Zirconia

As Istar Dental Lab, a leading global dental laboratory based in China, we are dedicated to advancing the field of restorative dentistry through cutting-edge zirconia solutions. Our aim is to empower our valued partners—dentists, dental clinics, hospitals, and fellow dental laboratories worldwide—with the knowledge to leverage the full potential of zirconia for superior patient outcomes.

Your Skilled Partner: An All-in-One Zirconia Dental Lab

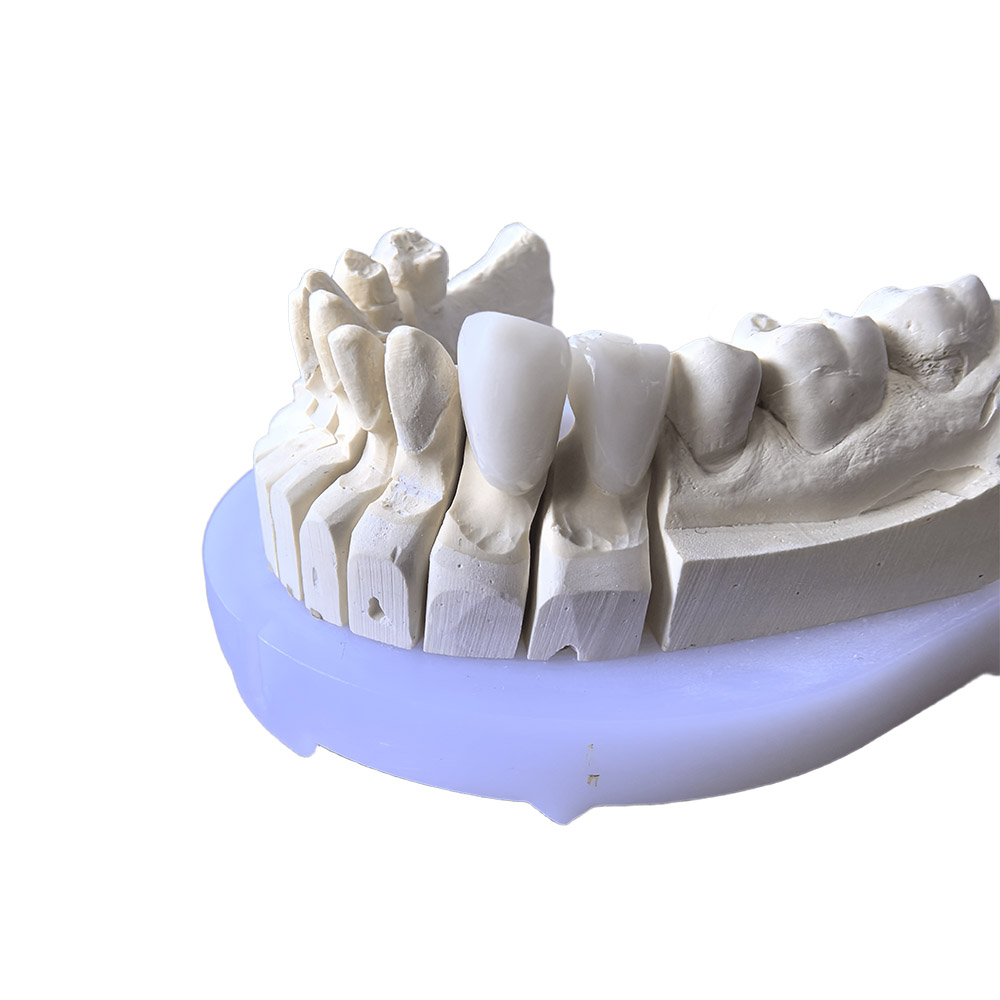

At Istar Dental Lab, our main work is designing, making, and finishing top-quality dental products using a material called zirconia. Our role in modern dentistry is very important: we take digital scans and a dentist’s instructions and turn them into exact, long-lasting, and beautiful dental pieces that bring back the use and look of natural teeth for patients everywhere. Zirconia has become the most popular material for many different dental uses, showing a big change in how we restore teeth.

Why Choose Our Zirconia Lab?

Choosing the right lab is an important decision. You need a partner you can trust. We work hard to be the best zirconia dental lab for your practice. We are professional and careful in our work. Here is why top dentists choose us:

Top Quality: We only use the best materials that are safe for the body. Every zirconia piece we make is checked very carefully in our dental labs.

Great Looks: Our work looks natural and beautiful. We are skilled at making things look good and matching colors perfectly.

Newest Technology: We use a complete digital process. This includes CAD/CAM dentistry for a perfect fit.

Great Support: Our team of trained dental experts is ready to help you with any project. We try to make complex things simple.

Our Zirconia Restoration Products

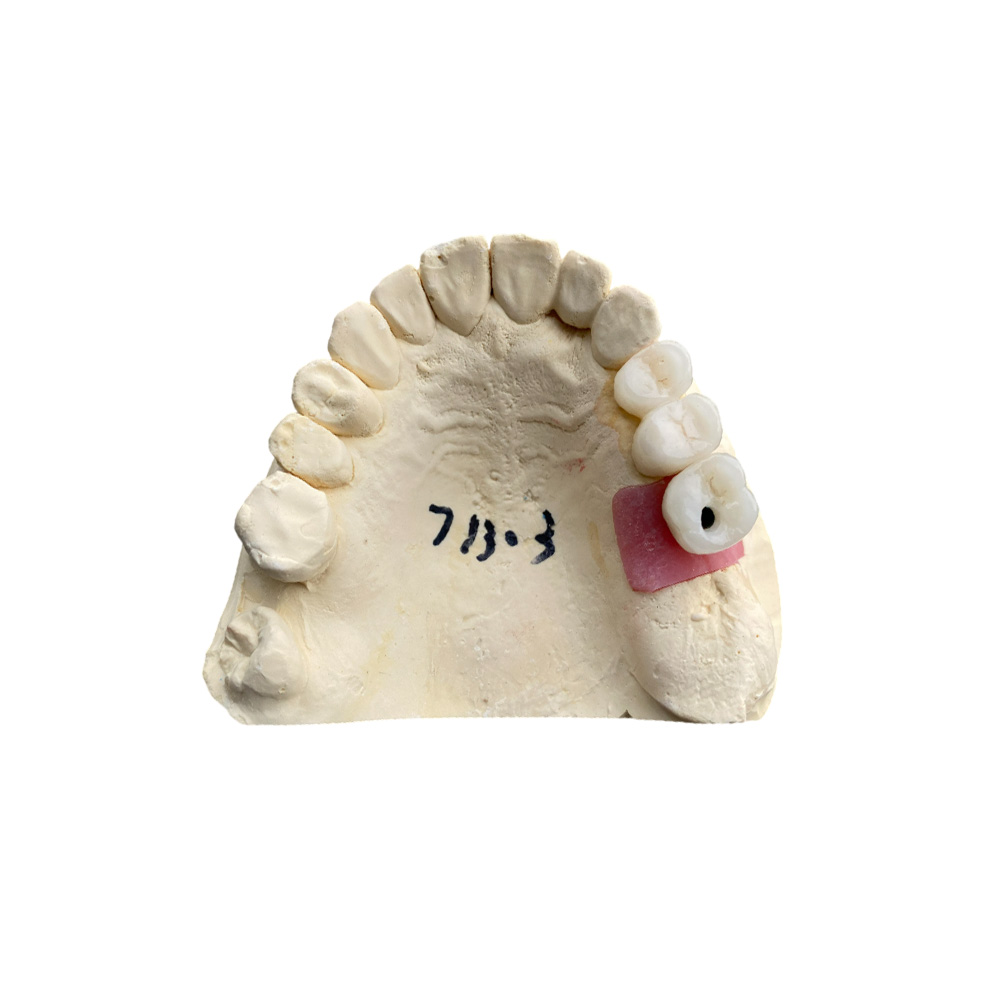

Zirconia’s flexibility and great features make it good for many different dental fixes. At Istar Dental Lab, we use these features to make top-quality, custom products for different patient needs. Our full list of zirconia products includes:

| Product | Best For | Material Details |

|---|---|---|

| Zirconia Crowns | Fixing a single tooth, the most common use for zirconia, liked for being strong, looking good, and being safe for the body. | Monolithic Zirconia: (e.g., 3Y-TZP, 4Y/5Y-PSZ) has high bending strength (900–1200 MPa for 3Y-TZP). |

| Zirconia Bridges | Pieces that replace one or more missing teeth, especially for back teeth that take a lot of bite pressure. | Layered Zirconia: It has a zirconia base with a layer of feldspathic porcelain on top. |

| Zirconia Veneers | Thin, custom-made covers that are attached to the front of teeth to make front teeth look better. | Multi-layered/Translucent Zirconia: A big step forward, mixing good looks with strength (bending strength 650–900 MPa). |

| Zirconia Inlays and Onlays | Fixes that cover part of a tooth to fix a damaged tooth, a less invasive option than a full crown. | Cut from one block to fit perfectly at the edges. |

| Zirconia Dental Implants | Includes implant abutments (the connector between the implant and the crown) and solutions that support a full row of teeth on implants. | Zirconia’s strength and safety for the body are big benefits. |

Material Properties and Clinical Performance

How well zirconia products work depends a lot on the exact type of material used:

Monolithic Zirconia: (e.g., 3Y-TZP, 4Y/5Y-PSZ) has high bending strength (900–1200 MPa for 3Y-TZP) and is resistant to cracks (5–10 MPa·m1/2). This makes it great for long bridges and areas that get a lot of pressure.

Layered Zirconia: Has a zirconia base with a layer of feldspathic porcelain on top. While it looks better, it can break more easily because the top layer might chip or peel off, especially in back bridges (up to 15% at 5 years).

Multi-layered/Translucent Zirconia: Is a big step forward, mixing good looks with strength (bending strength 650–900 MPa). These materials mix layers with different amounts of yttria and color to look like a real tooth, allowing them to be used for both front teeth and short bridges in the back. They chip less often than the older layered types.

Our Modern Digital Process

At Istar Dental Lab, our dedication to being exact and fast is shown in our complete digital process, which uses the latest CAD/CAM technology and modern making methods. This new digital way of working has completely changed how we make zirconia dental products, making sure they are incredibly accurate, fast, and always the same quality.

The Complete Digital Process

- Intraoral or Lab Scanning: The process starts by taking very precise digital scans using advanced intraoral scanners or by scanning physical models with our lab scanners. These devices are known for their high accuracy, with mean deviations often below 20μm for full-arch scans.

- Digital Design (CAD): The digital scan is then put into special CAD computer programs. These programs have new tools like AI to find edges, automatic tooth shape creation, and online sharing tools, letting our skilled team design dental pieces that are very exact and look great.

- CAM Preparation and Nesting: Once the design is ready, it is sent to the CAM program. This step gets the design ready to be made. This includes fitting the design onto a zirconia block to use the material wisely and create less waste.

- Milling: The prepared design is then sent to advanced 5-axis milling machines. These machines can do high-speed dry and wet milling, making single crowns in as little as 12 to 30 minutes, depending on the machine and material. This type of milling is still the best method for zirconia pieces because it is very precise and leaves a smooth surface.

- Sintering: After milling, the newly milled zirconia piece goes through a high-temperature heating process in special ovens. This very important step makes the material stronger and more solid, giving it its final strength and see-through look. Modern sintering ovens can complete this process for single units in as little as 90 minutes.

- Finishing and Characterization: After heating, the dental pieces are carefully finished, colored, and glazed to look natural and have a smooth finish. This step often mixes hand-crafting skills with digital tools to make sure the color and feel of the surface are perfect.

- Final Quality Control: Every piece goes through strict quality checks, including checking its size, fit, look, and strength, before it is approved.

- Delivery: The finished, top-quality zirconia piece is then sent to the dentist to be placed in the patient’s mouth.

New Ways of Making Things

While milling is the most common method, Istar Dental Lab is always looking for and using new ways of making things to do more with zirconia than ever before.

A lot of progress has been made in the 3D printing (additive manufacturing, or AM) of zirconia dental pieces. Technologies like Lithography-based Ceramic Manufacturing (LCM), which is a type of 3D printing like Stereolithography (SLA) or Digital Light Processing (DLP), are now being used for zirconia by using special liquid ceramic mixtures. This lets us make strong, solid zirconia parts with very detailed shapes. After printing, they are cleaned and heated to become hard.

Benefits of 3D Printing for Zirconia:

- Saves Material: 3D printing methods use much less material (up to 80% less than milling), which saves money and is better for the environment.

- Complex Shapes: 3D printing can create very complex shapes made just for one patient (like hollow parts or tiny channels) that are hard to make with milling. This makes it easier to make custom items for many people.

- Saves Money: Even though the 3D printing machines cost a lot at first, the cost for each item goes down as we make more and waste less material. This is especially true when making small numbers of very custom items.

Our Focus on Quality

At Istar Dental Lab, checking for quality is not just a step; it is the foundation of everything we do. We use very strict quality control rules at every stage of making zirconia products to make sure every product meets the top world standards for looks, function, and safety. We are fully committed to being exact and trustworthy.

Material Standards and Following the Rules Our quality system is based on following strict international rules. ISO 6872:2019 is the main international rule for dental ceramic materials, including zirconia. It sets rules for bending strength (e.g., ≥500 MPa for Type II, Class 5 zirconia), how it reacts to chemicals, and if it’s safe for the body. Following ISO 13356 (for Y-TZP ceramics) is also common. These rules are the base for how we choose and work with our materials.

Key Control Points in Sintering The heating process is a key step that decides the final quality of the zirconia. We carefully control every part of it:

- Temperature Profiles: The top temperature (usually 1350–1550°C), holding time (1–2 hours), and heating/cooling speeds (5–20°C/min) are carefully controlled. If these are not right, the material might not get hard enough, or it could change in ways that affect its strength and look.

- Density Measurement: We use the Archimedes’ method, which is standard in the industry, to measure the density of the heated zirconia, aiming for a density that is more than 99% of the perfect level. We also use automated helium pycnometry for more exact measurements in our quality labs.

- Phase Analysis: We regularly use X-ray diffraction (XRD) to check the material’s structure after heating. Too much of the ‘monoclinic’ type (>2–3%) is a warning sign that the material could weaken over time. Raman spectroscopy is a new, fast way to check this without damaging the part.

Checking Mechanical and Visual Properties

- Bending Strength Testing: Three-point and four-point bending tests, as per ISO 6872, are standard ways we test bending strength. Our high-translucency Y-TZP materials consistently achieve values of 900–1200 MPa. We use automated testing machines as a key part of our making and research work.

- Color and Visual Quality Control: We use a special system called spectrophotometric colorimetry (CIE Lab* system) to make sure the color and clearness are exactly right. We use color-checking systems during the process to find any mistakes, which can be caused by the heating process or the material itself.

Finding Flaws and Post-Sintering Work

- Finding Internal Flaws: We use advanced methods like micro-CT scanning and ultrasonic testing to find tiny holes, cracks, or other flaws inside the material without damaging it. These methods are much better at finding problems than just looking with the eye, especially for expensive pieces that replace multiple teeth.

- Post-Sintering Work: Glazing and polishing after heating are very important to get the best smooth surface, resistance to wear, and good looks. We make sure the glazing is done right to prevent surface problems or color changes. Some of our processes include advanced polishing methods for a better surface that bacteria are less likely to stick to.

Partner With Us Today

Are you looking for a new zirconia lab? Are you thinking about outsourcing dental lab work? We have clear prices and a great warranty for our dental products. We also provide training materials for dental technicians.

Let our zirconia dental lab be the partner you can count on. We want to help you make your patients smile. The benefits of working with us are clear.

Contact us today to send your first case.