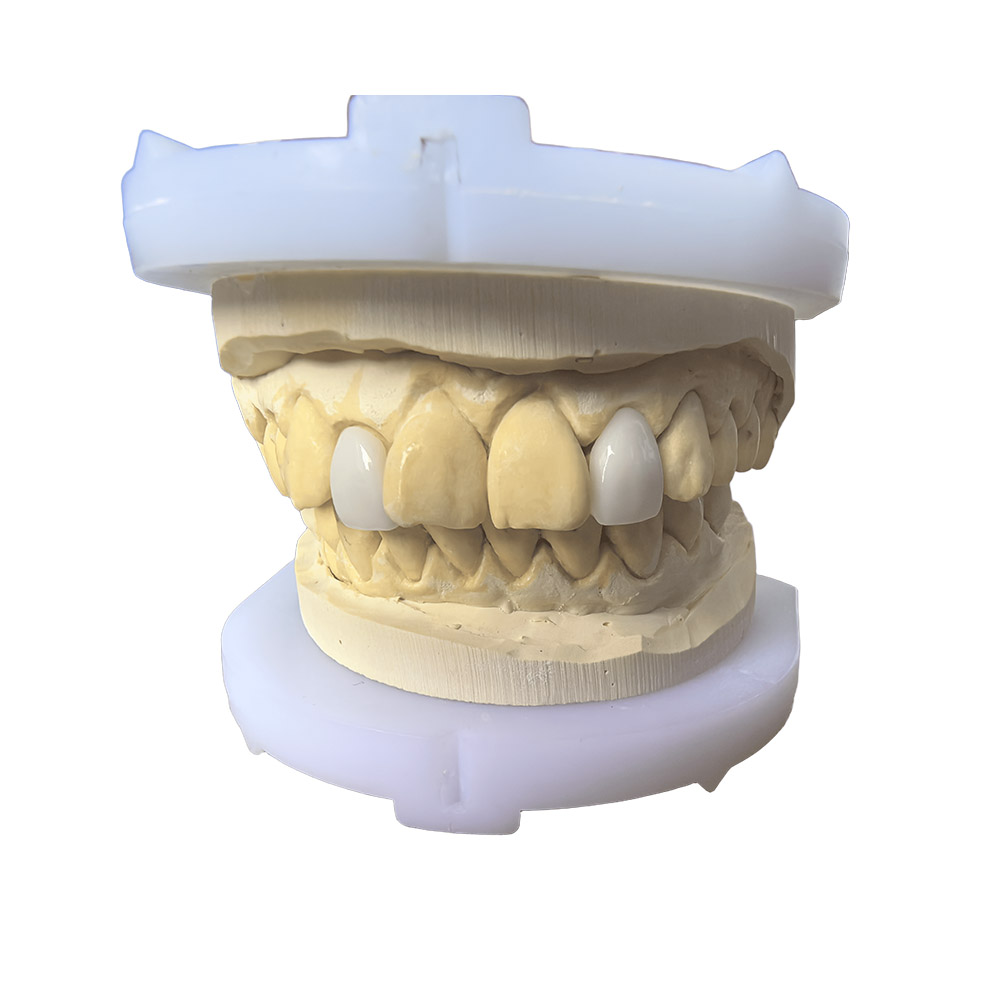

- Working Models: Making exact models to work on for pressable or layered ceramic veneers.

- Custom Trays and Guides: Making special impression trays and guides for preparing teeth.

Technology and Materials: Stereolithography (SLA) and Digital Light Processing (DLP) are the main 3D printing technologies because they are very detailed and have a smooth surface. We use body-safe light-cured resins for diagnostic and temporary uses.

At Istar Dental Lab, quality checks (QA) are not just a step; they are a core part of how we work. This makes sure every veneer we make is of the highest quality in terms of accuracy, looks, and success for the patient. Our rules are designed to help our work fit perfectly with what dentists do, having fewer re-dos and making patients as happy as possible.

Digital Workflow Integration for Precision

The main support for our quality checks is our complete digital process:

- CAD/CAM Systems: Our new digital design and milling systems make sure the accuracy and sameness are the best possible, cutting down on the human error found in old methods.

- Intraoral Scanners and Digital Impression Verification: We use top in-the-mouth scanning systems to get very exact digital models. These digital models are carefully checked for how the edges fit and where they touch before they are made, greatly cutting down on mistakes that come from the molds.

- Spectrophotometric Shade Analysis: We use digital color-measuring tools for unbiased and repeatable color choices. This technology gives an exact digital color map, reducing errors based on personal opinion and making sure the color match is right.

- Digital Microscopy and Surface Quality Control: We use powerful digital microscopes to check the veneer edges, surface feel, and final look. We try to get the edge gap to be smaller than 50 μm and record how smooth the surface is, saving digital pictures for complete quality records.

- Contact Point Integrity Assessment: We use new materials that show pressure and digital bite-checking systems to check and record how accurately the teeth touch, often with the help of 3D printed models for trying them in.

A True Partner for Your Practice

Good communication is very important for working well with the dentist’s treatment. We use organized digital websites for sending cases that need detailed order forms, clear digital photos (including polarized and cross-polarized images), and exact color maps. Live chat and video calls are being used more and more for planning cases together, making sure everything is clear and reducing mistakes in communication.

We are a lab that does everything. We also do crown and bridge work and work with dental implants. We are your one-stop shop for replacement teeth.

How We Create the Perfect Dental Veneer

Our process is simple and clear. We make it easy for you to work with our veneers dental lab. Here are the steps we follow for your natural veneers case.

- Send Us Your Case: You can send us a digital file from your scanner or a physical dental impression.

- Digital Smile Design (DSD): We create a plan. We can make mock-up veneers so the patient can see the new look. This helps with case acceptance.

- Veneer Creation: Our dental ceramist begins the work. Advanced lithium disilicate ceramics are made using heat-press methods or CAD/CAM milling, and digital methods give more consistent results. Zirconia veneers are only made by CAD/CAM milling, and the heating process and amount of yttria greatly affect how they turn out.

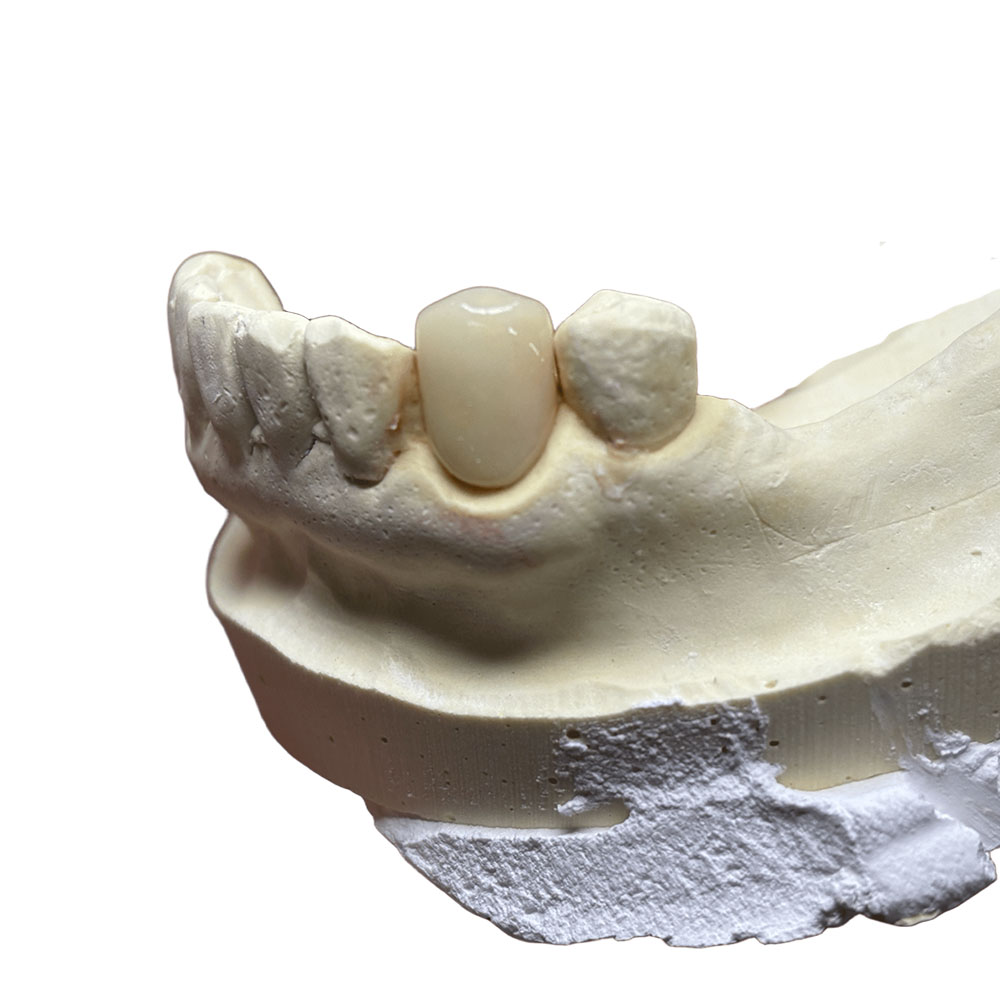

- Color and Customization: We match the shade and add details. The veneer may go into a bisque stage try-in for a final check.

- Finishing Touches: We glaze and polish the veneer. Then we use a dental bonding agent and light-cured resin cement for final prep.

- Quality Check and Shipping: We do one last check. We watch key numbers to make sure our veneers are good and keep getting better:

- Marginal Gap: Aiming for less than 50 μm.

- Contact Tightness: Measured to ensure proper fit between teeth.

- Shade Match Accuracy: Targeting a ΔE (color difference) of less than 2.0.

- Surface Roughness: Keeping a low Ra value (e.g., < 0.2 μm) for the best looks and resistance to plaque. These numbers are written down in our quality records and used to always get better and for feedback from dentists. Then we send the finished case to you, ready for the patient.

A Lab Built by Experts

Our team is led by a master ceramist. Our staff has the best dental technician training. We strictly follow international rules for quality, including ISO 13485 (Medical Devices—Quality Management Systems) and ISO 9001 (Quality Management Systems). These certifications require detailed written steps for every stage of making veneers, from tracking materials to checking equipment and having a system to fix anything that goes wrong. We also follow national government rules, like those in the US (FDA 21 CFR Part 820) and the UK (DAMAS), making sure we can sell worldwide and that people trust us. We believe in continuing education for dentists and for our own team. We work with every kind of expert, from a general dentist to a prosthodontist. Our lab helps your dental practice marketing by giving you great results to show off. We are a top veneer lab.

Start Your Journey to a Better Smile Today

Are you ready to give your patients the best natural veneers?

We make it easy to start. Let us show you why so many dentists trust our veneer lab. We offer great work and affordable veneers.

Contact us today to get your starter kit.