Custom Dental Guard

As Istar Dental Lab, a top dental lab that works with people all over the world, we are focused on helping dentists and labs everywhere with the newest and best solutions. Our skill in making custom dental guards shows how much we care about getting things exactly right, keeping patients comfortable, and using the latest technology.

01.

Saving Time and Money

The digital making process is much faster and more efficient. The whole process, from scan to delivery, can be done in just 2-4 days, which is much faster than the 12-15 days needed for older methods. While buying 3D printing equipment costs a lot at first, the cost to make each guard is much lower than with old lab methods, especially when we print many at once.

02.

Precision Fit with Advanced Technology

Utilizing state-of-the-art equipment such as 3D dental scanners and CAD/CAM systems, we create night guards that offer a perfect fit for your patients. This ensures maximum comfort and compliance, leading to better outcomes and patient retention for your practice. Our guards are custom-made to match your patients' grinding patterns and fit their upper or lower teeth precisely.

03.

Make Patients Happier

Our goal is simple. We help you give your patients the best care. We do this with a great custom mouth guard that is made just for them. Let us handle the details, so you can focus on your patients' smiles. We make the whole process smooth and easy for you.

Our Full Range of Custom Dental Protection

We make protective dental guards for many different reasons. Each custom dental guard is made with care by a skilled Dental Technician. Custom dental guards can be used in many ways, helping to treat problems and protect teeth for all kinds of patients. Their perfect fit and the materials they’re made from are the most important things for making them work well for these different uses:

Night guards, sometimes called occlusal splints, are mainly made to lessen the harmful effects of bruxism—which is when people grind or clench their teeth without meaning to, either while asleep or awake. These guards protect teeth from wearing down too much, make the jaw muscles less tired, and ease related problems like headaches and temporomandibular joint (TMJ) pain. They are usually made from strong materials like hard acrylic or special two-layer plastics, chosen because they can handle strong bite pressure and create a steady surface for the teeth to rest on.

Sports mouthguards are designed to soak up and spread out the force of a hit, greatly lowering the chance of injuries to the mouth and face during sports. These guards are very important in contact sports and are often required by sports groups. Mostly made from a flexible material called ethylene-vinyl acetate (EVA) or something similar, they absorb shock much better and are more comfortable than the store-bought kind. Studies show again and again that they work well to prevent broken teeth, cuts to the mouth, and even concussions.

Orthodontic retainers are custom-made devices that are needed to keep teeth in place after orthodontic treatment. They stop teeth from moving back to where they were, making sure the results from the braces last a long time. Different types include the classic wire-and-plastic retainers and clear plastic retainers. The choice depends on what the patient needs and prefers.

Custom trays for professional teeth whitening that help spread the whitening gel evenly and protect the gums.

Oral appliances that aid in managing sleep apnea symptoms by adjusting the jaw position.

10+ years of manufacturing experience

10000 square meters of modern dental lab

300 technicians with various advanced machines

Safe Materials We Use

We use a wide variety of safe plastics for custom dental guards. We choose each one for its special strength and how it works in the body:

- Ethylene Vinyl Acetate (EVA): The main material for soft custom guards. It’s flexible and comfortable, which is great for people who grind their teeth lightly and for sports mouthguards.

- Polymethyl Methacrylate (PMMA): The go-to material for hard dental guards. It’s very strong and durable, which is best for people who grind their teeth a lot and need major bite correction.

- Polycarbonate and Copolyester Blends: Used to be extra strong against hits. They are tougher and less likely to crack, making them good for sports.

- Multi-layered and Hybrid Designs: Newer designs mix a soft inside layer for comfort with a hard outside layer to make it last longer, giving patients the best of both.

All materials we use meet strict official standards, like ISO 10993 for safety in the body and ISO 20795-2 for dental plastics, to make sure they are safe and work well.

How We Make Guards

The way custom dental guards are made has changed a lot. We’ve moved from old-fashioned methods that took a lot of work to very exact digital processes. This change is supported by new and better materials, which make sure the guards work great, are safe for the body, and are comfortable for the patient.

Today’s making process usually starts with a digital scan inside the mouth, using special tools to get a very detailed 3D picture of the patient’s teeth. These digital files are then put into special dental design (CAD) software to create a custom design. This digital plan lets us make very careful changes, like perfecting the bite and controlling the thickness, before the guard is made.

Stereolithography (SLA) and Digital Light Processing (DLP) are the main types of 3D printing we use to make custom dental guards. These printers are incredibly detailed, which is needed for the perfect fit of a device that goes in the mouth. They also work with special resins that are safe to use in the body. Another type of 3D printing, FDM, is not usually used to make the final guard, but it might be used to make molds or early models.

After being 3D printed, the dental guards need a few more steps to be finished. This usually means washing them with a special alcohol (IPA) to clean off extra material, then using a UV light to fully harden them so they are strong and safe. The last steps are done by hand, like removing supports and polishing. This makes the final guard smooth, comfortable, and clean.

The Simple Process for Your Clinic

Getting a custom dental mouth guard for your patients is easy.

- Send an Impression: Use your intraoral scanner to send a digital file. Or, use our simple at-home dental fitting kit.

- We Create the Guard: Our dental lab team gets to work. They create the perfect custom bite guard.

- Fast Delivery: We ship the finished custom dental guard back to your clinic, ready for the patient.

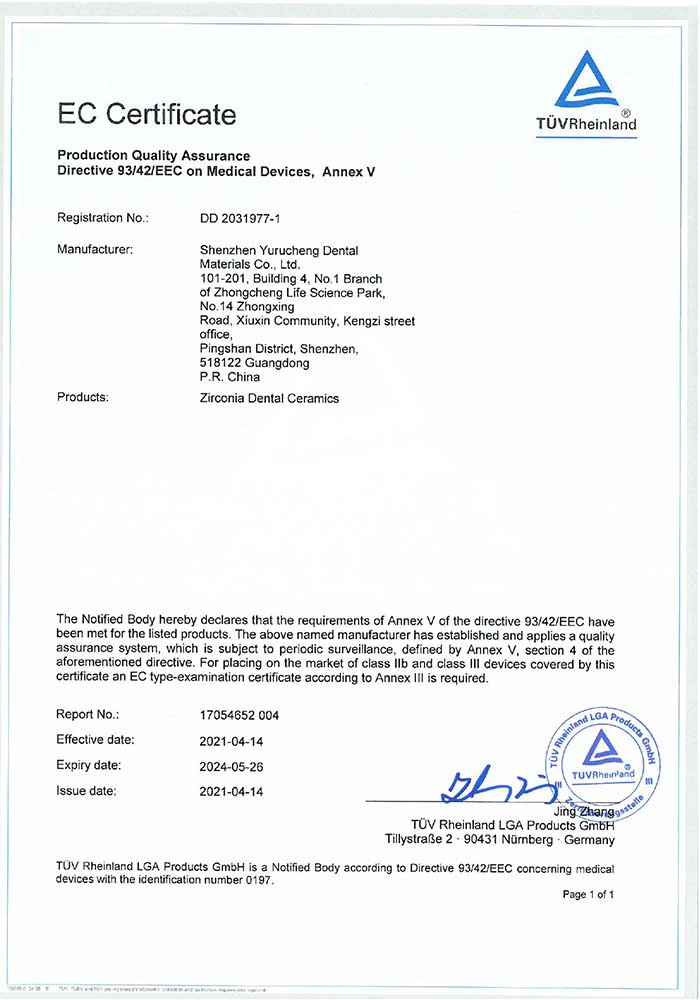

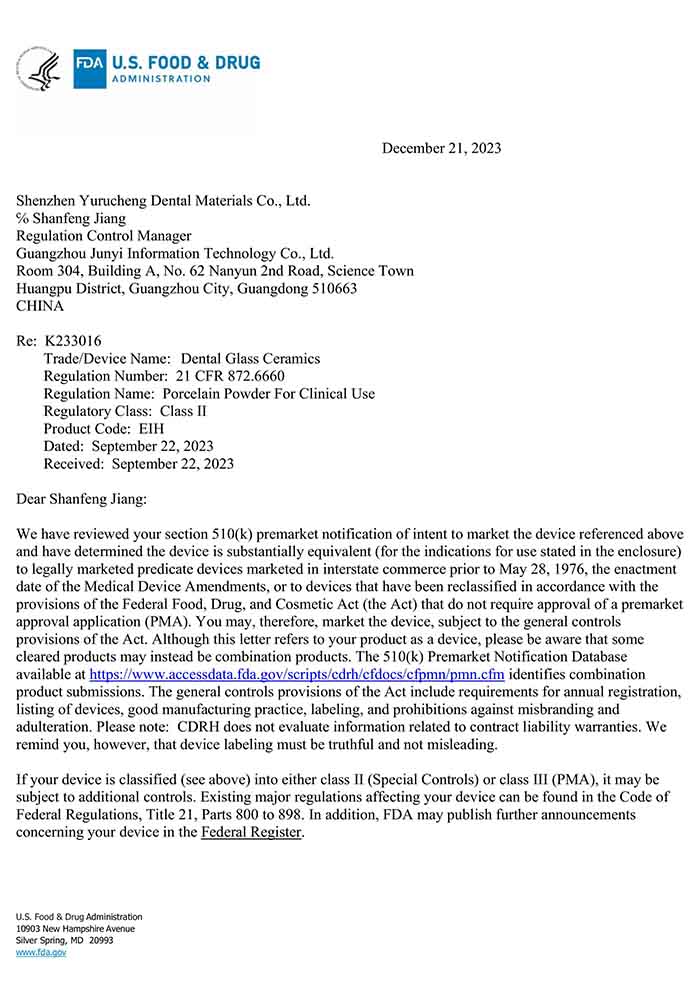

Certificates Istar Have Obtained

We’re a top-5 dental lab in China, CE & FDA & ISO certified, NADL member. 10 years of quality restorations, implants, and dentures. Your trusted dentistry partner.

What Our Doctor’s Say

"Istar Dental Lab's custom dental night guards have significantly improved our patients' satisfaction. The perfect fit and durability are unparalleled."

"Their range of custom dental appliances allows us to offer comprehensive solutions to our patients. The quality and service are excellent."

"We trust Istar Dental Lab for all our custom dental appliances. Their night guards for teeth grinding provide effective protection for our patients who grind or clench their teeth at night."

"Istar's commitment to precision and quality aligns with our practice standards. Their custom sports mouth guards are a great asset to our sports dentistry services."

"Partnering with Istar Dental Lab has been beneficial for us. Their efficient production process and advanced equipment ensure we receive top-notch products at a fraction of the cost."

Experience faster turnaround times with our cutting-edge technology

Latest from Blog

Explore dentistry trends, dental lab insights, digital dentistry updates, and tips for dentists on implants, crowns, restorations, and dental technology.

How Do Dentists Help the Community? Beyond the Chair and Into Everyday Life

When most people think about dentists, they picture a bright light, a reclining chair, and someone asking questions while…

How Do You Get Rid of Numbness From the Dentist? A Real-World Guide

Walking out of the dental office with half your face asleep is… not the vibe. You’re drooling a little,…

How Do I Choose a Dentist?

Choosing a dentist isn’t like choosing a new café. You’re literally handing someone sharp instruments, your health, your money,…